VGB POWERTECH 5 (2021) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 5 (2021). Technical Journal of the VGB PowerTech Association. Energy is us! Nuclear power. Nuclear power plants - operation and operation experiences

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 5 (2021).

Technical Journal of the VGB PowerTech Association. Energy is us!

Nuclear power. Nuclear power plants - operation and operation experiences

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Inner Link<br />

Middle Link<br />

Outer Link<br />

<strong>VGB</strong> PowerTech 5 l <strong>2021</strong><br />

Safety-related residual heat removal chains <strong>for</strong> pressure water reactors<br />

DWR 1,300 MW<br />

Reactor<br />

CNA 2<br />

Reactor<br />

SG<br />

RCP<br />

SG<br />

RCP<br />

1 2<br />

6<br />

HPT<br />

FWT<br />

HPT<br />

FWT<br />

RH<br />

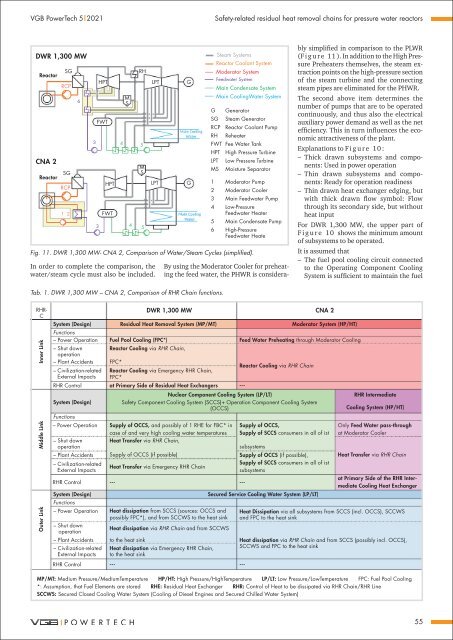

In order to complete the comparison, the<br />

water/steam cycle must also be included.<br />

3<br />

3<br />

M<br />

S<br />

4 5<br />

4<br />

M<br />

S<br />

5<br />

LPT<br />

LPT<br />

G<br />

G<br />

Steam Systems<br />

Reactor Coolant System<br />

Moderator System<br />

Feedwater System<br />

Main Condensate System<br />

Main CoolingWater System<br />

G<br />

SG<br />

RCP<br />

RH<br />

FWT<br />

HPT<br />

LPT<br />

MS<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

Generator<br />

Steam Generator<br />

Reactor Coolant Pump<br />

Reheater<br />

Fee Water Tank<br />

High Pressure Turbine<br />

Low Pressure Turbine<br />

Moisture Separator<br />

Moderator Pump<br />

Moderator Cooler<br />

Main Feedwater Pump<br />

Low-Pressure<br />

Feedwater <strong>Heat</strong>er<br />

Main Condensate Pump<br />

High-Pressure<br />

Feedwater <strong>Heat</strong>e<br />

Fig. 11. DWR 1,300 MW- CNA 2, Comparison <strong>of</strong> Water/Steam Cycles (simplified).<br />

By using the Moderator Cooler <strong>for</strong> preheating<br />

the feed water, the PHWR is considerably<br />

simplified in comparison to the PLWR<br />

(F i g u r e 11 ). In addition to the High Pressure<br />

Preheaters themselves, the steam extraction<br />

points on the high-pressure section<br />

<strong>of</strong> the steam turbine <strong>and</strong> the connecting<br />

steam pipes are eliminated <strong>for</strong> the PHWR.<br />

The second above item determines the<br />

number <strong>of</strong> pumps that are to be operated<br />

continuously, <strong>and</strong> thus also the electrical<br />

auxiliary power dem<strong>and</strong> as well as the net<br />

efficiency. This in turn influences the economic<br />

attractiveness <strong>of</strong> the plant.<br />

Explanations to F i g u r e 10 :<br />

––<br />

Thick drawn subsystems <strong>and</strong> components:<br />

Used in power operation<br />

––<br />

Thin drawn subsystems <strong>and</strong> components:<br />

Ready <strong>for</strong> operation readiness<br />

––<br />

Thin drawn heat exchanger edging, but<br />

with thick drawn flow symbol: Flow<br />

through its secondary side, but without<br />

heat input<br />

For DWR 1,300 MW, the upper part <strong>of</strong><br />

F i g u r e 10 shows the minimum amount<br />

<strong>of</strong> subsystems to be operated.<br />

It is assumed that<br />

––<br />

The fuel pool cooling circuit connected<br />

to the Operating Component Cooling<br />

System is sufficient to maintain the fuel<br />

Tab. 1. DWR 1,300 MW – CNA 2, Comparison <strong>of</strong> RHR Chain functions.<br />

