- Page 2 and 3:

PERSPEKTIVA UGLJA KAO ENERGENTA THE

- Page 4 and 5:

Slika 3: Istorijska (1995-2000) i p

- Page 6 and 7:

konzuma biti 1,15% (napomena autora

- Page 8 and 9:

5. CENE UGLJA NA ENERGETSKIM TRŢI

- Page 10 and 11:

RAZVOJ RUDARSKOG KOMPLEKSA VELIKI K

- Page 12 and 13:

Površinski delovi su oksidisani (3

- Page 14 and 15:

50 200 2.2. Rudnik bakra Veliki Kri

- Page 16 and 17:

Zbog potrebne veće koliĉine konce

- Page 18 and 19:

PERSPEKTIVE RAZVOJA RUDNIKA BAKRA M

- Page 20 and 21:

2009. 2.372.510 7.792.510 5.882 473

- Page 22 and 23:

Stari Dušan Ruda (t) Cu% Cu (t) Au

- Page 24 and 25:

Rudno telo Ruda (t) Cu% Cu (t) Geol

- Page 26 and 27:

Rezime ODRŢAVANJE RUDARSKE OPREME

- Page 28 and 29:

Rotorni bager (reĊe se u tu svrhu

- Page 30 and 31:

površinskim kopovima, tj. već od

- Page 32 and 33: (pouzdanosti, gotovosti i pogodnost

- Page 34 and 35: Svaka kompanija definiše i analizi

- Page 36 and 37: Troškovi odrţavanja opreme prote

- Page 38 and 39: „praktiĉnog― odrţavanja rudar

- Page 40 and 41: Tabela 1. Rekapitulacija geoloških

- Page 42 and 43: dovoljno da se savlada materijal se

- Page 44 and 45: Tehnološki proces eksploatacije Za

- Page 46 and 47: Normativi materijala. Normativi mat

- Page 48 and 49: strukturno izuĉavanje leţišta ka

- Page 50 and 51: eksploatišemo i pripremamo duţi n

- Page 52 and 53: 2.1. Rudarski kompleks 2.1.1. Rudni

- Page 54 and 55: Na slici 7., dat je poloţaj objeka

- Page 56 and 57: podrazumeva više aktivnih otkopnih

- Page 58 and 59: izradom Glavnog servisnog niskopa (

- Page 60 and 61: Ukupna koliĉina raspoloţive rude

- Page 62 and 63: a) Specifiĉna potrošnja reagenasa

- Page 64 and 65: odvijati u pogonu flotacije Veliki

- Page 66 and 67: -Koncepcija zgušnjavanja i hidrotr

- Page 68 and 69: Da se rekonstrukcija postojećih te

- Page 70 and 71: PRIMENA ZAKONA O RUDARSTVU I GEOLO

- Page 72 and 73: u proces proizvodnje celokupnog otp

- Page 74 and 75: ODRŢIVO UPRAVLJANJE JALOVINOM U RU

- Page 76 and 77: - uvodi dvostepeni sistem za prevoz

- Page 78 and 79: porast sistemskog korišćenja ener

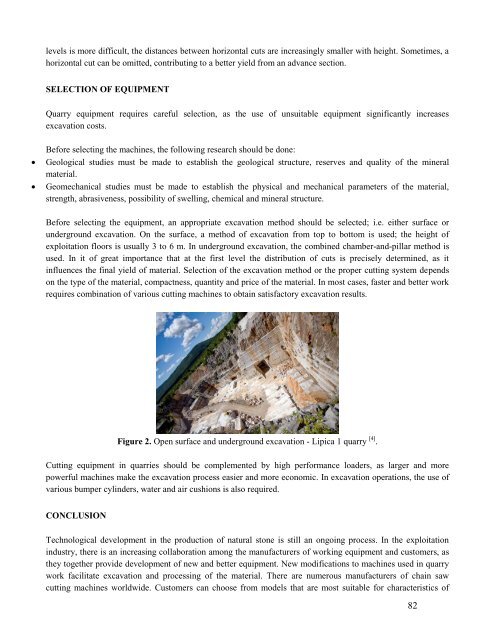

- Page 80 and 81: NATURAL STONE EXCAVATION PROCESS AN

- Page 84 and 85: their sites, their excavation prefe

- Page 86 and 87: elacija meĊu njima dok delikatnost

- Page 88 and 89: 3. Karakteristike rudarske delatnos

- Page 90 and 91: MINERALNE NAKNADE - ZABLUDE I POSLE

- Page 92 and 93: - Sve ove zemlje imaju vrlo razvije

- Page 94 and 95: predloţeno da se mineralna renta s

- Page 96 and 97: Izvod MOGUĆNOST DEPONOVANJA PEPELA

- Page 98 and 99: SITUACIJA TRASA CEVOVODA ZA HIDROTR

- Page 100 and 101: ANALIZA GEOLOŠKE ISTRAŢENOSTI RUD

- Page 102 and 103: Tabela 2 Izabrana leţišta sa rudn

- Page 104 and 105: B+C G Veliki Crljeni Sopic- Lazarev

