AREA A/B ENGINEERING REPORT - Waste Management

AREA A/B ENGINEERING REPORT - Waste Management

AREA A/B ENGINEERING REPORT - Waste Management

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.2 Liner System<br />

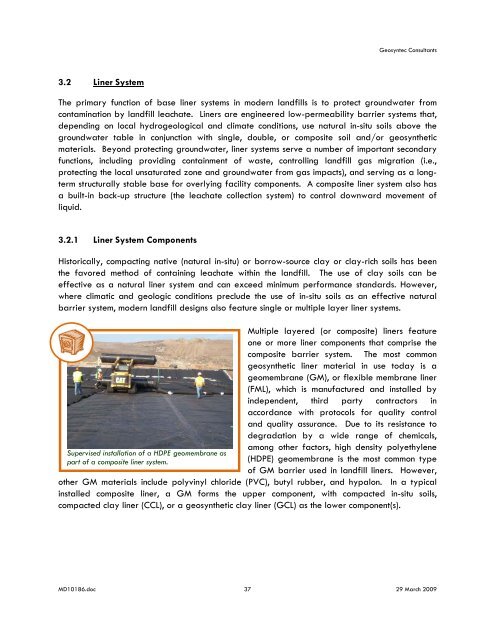

Supervised installation of a HDPE geomembrane as<br />

part of a composite liner system.<br />

Geosyntec Consultants<br />

The primary function of base liner systems in modern landfills is to protect groundwater from<br />

contamination by landfill leachate. Liners are engineered low-permeability barrier systems that,<br />

depending on local hydrogeological and climate conditions, use natural in-situ soils above the<br />

groundwater table in conjunction with single, double, or composite soil and/or geosynthetic<br />

materials. Beyond protecting groundwater, liner systems serve a number of important secondary<br />

functions, including providing containment of waste, controlling landfill gas migration (i.e.,<br />

protecting the local unsaturated zone and groundwater from gas impacts), and serving as a longterm<br />

structurally stable base for overlying facility components. A composite liner system also has<br />

a built-in back-up structure (the leachate collection system) to control downward movement of<br />

liquid.<br />

3.2.1 Liner System Components<br />

Historically, compacting native (natural in-situ) or borrow-source clay or clay-rich soils has been<br />

the favored method of containing leachate within the landfill. The use of clay soils can be<br />

effective as a natural liner system and can exceed minimum performance standards. However,<br />

where climatic and geologic conditions preclude the use of in-situ soils as an effective natural<br />

barrier system, modern landfill designs also feature single or multiple layer liner systems.<br />

Multiple layered (or composite) liners feature<br />

one or more liner components that comprise the<br />

composite barrier system. The most common<br />

geosynthetic liner material in use today is a<br />

geomembrane (GM), or flexible membrane liner<br />

(FML), which is manufactured and installed by<br />

independent, third party contractors in<br />

accordance with protocols for quality control<br />

and quality assurance. Due to its resistance to<br />

degradation by a wide range of chemicals,<br />

among other factors, high density polyethylene<br />

(HDPE) geomembrane is the most common type<br />

of GM barrier used in landfill liners. However,<br />

other GM materials include polyvinyl chloride (PVC), butyl rubber, and hypalon. In a typical<br />

installed composite liner, a GM forms the upper component, with compacted in-situ soils,<br />

compacted clay liner (CCL), or a geosynthetic clay liner (GCL) as the lower component(s).<br />

MD10186.doc 37 29 March 2009