Glanded Pumps - THERMO-ECO-ENGINEERING úvod

Glanded Pumps - THERMO-ECO-ENGINEERING úvod

Glanded Pumps - THERMO-ECO-ENGINEERING úvod

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Switching and Control Devices<br />

Planning Guide<br />

Pump performance Control<br />

Need for control<br />

Three main criteria, in line with the steady development of mechanical<br />

equipment for building services and the growing sensibility<br />

towards energy consumption, have led to the increased consideration<br />

of controls for utilisation in conjunction with heating pumps.<br />

1. Function optimisation<br />

Adjusting the pump capacity / heat flow to actual load demand, particularly<br />

to stabilise hydraulic conditions and to reduce circulating<br />

losses.<br />

2. Economic efficiency<br />

Reducing power consumption and operating costs, particularly in<br />

partial- or low-load operation (i.e. in over 80 % of the overall operating<br />

time).<br />

3. Comfort and convenience<br />

Avoiding system noise, in particular flow noise and noise in the thermostatic<br />

valves that are due to excessive flow and thermostatic radiator<br />

valves (TRV’s).<br />

Power savings in relation to reducing CO 2 emissions are in conjunction<br />

with environmental-protection considerations playing an ever<br />

more important role. It is widely known that generating power from<br />

fossil fuels produces significant levels of CO 2 emissions. In Germany<br />

engineers use the calculation principle that one kWh of current generated<br />

in a power station produces about 0.56 kg of CO 2 in the form<br />

of emissions.<br />

The decisive factor for concentrating studies on pumps in particular is<br />

their proportionally high share of power consumption within the<br />

energy balance of buildings.<br />

The causes for this are the high levels of operating hours as well as<br />

the familiar phenomenon of over-dimensioning heating pumps at the<br />

planning stage, factors which considerably add to the energy balance.<br />

Over-dimensioning by a factor of 2 to 5 times is the usual<br />

standard.<br />

Single-family house Large buildings<br />

<strong>Pumps</strong> account for 10 – 15 % of the overall<br />

power consumption, because...<br />

- Two to four pumps are available (heating /<br />

potable water circulation / accumulator<br />

charging, etc.) each pump with about<br />

1500 h to 5000 h operating time per year<br />

(depending on application), i.e. with three<br />

pumps on average:<br />

- 3 x 65 W x ca. 3500 h / a = ca. 700 kWh / a<br />

- In comparison: Mean statistically verified<br />

total power consumption of a singlefamily<br />

house:<br />

- about 5000 to 8000 kWh / a<br />

<strong>Pumps</strong> account for<br />

5 –8 % of the overall<br />

power consumption<br />

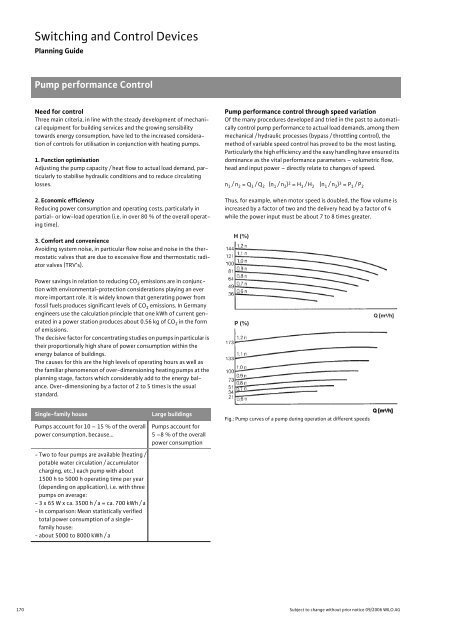

Pump performance control through speed variation<br />

Of the many procedures developed and tried in the past to automatically<br />

control pump performance to actual load demands, among them<br />

mechanical / hydraulic processes (bypass / throttling control), the<br />

method of variable speed control has proved to be the most lasting.<br />

Particularly the high efficiency and the easy handling have ensured its<br />

dominance as the vital performance parameters – volumetric flow,<br />

head and input power – directly relate to changes of speed.<br />

n 1 /n 2 = Q 1 /Q 2 (n 1 /n 2) 2 = H 1 /H 2 (n 1 /n 2) 3 = P 1 /P 2<br />

Thus, for example, when motor speed is doubled, the flow volume is<br />

increased by a factor of two and the delivery head by a factor of 4<br />

while the power input must be about 7 to 8 times greater.<br />

Q [m 3/h]<br />

Q [m<br />

Fig.: Pump curves of a pump during operation at different speeds<br />

3/h] Q [m3/h] 170 Subject to change without prior notice 09/2006 WILO AG<br />

H (%)<br />

P (%)