VGB POWERTECH 5 (2021) - International Journal for Generation and Storage of Electricity and Heat

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 5 (2021). Technical Journal of the VGB PowerTech Association. Energy is us! Nuclear power. Nuclear power plants - operation and operation experiences

VGB PowerTech - International Journal for Generation and Storage of Electricity and Heat. Issue 5 (2021).

Technical Journal of the VGB PowerTech Association. Energy is us!

Nuclear power. Nuclear power plants - operation and operation experiences

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Safety-related residual heat removal chains <strong>for</strong> pressure water reactors <strong>VGB</strong> PowerTech 5 l <strong>2021</strong><br />

a few safety-relevant additions – became<br />

the st<strong>and</strong>ard <strong>and</strong> has since been used <strong>for</strong> all<br />

following PLWR plants [5, 6]. The number<br />

<strong>of</strong> RHR lines usually, but not necessarily,<br />

corresponds to the number <strong>of</strong> reactor cooling<br />

loops. For this size <strong>of</strong> units (<strong>and</strong> also <strong>for</strong><br />

the EPR concept (≥ 1,600 MWel) four<br />

Steam Generators <strong>and</strong> thus four reactor<br />

cooling loops are required <strong>for</strong> heat transfer<br />

to the water/steam cycle in power operation.<br />

Accordingly, the RHRC also consists <strong>of</strong><br />

four independent RHR lines with a heat<br />

transfer capacity <strong>of</strong> 50 % each, based on the<br />

design case. (Note: Even <strong>for</strong> plants with<br />

only three reactor cooling loops, this “one<br />

to one” assignment <strong>of</strong> loop <strong>and</strong> line number<br />

can be obtained without violating the safety<br />

philosophy (repair <strong>and</strong> simultaneously<br />

single-failure) when the heat transfer capacity<br />

<strong>of</strong> each line is increased to 100 %.) In<br />

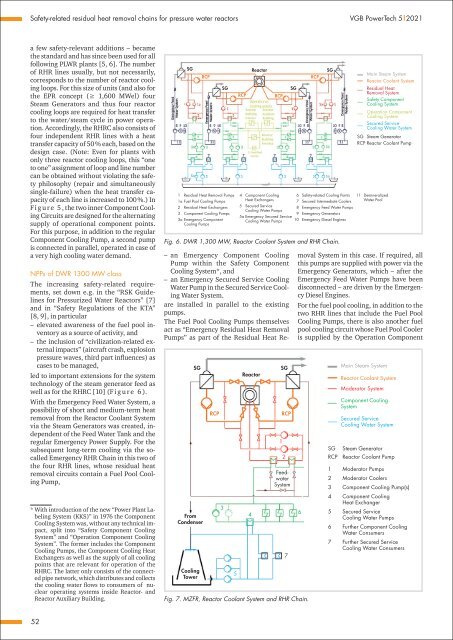

F i g u r e 5 , the two inner Component Cooling<br />

Circuits are designed <strong>for</strong> the alternating<br />

supply <strong>of</strong> operational component points.<br />

For this purpose, in addition to the regular<br />

Component Cooling Pump, a second pump<br />

is connected in parallel, operated in case <strong>of</strong><br />

a very high cooling water dem<strong>and</strong>.<br />

NPPs <strong>of</strong> DWR 1300 MW class<br />

The increasing safety-related requirements,<br />

set down e.g. in the “RSK Guidelines<br />

<strong>for</strong> Pressurized Water Reactors” [7]<br />

<strong>and</strong> in “Safety Regulations <strong>of</strong> the KTA”<br />

[8, 9], in particular<br />

––<br />

elevated awareness <strong>of</strong> the fuel pool inventory<br />

as a source <strong>of</strong> activity, <strong>and</strong><br />

––<br />

the inclusion <strong>of</strong> “civilization-related external<br />

impacts” (aircraft crash, explosion<br />

pressure waves, third part influences) as<br />

cases to be managed,<br />

led to important extensions <strong>for</strong> the system<br />

technology <strong>of</strong> the steam generator feed as<br />

well as <strong>for</strong> the RHRC [10] (F i g u r e 6 ).<br />

With the Emergency Feed Water System, a<br />

possibility <strong>of</strong> short <strong>and</strong> medium-term heat<br />

