VGB POWERTECH 5 (2021) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 5 (2021). Technical Journal of the VGB PowerTech Association. Energy is us! Nuclear power. Nuclear power plants - operation and operation experiences

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 5 (2021).

Technical Journal of the VGB PowerTech Association. Energy is us!

Nuclear power. Nuclear power plants - operation and operation experiences

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>VGB</strong> PowerTech 5 l <strong>2021</strong><br />

Safety-related residual heat removal chains <strong>for</strong> pressure water reactors<br />

Cooling System*. In this way, heat removal<br />

from the fuel pool is possible in principle<br />

via each <strong>of</strong> the four RHR lines.<br />

NPPs with Pressurized Heavy<br />

Water Reactors (PHWR)<br />

The function <strong>of</strong> the Moderator System in<br />

power operation <strong>of</strong> the plant requires identical<br />

pressure <strong>and</strong> temperature design values<br />

as <strong>for</strong> the Reactor Coolant System itself.<br />

However, this also opens up the possibility<br />

– by switching over valves inside the<br />

Moderator System <strong>and</strong> with an appropriate<br />

design <strong>of</strong> the RHR Intermediate Cooling<br />

System as the middle link <strong>of</strong> the RHRC – to<br />

take over the cooling <strong>of</strong> the reactor immediately<br />

after shut down, even without additional<br />

Steam Generator feed. This option<br />

has not yet been implemented <strong>for</strong> the<br />

MZFR as the first PHWR plant. Only CNA 1<br />

<strong>and</strong> CNA 2 are equipped with a high pressure/high<br />

temperature designed RHRC<br />

<strong>and</strong> are there<strong>for</strong>e independent <strong>of</strong> the function<br />

<strong>of</strong> the main heat sink (steam turbine<br />

condenser) <strong>for</strong> cooling down the plant after<br />

all shut-down occasions to be assumed.<br />

Multi-purpose research reactor Karlsruhe<br />

(MZFR), 50 MW el<br />

The shutdown concept <strong>of</strong> the MZFR basically<br />

corresponds to that <strong>of</strong> PLWR plants,<br />

with priority on the Steam Generators [11]<br />

(F i g u r e 7 ). Only when this – below a certain<br />

coolant temperature – is no longer<br />

thermodynamically possible, switch over<br />

to RHRC operation has to be per<strong>for</strong>med <strong>for</strong><br />