RHR-<br />

C<br />

System (Design)<br />

Functions<br />

– Power Operation<br />

– Shut down<br />

operation<br />

– Plant Accidents<br />

– Civilization-related<br />

External Impacts<br />

RHR Control<br />

System (Design)<br />

Functions<br />

– Power Operation<br />

– Shut down<br />

operation<br />

– Plant Accidents<br />

– Civilization-related<br />

External Impacts<br />

RHR Control<br />

System (Design)<br />

Functions<br />

– Power Operation<br />

– Shut down<br />

operation<br />

– Plant Accidents<br />

– Civilization-related<br />

External Impacts<br />

RHR Control<br />

DWR 1,300 MW CNA 2<br />

Residual <strong>Heat</strong> Removal System (MP/MT)<br />

Fuel Pool Cooling (FPC*)<br />

Reactor Cooling via RHR Chain,<br />

FPC*<br />

Reactor Cooling via Emergency RHR Chain,<br />

FPC*<br />

at Primary Side <strong>of</strong> Residual <strong>Heat</strong> Exchangers<br />

Nuclear Component Cooling System (LP/LT)<br />

Safety Component Cooling System (SCCS)+ Operation Component Cooling System<br />

(OCCS)<br />

Supply <strong>of</strong> OCCS, <strong>and</strong> possibly <strong>of</strong> 1 RHE <strong>for</strong> FBC* in<br />

case <strong>of</strong> <strong>and</strong> very high cooling water temperatures<br />

<strong>Heat</strong> Transfer via RHR Chain,<br />

Supply <strong>of</strong> OCCS (if possible)<br />

<strong>Heat</strong> Transfer via Emergency RHR Chain<br />

---<br />

<strong>Heat</strong> dissipation from SCCS (sources: OCCS <strong>and</strong><br />

possibly FPC*), <strong>and</strong> from SCCWS to the heat sink<br />

<strong>Heat</strong> dissipation via RHR Chain <strong>and</strong> from SCCWS<br />

to the heat sink<br />

<strong>Heat</strong> dissipation via Emergency RHR Chain,<br />

to the heat sink<br />

---<br />

Secured Service Cooling Water System (LP/LT)<br />

Moderator System (HP/HT)<br />

Feed Water Preheating through Moderator Cooling<br />

Reactor Cooling via RHR Chain<br />

---<br />

Supply <strong>of</strong> OCCS,<br />

Supply <strong>of</strong> SCCS consumers in all <strong>of</strong> ist<br />

subsystems<br />

Supply <strong>of</strong> OCCS (if possible),<br />

Supply <strong>of</strong> SCCS consumers in all <strong>of</strong> ist<br />

subsystems<br />

---<br />

RHR Intermediate<br />

Cooling System (HP/HT)<br />

<strong>Heat</strong> Dissipation via all subsystems from SCCS (incl. OCCS), SCCWS<br />

<strong>and</strong> FPC to the heat sink<br />

<strong>Heat</strong> dissipation via RHR Chain <strong>and</strong> from SCCS (possibly incl. OCCS),<br />

SCCWS <strong>and</strong> FPC to the heat sink<br />

---<br />

Only Feed Water pass-through<br />

at Moderator Cooler<br />

<strong>Heat</strong> Transfer via RHR Chain<br />

at Primary Side <strong>of</strong> the RHR Intermediate<br />

Cooling <strong>Heat</strong> Exchanger<br />

MP/MT: Medium Pressure/MediumTemperature HP/HT: High Pressure/HighTemperature LP/LT: Low Pressure/LowTemperature FPC: Fuel Pool Cooling<br />

*: Assumption, that Fuel Elements are stored RHE: Residual <strong>Heat</strong> Exchanger RHR: Control <strong>of</strong> <strong>Heat</strong> to be dissipated via RHR Chain/RHR Line<br />

SCCWS: Secured Closed Cooling Water System (Cooling <strong>of</strong> Diesel Engines <strong>and</strong> Secured Chilled Water System)<br />

55