VGB POWERTECH 5 (2021) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 5 (2021). Technical Journal of the VGB PowerTech Association. Energy is us! Nuclear power. Nuclear power plants - operation and operation experiences

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 5 (2021).

Technical Journal of the VGB PowerTech Association. Energy is us!

Nuclear power. Nuclear power plants - operation and operation experiences

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Residual <strong>Heat</strong> Removal Line (Redundancy)<br />

<strong>VGB</strong> PowerTech 5 l <strong>2021</strong><br />

Safety-related residual heat removal chains <strong>for</strong> pressure water reactors<br />

Development <strong>of</strong> safety-related residual<br />

heat removal chains from german<br />

technology pressure water reactors<br />

(light <strong>and</strong> heavy water)<br />

Franz Stuhlmüller <strong>and</strong> Rafael Macián-Juan<br />

Kurzfassung<br />

Entwicklung von sicherheitstechnischen<br />

Nachwärmeabfuhrpfaden für<br />

Druckwasserreaktoren deutscher<br />

Technologie (Leicht- und Schwerwasser)<br />

Die auf Entwicklungen in Deutschl<strong>and</strong> basierenden<br />

Druckwasserreaktor-KKW für angereicherten<br />

Brennst<strong>of</strong>f (PLWR) einerseits und für<br />

Natururan (PHWR) <strong>and</strong>ererseits sind in ihrer<br />

Basiskonzeption weitgehend identisch. Ein<br />

markanter Unterschied besteht jedoch im Umfang<br />

der Reaktorhauptsysteme. Während diese<br />

beim PLWR nur aus dem Reaktorkühl- und dessen<br />

Druckhalte- und Abblasesystem bestehen,<br />

kommt beim PHWR noch das Moderatorsystem<br />

hinzu, das im Leistungsbetrieb der Anlage den<br />

Moderator (Schwerwasser) permanent zu kühlen<br />

hat. Dieses verfahrenstechnische System<br />

wird in Zweitfunktion als innerstes Glied der<br />

sicherheitstechnisch wichtigen Nachkühlkette<br />

zur Wärmeabfuhr nach dem Abschalten des Reaktors<br />

verwendet. Während man beim PLWR –<br />

auch für die neuesten Anlagen – sowohl zum<br />

Abkühlen nach planmäßiger Abschaltung als<br />

auch zur Beherrschung der überwiegenden<br />

Zahl anzunehmender Störfalle in der ersten<br />

Zeit nach Schadenseintritt auf die weitere Bespeisung<br />

der Dampferzeuger angewiesen ist,<br />

wurde für den PHWR die Möglichkeit geschaffen,<br />

die Reaktorkühlung von Anfang an allein<br />

über die Nachkühlkette durchzuführen.<br />

Anh<strong>and</strong> der Statusprojekte beider Kraftwerkslinien<br />

dokumentieren sich nicht nur deren Einheitengrößen-Wachstum,<br />

sondern auch die<br />

Entwicklungs-Schritte ihrer Nachkühlketten-<br />

Technologie, die hier aufgezeigt wird. l<br />

Authors<br />

Franz Stuhlmüller<br />

External Scientific Associate at the Chair <strong>for</strong><br />

Nuclear Technology<br />

Technical University <strong>of</strong> Munich<br />

Pr<strong>of</strong>. Rafael Macián-Juan, PhD<br />

Head <strong>of</strong> the Chair <strong>of</strong> Nuclear Technology<br />

Technical University <strong>of</strong> Munich<br />

Munich, Germany<br />

Development <strong>of</strong> Safety-related Residual <strong>Heat</strong><br />

Removal Chains from German Technology<br />

Pressure Water Reactors I Franz Stuhlmüller<br />

Introduction<br />

The Nuclear Power Plants (NPPs) with<br />

Pressure Water Reactor <strong>for</strong> enriched fuel<br />

(PLWR, Pressurized Light Water Reactor)<br />

<strong>and</strong> <strong>for</strong> natural uranium (PHWR, Pressurized<br />