removal from the Reactor Coolant System<br />

via the Steam Generators was created, independent<br />

<strong>of</strong> the Feed Water Tank <strong>and</strong> the<br />

regular Emergency Power Supply. For the<br />

subsequent long-term cooling via the socalled<br />

Emergency RHR Chain in this two <strong>of</strong><br />

the four RHR lines, whose residual heat<br />

removal circuits contain a Fuel Pool Cooling<br />

Pump,<br />

* With introduction <strong>of</strong> the new “Power Plant Labeling<br />

System (KKS)” in 1976 the Component<br />

Cooling System was, without any technical impact,<br />

split into “Safety Component Cooling<br />

System” <strong>and</strong> “Operation Component Cooling<br />

System”. The <strong>for</strong>mer includes the Component<br />

Cooling Pumps, the Component Cooling <strong>Heat</strong><br />

Exchangers as well as the supply <strong>of</strong> all cooling<br />

points that are relevant <strong>for</strong> operation <strong>of</strong> the<br />

RHRC. The latter only consists <strong>of</strong> the connected<br />

pipe network, which distributes <strong>and</strong> collects<br />

the cooling water flows to consumers <strong>of</strong> nuclear<br />

operating systems inside Reactor- <strong>and</strong><br />

Reactor Auxiliary Building.<br />

SG<br />

RCP<br />

SG<br />

1 Residual <strong>Heat</strong> Removal Pumps<br />

1a Fuel Pool Cooling Pumps<br />

2 Residual <strong>Heat</strong> Exchangers<br />

3 Component Cooling Pumps<br />

3a Emergency Component<br />

Cooling Pumps<br />

RCP<br />

Reactor<br />

RCP<br />

4 Component Cooling<br />

<strong>Heat</strong> Exchangers<br />

5 Secured Service<br />

Cooling Water Pumps<br />

5a Emergency Secured Service<br />

Cooling Water Pumps<br />

SG<br />

RCP<br />

SG<br />

6 Safety-related Cooling Points<br />

7 Secured Intermediate Coolers<br />

8 Emergency Feed Water Pumps<br />

9 Emergency Generators<br />

10 Emergency Diesel Engines<br />

Fig. 6. DWR 1,300 MW, Reactor Coolant System <strong>and</strong> RHR Chain.<br />

SG<br />

From<br />

Condenser<br />

Cooling<br />

Tower<br />

RCP<br />

3<br />

5<br />

Reactor<br />

SG<br />

RCP<br />

Feedwater<br />

System<br />

Fig. 7. MZFR, Reactor Coolant System <strong>and</strong> RHR Chain.<br />

4<br />

1<br />

2<br />

7<br />

Main Steam System<br />

Reactor Coolant System<br />

Residual <strong>Heat</strong><br />

Removal System<br />

Safety Component<br />

Cooling System<br />

Operation Component<br />

Cooling System<br />

Secured Service<br />

Cooling Water System<br />

SG Steam Generator<br />

RCP Reactor Coolant Pump<br />

11 Demineralized<br />

Water Pool<br />

––<br />

an Emergency Component Cooling<br />

Pump within the Safety Component<br />

Cooling System*, <strong>and</strong><br />

––<br />

an Emergency Secured Service Cooling<br />

Water Pump in the Secured Service Cooling<br />

Water System.<br />

are installed in parallel to the existing<br />

pumps.<br />

The Fuel Pool Cooling Pumps themselves<br />

act as “Emergency Residual <strong>Heat</strong> Removal<br />

Pumps” as part <strong>of</strong> the Residual <strong>Heat</strong> Removal<br />

System in this case. If required, all<br />

this pumps are supplied with power via the<br />

Emergency Generators, which – after the<br />

Emergency Feed Water Pumps have been<br />

disconnected – are driven by the Emergency<br />

Diesel Engines.<br />

For the fuel pool cooling, in addition to the<br />

two RHR lines that include the Fuel Pool<br />

Cooling Pumps, there is also another fuel<br />

pool cooling circuit whose Fuel Pool Cooler<br />

is supplied by the Operation Component<br />

6<br />

SG<br />

RCP<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

Main Steam System<br />

Reactor Coolant System<br />

Moderator System<br />

Component Cooling<br />

System<br />

Secured Service<br />

Cooling Water System<br />

Steam Generator<br />

Reactor Coolant Pump<br />

Moderator Pumps<br />

Moderator Coolers<br />

Component Cooling Pump(s)<br />

Component Cooling<br />

<strong>Heat</strong> Exchanger<br />

Secured Service<br />

Cooling Water Pumps<br />

Further Component Cooling<br />

Water Consumers<br />

Further Secured Service<br />

Cooling Water Consumers<br />

52