cadera / hip - Active Congress.......

cadera / hip - Active Congress.......

cadera / hip - Active Congress.......

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MARTES / TUESDAY<br />

40<br />

posing polyethylene…clinical applications<br />

presently unclear 44,135,140,170,184<br />

• Investigations of ceramic on polyethylene<br />

bearing surfaces overall report<br />

lower polyethylene wear rates, but results<br />

mixed 45,131,137,161,170<br />

• Early attempts to improve polyethylene<br />

(carbon- reinforced polyethylene, heatpressed<br />

polyethylene, and Hylamer)<br />

performed no better or worse than conventional<br />

polyethylene 33,119<br />

• Highly cross-linked polyethylene used in<br />

industrial applications (i.e. coal-chutes) is<br />

noted to improve wear resistance 136<br />

• Highly cross-linked medical grade polyethylene<br />

and techniques to decrease oxidation<br />

demonstrate signifi cantly reduced<br />

wear in <strong>hip</strong> simulator testing 133,146,209<br />

B. Design Issues<br />

• Cross-linking of Polyethylene<br />

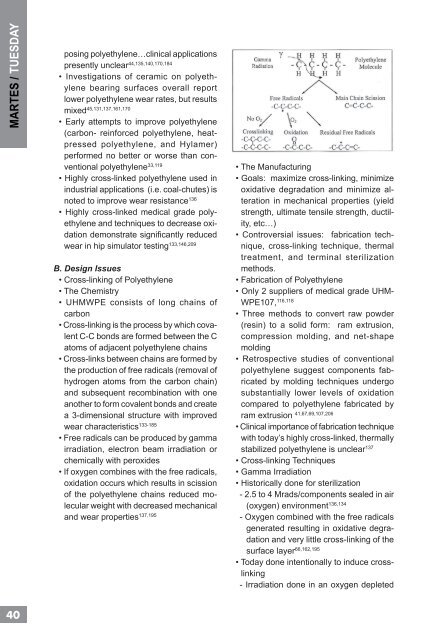

• The Chemistry<br />

• UHMWPE consists of long chains of<br />

carbon<br />

• Cross-linking is the process by which covalent<br />

C-C bonds are formed between the C<br />

atoms of adjacent polyethylene chains<br />

• Cross-links between chains are formed by<br />

the production of free radicals (removal of<br />

hydrogen atoms from the carbon chain)<br />

and subsequent recombination with one<br />

another to form covalent bonds and create<br />

a 3-dimensional structure with improved<br />

wear characteristics 133-185<br />

• Free radicals can be produced by gamma<br />

irradiation, electron beam irradiation or<br />

chemically with peroxides<br />

• If oxygen combines with the free radicals,<br />

oxidation occurs which results in scission<br />

of the polyethylene chains reduced molecular<br />

weight with decreased mechanical<br />

and wear properties 137,195<br />

• The Manufacturing<br />

• Goals: maximize cross-linking, minimize<br />

oxidative degradation and minimize alteration<br />

in mechanical properties (yield<br />

strength, ultimate tensile strength, ductility,<br />

etc…)<br />

• Controversial issues: fabrication technique,<br />

cross-linking technique, thermal<br />

treatment, and terminal sterilization<br />

methods.<br />

• Fabrication of Polyethylene<br />

• Only 2 suppliers of medical grade UHM-<br />

WPE107, 116,118<br />

• Three methods to convert raw powder<br />

(resin) to a solid form: ram extrusion,<br />

compression molding, and net-shape<br />

molding<br />

• Retrospective studies of conventional<br />

polyethylene suggest components fabricated<br />

by molding techniques undergo<br />

substantially lower levels of oxidation<br />

compared to polyethylene fabricated by<br />

ram extrusion 41,67,69,107,206<br />

• Clinical importance of fabrication technique<br />

with today’s highly cross-linked, thermally<br />

stabilized polyethylene is unclear 137<br />

• Cross-linking Techniques<br />

• Gamma Irradiation<br />

• Historically done for sterilization<br />

- 2.5 to 4 Mrads/components sealed in air<br />

(oxygen) environment 136,134<br />

- Oxygen combined with the free radicals<br />

generated resulting in oxidative degradation<br />

and very little cross-linking of the<br />

surface layer 66,162,195<br />

• Today done intentionally to induce crosslinking<br />

- Irradiation done in an oxygen depleted