further cooling <strong>of</strong> the plant. Moderator<br />

temperature <strong>and</strong> heat to be removed at this<br />

time are already so low that the Moderator<br />

Cooler on its secondary side can be operated<br />

with inlet temperatures, which are accepted<br />

by the other cooling points without<br />

boiling at its outlet; even at the slight overpressure<br />

with which the Component cooling<br />

System is operated.<br />

A special feature <strong>of</strong> the MZFR-RHRC is that<br />

the operating pressure in the Secured Service<br />

Cooling Water is higher than in the<br />

Component Cooling System. In the event<br />

<strong>of</strong> a heat tube leak in the Component Cooling<br />

<strong>Heat</strong> Exchanger, transition <strong>of</strong> possibly<br />

radioactive contaminated water to the environment<br />

is thereby avoided, but pollution<br />

<strong>of</strong> the deionized water in the component<br />

cooling circuit may happen instead. In<br />

subsequent plants, the pressure gradation<br />

was implemented consistently from the<br />

heat source (high) to the heat sink (low).<br />

RCP<br />

SG<br />

Reactor<br />

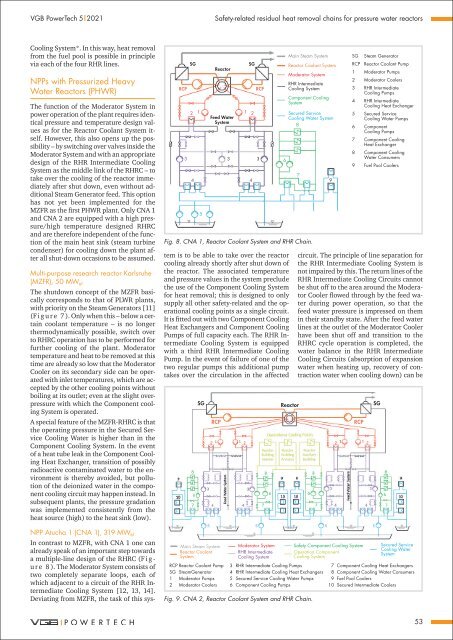

NPP Atucha 1 (CNA 1), 319 MW el<br />

In contrast to MZFR, with CNA 1 one can<br />

already speak <strong>of</strong> an important step towards<br />

a multiple-line design <strong>of</strong> the RHRC (F i g -<br />

u r e 8 ). The Moderator System consists <strong>of</strong><br />

two completely separate loops, each <strong>of</strong><br />

which adjacent to a circuit <strong>of</strong> the RHR Intermediate<br />

Cooling System [12, 13, 14].<br />

Deviating from MZFR, the task <strong>of</strong> this system<br />

is to be able to take over the reactor<br />

cooling already shortly after shut down <strong>of</strong><br />

the reactor. The associated temperature<br />

<strong>and</strong> pressure values in the system preclude<br />

the use <strong>of</strong> the Component Cooling System<br />

<strong>for</strong> heat removal; this is designed to only<br />

supply all other safety-related <strong>and</strong> the operational<br />

cooling points as a single circuit.<br />

It is fitted out with two Component Cooling<br />

<strong>Heat</strong> Exchangers <strong>and</strong> Component Cooling<br />

Pumps <strong>of</strong> full capacity each. The RHR Intermediate<br />

Cooling System is equipped<br />

with a third RHR Intermediate Cooling<br />

Pump. In the event <strong>of</strong> failure <strong>of</strong> one <strong>of</strong> the<br />

two regular pumps this additional pump<br />

takes over the circulation in the affected<br />

SG<br />

2 1 1 2<br />

Feed Water<br />

System<br />

3 3 3<br />

4 4<br />

5<br />

RCP<br />

6<br />

Main Steam System<br />

Reactor Coolant System<br />

Moderator System<br />

RHR Intermediate<br />

Cooling System<br />

Component Cooling<br />

System<br />

Secured Service<br />

Cooling Water System<br />

8<br />

Fig. 8. CNA 1, Reactor Coolant System <strong>and</strong> RHR Chain.<br />

7<br />

9<br />

SG Steam Generator<br />

RCP Reactor Coolant Pump<br />

1 Moderator Pumps<br />

2 Moderator Coolers<br />

3 RHR Intermediate<br />

Cooling Pumps<br />

4 RHR Intermediate<br />

Cooling <strong>Heat</strong> Exchanger<br />

5 Secured Service<br />

Cooling Water Pumps<br />

6 Component<br />

Cooling Pumps<br />

7 Component Cooling<br />

<strong>Heat</strong> Exchanger<br />

8 Component Cooling<br />

Water Consumers<br />

9 Fuel Pool Coolers<br />

circuit. The principle <strong>of</strong> line separation <strong>for</strong><br />

the RHR Intermediate Cooling System is<br />

not impaired by this. The return lines <strong>of</strong> the<br />

RHR Intermediate Cooling Circuits cannot<br />

be shut <strong>of</strong>f to the area around the Moderator<br />

Cooler flowed through by the feed water<br />

during power operation, so that the<br />

feed water pressure is impressed on them<br />

in their st<strong>and</strong>by state. After the feed water<br />

lines at the outlet <strong>of</strong> the Moderator Cooler<br />

have been shut <strong>of</strong>f <strong>and</strong> transition to the<br />

RHRC cycle operation is completed, the<br />

water balance in the RHR Intermediate<br />

Cooling Circuits (absorption <strong>of</strong> expansion<br />

water when heating up, recovery <strong>of</strong> contraction<br />

water when cooling down) can be<br />

SG Reactor SG<br />

RCP<br />

Main Steam System<br />

Reactor Coolant<br />

System<br />

RCP Reactor Coolant Pump<br />

SG SteamGenerator<br />

1 Moderator Pumps<br />

2 Moderator Coolers<br />

3<br />

4<br />

5<br />

6<br />

Moderator System Safety Component Cooling System Secured Service<br />

Cooling Water<br />

System<br />

RHR Intermediate<br />

Cooling System<br />

Operation Component<br />

Cooling System<br />

RHR Intermediate Cooling Pumps<br />

RHR Intermediate Cooling <strong>Heat</strong> Exchangers<br />

Secured Service Cooling Water Pumps<br />

Component Cooling Pumps<br />

Fig. 9. CNA 2, Reactor Coolant System <strong>and</strong> RHR Chain.<br />

RCP<br />

7 Component Cooling <strong>Heat</strong> Exchangers<br />

8 Component Cooling Water Consumers<br />

9 Fuel Pool Coolers<br />

10 Secured Intermediate Coolers<br />

53