Heavy Water Reactor), developed in<br />

Germany, are largely identical in their basic<br />

design. However, there is a striking difference<br />

in the scope <strong>of</strong> the main reactor<br />

systems. While in PLWR these only consist<br />

<strong>of</strong> Reactor <strong>and</strong> Reactor Coolant System including<br />

Pressurizer <strong>and</strong> Pressurizer Relief<br />

Tank, in PHWR the Moderator System is<br />

added. In power operation <strong>of</strong> a PLWR, the<br />

entire thermal reactor power is transferred<br />

to the water/steam cycle via the Steam<br />

Generators. In PHWR, on the other h<strong>and</strong>,<br />

part <strong>of</strong> the power (approx. 10 %) has to be<br />

removed – at a lower temperature level –<br />

from the moderator, which is spatially separated<br />

from the main reactor coolant within<br />

the Reactor Pressure Vessel, but is kept<br />

at the same pressure via function-related<br />

Reactor<br />

2 1 1 1 1<br />

2 2 2<br />

3 3 3 3<br />

4 4 4 4<br />

5 5 5 5<br />

<strong>Heat</strong> Sink<br />

compensating openings. This portion <strong>of</strong><br />

power is used to preheat the feed water be<strong>for</strong>e<br />

it enters the Steam Generators. The<br />

Moderator System installed <strong>for</strong> this purpose<br />

can also be used in a second function<br />

as the inner link in the Residual <strong>Heat</strong> Removal<br />

Chain (RHRC) <strong>for</strong> cooling the reactor<br />

after it has been switched <strong>of</strong>f. In PLWR<br />

the analog system is operated exclusively<br />

<strong>for</strong> the removal <strong>of</strong> residual heat from the<br />

reactor <strong>and</strong>, if necessary, the fuel pool. In<br />

the following, the development <strong>of</strong> the<br />

RHRC <strong>of</strong> both NPP lines is shown <strong>and</strong> the<br />

main differences between both NPP-types<br />

in this regard are explained by comparing<br />

the most recently erected plants, DWR<br />

1,300 MW (KONVOI) <strong>and</strong> Atucha 2.<br />

Residual heat removal chain,<br />

structure <strong>and</strong> terms<br />

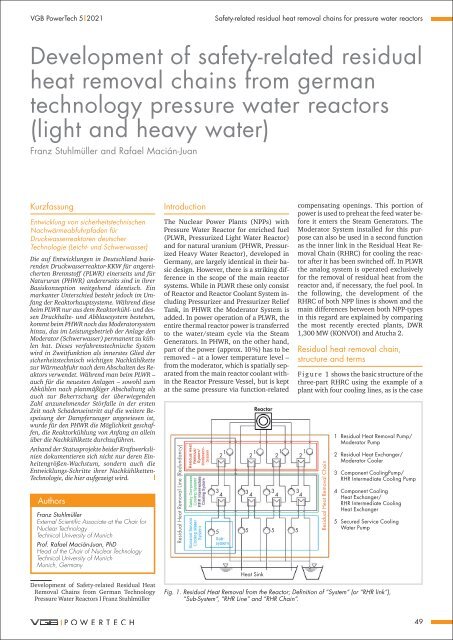

F i g u r e 1 shows the basic structure <strong>of</strong> the<br />

three-part RHRC using the example <strong>of</strong> a<br />

plant with four cooling lines, as is the case<br />

Residual <strong>Heat</strong> Removal Chain<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Residual <strong>Heat</strong> Removal Pump/<br />

Moderator Pump<br />

Residual <strong>Heat</strong> Exchanger/<br />

Moderator Cooler<br />

Component CoolingPump/<br />

RHR Intermediate Cooling Pump<br />

Component Cooling<br />

<strong>Heat</strong> Exchanger/<br />

RHR Intermediate Cooling<br />

<strong>Heat</strong> Exchanger<br />

Secured Service Cooling<br />

Water Pump<br />

Fig. 1. Residual <strong>Heat</strong> Removal from the Reactor; Definition <strong>of</strong> “System” (or “RHR link”),<br />

“Sub-System”, “RHR Line” <strong>and</strong> “RHR Chain”.<br />

49