Climate Action 2011-2012

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

supply chain Management<br />

steps to sustainability<br />

Assessing the supply chain<br />

for efficient production, cost<br />

and reputation<br />

By Frances Way, Programme Director at the Carbon<br />

Disclosure Project (CDP)<br />

It makes good business sense to assess the supply chain<br />

for efficient production, cost and reputation. When this<br />

is done with an awareness of climate change impacts,<br />

it can uncover opportunities companies can capitalise<br />

on. A value chain approach is required and for this to<br />

be successful procurement teams and suppliers must<br />

be educated in the risks that climate change presents.<br />

Efficient use of energy in the supply chain can reduce<br />

operating costs. Measurement is key to driving efficiency;<br />

it not only provides a baseline but improves understanding<br />

and highlights opportunities for improvement. Supplier<br />

performance management should include greenhouse<br />

gas (GHG) emissions management, and this can be<br />

facilitated by scoring and benchmarking. Relationships<br />

between buyer and supplier have to be transparent and<br />

collaborative; your suppliers may hold the solutions.<br />

In order to avoid catastrophic climate change and respond<br />

to the challenge of increasingly scarce natural resources, we<br />

need to decouple economic growth from GHG emissions<br />

and move to a low carbon economy. Companies will be<br />

required to make both strategic and operational adjustments<br />

throughout their value chain by focusing on efficiency,<br />

transparency and performance management. It will be<br />

challenging but this is a predictable industrial revolution<br />

with significant opportunities that companies can plan to<br />

capitalise on. The management tools they require follow<br />

the same principles as those already used to assess efficient<br />

production, cost and reputation.<br />

The value chain approach<br />

A value chain approach to carbon management considers the<br />

impacts from production to consumption of a company’s<br />

products. Increasingly companies look beyond the invoice price<br />

of materials to consider the total acquisition costs associated<br />

with how the materials are handled, stored and disposed of.<br />

Taking a value chain approach to climate change impacts<br />

includes assessing the packaging, transport and processing of<br />

the materials. Volatile energy prices have motivated companies<br />

to focus on the energy use of their suppliers, and the energy<br />

efficiency of the products they provide to consumers. Imperial<br />

Tobacco Group in <strong>2011</strong> began to turn to suppliers’ Carbon<br />

Disclosure Project (CDP) reporting history to check their<br />

energy use and climate risk management, before granting<br />

price increases due to energy costs.<br />

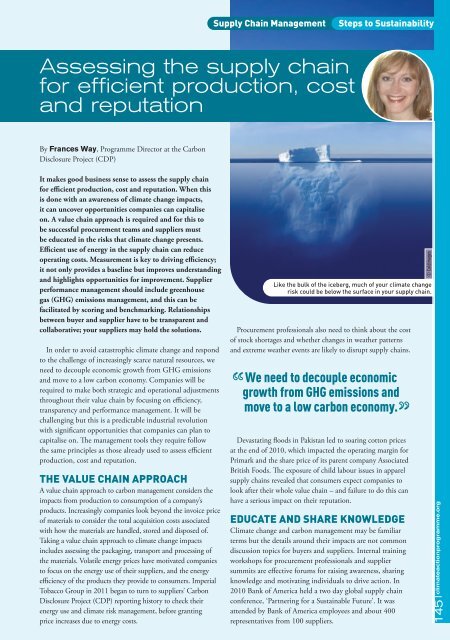

Like the bulk of the iceberg, much of your climate change<br />

risk could be below the surface in your supply chain.<br />

Procurement professionals also need to think about the cost<br />

of stock shortages and whether changes in weather patterns<br />

and extreme weather events are likely to disrupt supply chains.<br />

We need to decouple economic<br />

growth from GHG emissions and<br />

move to a low carbon economy.<br />

Devastating floods in Pakistan led to soaring cotton prices<br />

at the end of 2010, which impacted the operating margin for<br />

Primark and the share price of its parent company Associated<br />

British Foods. The exposure of child labour issues in apparel<br />

supply chains revealed that consumers expect companies to<br />

look after their whole value chain – and failure to do this can<br />

have a serious impact on their reputation.<br />

educaTe and share knowledge<br />

<strong>Climate</strong> change and carbon management may be familiar<br />

terms but the details around their impacts are not common<br />

discussion topics for buyers and suppliers. Internal training<br />

workshops for procurement professionals and supplier<br />

summits are effective forums for raising awareness, sharing<br />

knowledge and motivating individuals to drive action. In<br />

2010 Bank of America held a two day global supply chain<br />

conference, ‘Partnering for a Sustainable Future’. It was<br />

attended by Bank of America employees and about 400<br />

representatives from 100 suppliers.<br />

© Coldimages<br />

145 climateactionprogramme.org