cadera / hip - Active Congress.......

cadera / hip - Active Congress.......

cadera / hip - Active Congress.......

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MARTES / TUESDAY<br />

38<br />

lar component aseptic loosening<br />

- No component fracture or osteolysis<br />

- 9 Peripheral c<strong>hip</strong>s (2.6%) @ insertion<br />

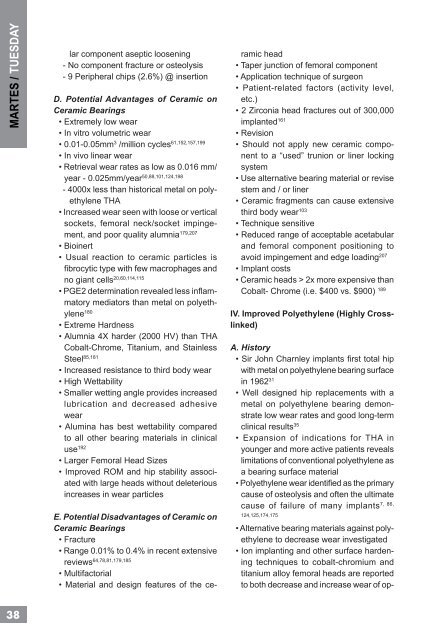

D. Potential Advantages of Ceramic on<br />

Ceramic Bearings<br />

• Extremely low wear<br />

• In vitro volumetric wear<br />

• 0.01-0.05mm 3 /million cycles 61,152,157,199<br />

• In vivo linear wear<br />

• Retrieval wear rates as low as 0.016 mm/<br />

year - 0.025mm/year 50,88,101,124,198<br />

- 4000x less than historical metal on polyethylene<br />

THA<br />

• Increased wear seen with loose or vertical<br />

sockets, femoral neck/socket impingement,<br />

and poor quality alumnia 179,207<br />

• Bioinert<br />

• Usual reaction to ceramic particles is<br />

fi brocytic type with few macrophages and<br />

no giant cells 20,60,114,115<br />

• PGE2 determination revealed less infl ammatory<br />

mediators than metal on polyethylene<br />

180<br />

• Extreme Hardness<br />

• Alumnia 4X harder (2000 HV) than THA<br />

Cobalt-Chrome, Titanium, and Stainless<br />

Steel 85,181<br />

• Increased resistance to third body wear<br />

• High Wettability<br />

• Smaller wetting angle provides increased<br />

lubrication and decreased adhesive<br />

wear<br />

• Alumina has best wettability compared<br />

to all other bearing materials in clinical<br />

use 192<br />

• Larger Femoral Head Sizes<br />

• Improved ROM and <strong>hip</strong> stability associated<br />

with large heads without deleterious<br />

increases in wear particles<br />

E. Potential Disadvantages of Ceramic on<br />

Ceramic Bearings<br />

• Fracture<br />

• Range 0.01% to 0.4% in recent extensive<br />

reviews 64,78,81,179,185<br />

• Multifactorial<br />

• Material and design features of the ce-<br />

ramic head<br />

• Taper junction of femoral component<br />

• Application technique of surgeon<br />

• Patient-related factors (activity level,<br />

etc.)<br />

• 2 Zirconia head fractures out of 300,000<br />

implanted 161<br />

• Revision<br />

• Should not apply new ceramic component<br />

to a “used” trunion or liner locking<br />

system<br />

• Use alternative bearing material or revise<br />

stem and / or liner<br />

• Ceramic fragments can cause extensive<br />

third body wear 103<br />

• Technique sensitive<br />

• Reduced range of acceptable acetabular<br />

and femoral component positioning to<br />

avoid impingement and edge loading 207<br />

• Implant costs<br />

• Ceramic heads > 2x more expensive than<br />

Cobalt- Chrome (i.e. $400 vs. $900) 189<br />

IV. Improved Polyethylene (Highly Crosslinked)<br />

A. History<br />

• Sir John Charnley implants fi rst total <strong>hip</strong><br />

with metal on polyethylene bearing surface<br />

in 196231 • Well designed <strong>hip</strong> replacements with a<br />

metal on polyethylene bearing demonstrate<br />

low wear rates and good long-term<br />

clinical results35 • Expansion of indications for THA in<br />

younger and more active patients reveals<br />

limitations of conventional polyethylene as<br />

a bearing surface material<br />

• Polyethylene wear identifi ed as the primary<br />

cause of osteolysis and often the ultimate<br />

7, 86,<br />

cause of failure of many implants<br />

124,125,174,175<br />

• Alternative bearing materials against polyethylene<br />

to decrease wear investigated<br />

• Ion implanting and other surface hardening<br />

techniques to cobalt-chromium and<br />

titanium alloy femoral heads are reported<br />

to both decrease and increase wear of op-