The Geometry of Ships

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THE GEOMETRY OF SHIPS 19<br />

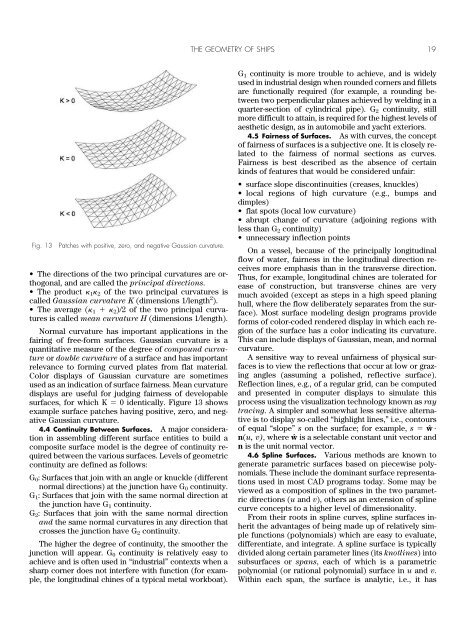

Fig. 13<br />

Patches with positive, zero, and negative Gaussian curvature.<br />

• <strong>The</strong> directions <strong>of</strong> the two principal curvatures are orthogonal,<br />

and are called the principal directions.<br />

• <strong>The</strong> product 1 2 <strong>of</strong> the two principal curvatures is<br />

called Gaussian curvature K (dimensions 1/length 2 ).<br />

• <strong>The</strong> average ( 1 2 )/2 <strong>of</strong> the two principal curvatures<br />

is called mean curvature H (dimensions 1/length).<br />

Normal curvature has important applications in the<br />

fairing <strong>of</strong> free-form surfaces. Gaussian curvature is a<br />

quantitative measure <strong>of</strong> the degree <strong>of</strong> compound curvature<br />

or double curvature <strong>of</strong> a surface and has important<br />

relevance to forming curved plates from flat material.<br />

Color displays <strong>of</strong> Gaussian curvature are sometimes<br />

used as an indication <strong>of</strong> surface fairness. Mean curvature<br />

displays are useful for judging fairness <strong>of</strong> developable<br />

surfaces, for which K 0 identically. Figure 13 shows<br />

example surface patches having positive, zero, and negative<br />

Gaussian curvature.<br />

4.4 Continuity Between Surfaces. A major consideration<br />

in assembling different surface entities to build a<br />

composite surface model is the degree <strong>of</strong> continuity required<br />

between the various surfaces. Levels <strong>of</strong> geometric<br />

continuity are defined as follows:<br />

G 0 : Surfaces that join with an angle or knuckle (different<br />

normal directions) at the junction have G 0 continuity.<br />

G 1 : Surfaces that join with the same normal direction at<br />

the junction have G 1 continuity.<br />

G 2 : Surfaces that join with the same normal direction<br />

and the same normal curvatures in any direction that<br />

crosses the junction have G 2 continuity.<br />

<strong>The</strong> higher the degree <strong>of</strong> continuity, the smoother the<br />

junction will appear. G 0 continuity is relatively easy to<br />

achieve and is <strong>of</strong>ten used in “industrial” contexts when a<br />

sharp corner does not interfere with function (for example,<br />

the longitudinal chines <strong>of</strong> a typical metal workboat).<br />

G 1 continuity is more trouble to achieve, and is widely<br />

used in industrial design when rounded corners and fillets<br />

are functionally required (for example, a rounding between<br />

two perpendicular planes achieved by welding in a<br />

quarter-section <strong>of</strong> cylindrical pipe). G 2 continuity, still<br />

more difficult to attain, is required for the highest levels <strong>of</strong><br />

aesthetic design, as in automobile and yacht exteriors.<br />

4.5 Fairness <strong>of</strong> Surfaces. As with curves, the concept<br />

<strong>of</strong> fairness <strong>of</strong> surfaces is a subjective one. It is closely related<br />

to the fairness <strong>of</strong> normal sections as curves.<br />

Fairness is best described as the absence <strong>of</strong> certain<br />

kinds <strong>of</strong> features that would be considered unfair:<br />

• surface slope discontinuities (creases, knuckles)<br />

• local regions <strong>of</strong> high curvature (e.g., bumps and<br />

dimples)<br />

• flat spots (local low curvature)<br />

• abrupt change <strong>of</strong> curvature (adjoining regions with<br />

less than G 2 continuity)<br />

• unnecessary inflection points<br />

On a vessel, because <strong>of</strong> the principally longitudinal<br />

flow <strong>of</strong> water, fairness in the longitudinal direction receives<br />

more emphasis than in the transverse direction.<br />

Thus, for example, longitudinal chines are tolerated for<br />

ease <strong>of</strong> construction, but transverse chines are very<br />

much avoided (except as steps in a high speed planing<br />

hull, where the flow deliberately separates from the surface).<br />

Most surface modeling design programs provide<br />

forms <strong>of</strong> color-coded rendered display in which each region<br />

<strong>of</strong> the surface has a color indicating its curvature.<br />

This can include displays <strong>of</strong> Gaussian, mean, and normal<br />

curvature.<br />

A sensitive way to reveal unfairness <strong>of</strong> physical surfaces<br />

is to view the reflections that occur at low or grazing<br />

angles (assuming a polished, reflective surface).<br />

Reflection lines, e.g., <strong>of</strong> a regular grid, can be computed<br />

and presented in computer displays to simulate this<br />

process using the visualization technology known as ray<br />

tracing. A simpler and somewhat less sensitive alternative<br />

is to display so-called “highlight lines,” i.e., contours<br />

<strong>of</strong> equal “slope” s on the surface; for example, s ŵ <br />

n(u, v), where ŵ is a selectable constant unit vector and<br />

n is the unit normal vector.<br />

4.6 Spline Surfaces. Various methods are known to<br />

generate parametric surfaces based on piecewise polynomials.<br />

<strong>The</strong>se include the dominant surface representations<br />

used in most CAD programs today. Some may be<br />

viewed as a composition <strong>of</strong> splines in the two parametric<br />

directions (u and v), others as an extension <strong>of</strong> spline<br />

curve concepts to a higher level <strong>of</strong> dimensionality.<br />

From their roots in spline curves, spline surfaces inherit<br />

the advantages <strong>of</strong> being made up <strong>of</strong> relatively simple<br />

functions (polynomials) which are easy to evaluate,<br />

differentiate, and integrate. A spline surface is typically<br />

divided along certain parameter lines (its knotlines) into<br />

subsurfaces or spans, each <strong>of</strong> which is a parametric<br />

polynomial (or rational polynomial) surface in u and v.<br />

Within each span, the surface is analytic, i.e., it has