Sfogliabile_InMotion_giugno_n34

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

tti<br />

Costantemente migliorate le<br />

caratteristiche dei cuscinetti<br />

Le caratteristiche dei cuscinetti FAG radiali rigidi<br />

a sfere Generation C, con forte presenza<br />

sul mercato già dal 2008, sono state costantemente<br />

migliorate. In particolare, sono state<br />

sviluppate due nuove soluzioni di tenuta,<br />

mentre minore perdita di grasso e migliore<br />

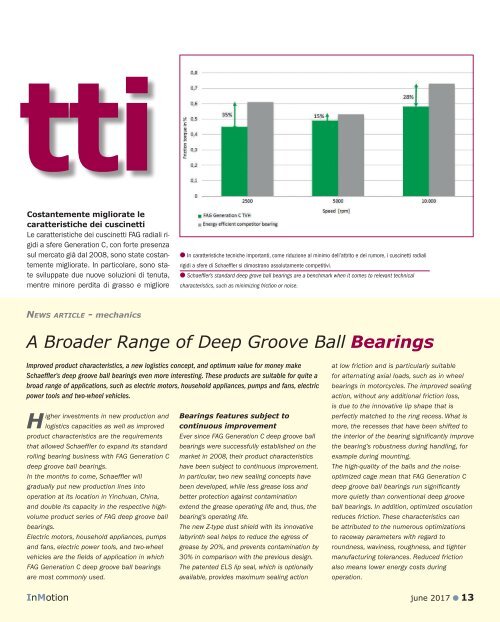

l In caratteristiche tecniche importanti, come riduzione al minimo dell’attrito e del rumore, i cuscinetti radiali<br />

rigidi a sfere di Schaeffler si dimostrano assolutamente competitivi.<br />

l Schaeffler’s standard deep grove ball bearings are a benchmark when it comes to relevant technical<br />

characteristics, such as minimizing friction or noise.<br />

NEWS ARTICLE - mechanics<br />

A Broader Range of Deep Groove Ball Bearings<br />

Improved product characteristics, a new logistics concept, and optimum value for money make<br />

Schaeffler’s deep groove ball bearings even more interesting. These products are suitable for quite a<br />

broad range of applications, such as electric motors, household appliances, pumps and fans, electric<br />

power tools and two-wheel vehicles.<br />

Higher investments in new production and<br />

logistics capacities as well as improved<br />

product characteristics are the requirements<br />

that allowed Schaeffler to expand its standard<br />

rolling bearing business with FAG Generation C<br />

deep groove ball bearings.<br />

In the months to come, Schaeffler will<br />

gradually put new production lines into<br />

operation at its location in Yinchuan, China,<br />

and double its capacity in the respective highvolume<br />

product series of FAG deep groove ball<br />

bearings.<br />

Electric motors, household appliances, pumps<br />

and fans, electric power tools, and two-wheel<br />

vehicles are the fields of application in which<br />

FAG Generation C deep groove ball bearings<br />

are most commonly used.<br />

<strong>InMotion</strong><br />

Bearings features subject to<br />

continuous improvement<br />

Ever since FAG Generation C deep groove ball<br />

bearings were successfully established on the<br />

market in 2008, their product characteristics<br />

have been subject to continuous improvement.<br />

In particular, two new sealing concepts have<br />

been developed, while less grease loss and<br />

better protection against contamination<br />

extend the grease operating life and, thus, the<br />

bearing’s operating life.<br />

The new Z-type dust shield with its innovative<br />

labyrinth seal helps to reduce the egress of<br />

grease by 20%, and prevents contamination by<br />

30% in comparison with the previous design.<br />

The patented ELS lip seal, which is optionally<br />

available, provides maximum sealing action<br />

at low friction and is particularly suitable<br />

for alternating axial loads, such as in wheel<br />

bearings in motorcycles. The improved sealing<br />

action, without any additional friction loss,<br />

is due to the innovative lip shape that is<br />

perfectly matched to the ring recess. What is<br />

more, the recesses that have been shifted to<br />

the interior of the bearing significantly improve<br />

the bearing’s robustness during handling, for<br />

example during mounting.<br />

The high-quality of the balls and the noiseoptimized<br />

cage mean that FAG Generation C<br />

deep groove ball bearings run significantly<br />

more quietly than conventional deep groove<br />

ball bearings. In addition, optimized osculation<br />

reduces friction. These characteristics can<br />

be attributed to the numerous optimizations<br />

to raceway parameters with regard to<br />

roundness, waviness, roughness, and tighter<br />

manufacturing tolerances. Reduced friction<br />

also means lower energy costs during<br />

operation.<br />

june 2017 l 13