- Page 106 and 107: B+C G Veliki Crljeni Sopic- Lazarev

- Page 108 and 109: eći sa 1.1 €cent/t). Saglasno na

- Page 110 and 111: Southern limit of the Zagorsko - La

- Page 112 and 113: detained and later was adopted and

- Page 114 and 115: examine the remaining reserves in t

- Page 116 and 117: vrijednosti (na bazi postojećih an

- Page 118 and 119: 8 - 8,5 24,2 13,8 8,5 - 9 13,8 27,6

- Page 120 and 121: TakoĊe, u geološkom stubu ugljeno

- Page 122 and 123: IZMJEŠTANJE DIJELA KORITA RIJEKE G

- Page 124 and 125: Slika 1. Šematski prikaz izrade os

- Page 126 and 127: Na fotografijama su priazane faze i

- Page 128 and 129: ANALIZA RADA SISTEMA ZA TRANSPORT U

- Page 130 and 131: Proizvodni kapacitet kopa iznosio j

- Page 132 and 133:

3.2. TEHNOLOGIJA RADA PRIMIJENJENOG

- Page 134 and 135:

Sati 10000 9000 8000 7000 6000 5000

- Page 136 and 137:

TEHNIĈKO -TEHNOLOŠKO REŠENJE UPR

- Page 138 and 139:

tok uglja Geolo{ki model le`i{ta MO

- Page 140 and 141:

Voz broj 423 Broj vagona 27 Koliĉi

- Page 142 and 143:

OCENA RIZIKA I NESIGURNOSTI U ZAŠT

- Page 144 and 145:

Koncept upravljanja rizikom se defi

- Page 146 and 147:

Tabela br. 2: Mesta nastanka otpadn

- Page 148 and 149:

U smislu usaglašenosti, poštovanj

- Page 150 and 151:

Zakljuĉak Ocena stanja ţivotne sr

- Page 152 and 153:

PRIMENA MODELA: HEMIJSKI LIZING NA

- Page 154 and 155:

Slika 5.- Pogonska stanica sa kosim

- Page 156 and 157:

Definisanje modela (definisanje jed

- Page 158 and 159:

Princip dejstva transportera sa pri

- Page 160 and 161:

kome se vrši dodatno drobljenje u

- Page 162 and 163:

(kamioni-ţeleznice-trake...). Duţ

- Page 164 and 165:

Uicaj kamionskog transporta. Štetn

- Page 166 and 167:

Opšti problem višekriterijumskog

- Page 168 and 169:

RAZVOJ ODRŢAVANJA POMOĆNE MEHANIZ

- Page 170 and 171:

Tabela 1. Klasifikacija procesa, ra

- Page 172 and 173:

.br Vrsta mašine Br. kom Vrsta ma

- Page 174 and 175:

DINAMIKA SERVISIRANJA I OPRAVKI MA

- Page 176 and 177:

R. Br. 2. Odredjivanje broja izradj

- Page 178 and 179:

REKAPITULACIJA POTREBNE RADNE SNAGE

- Page 180 and 181:

NEKI PROBLEMI TOKOM ZATVARNJA OTVOR

- Page 182 and 183:

Sitan lomljeni kamen ø 80 - 150 mm

- Page 184 and 185:

muljeve ograĊivao kamen krupnoće

- Page 186 and 187:

d) UKLJUĈENJE BAGERA DREGLAJNA U S

- Page 188 and 189:

Postoji velika razlika u kvalitetu

- Page 190 and 191:

1.3 Rudnik Nova Manasija - Zatvoren

- Page 192 and 193:

3.3 Rudnik Nova Manasija Tehnološk

- Page 194 and 195:

sl. br.1 Pregledna karta kolubarsko

- Page 196 and 197:

Plan rada Ia BTO sistema Na etaţi

- Page 198 and 199:

Plan rada BTS sistema Na etaţi BTS

- Page 200 and 201:

45000 45000 45000 45000 ? ?? ?? ??

- Page 202 and 203:

Tabela 1. Poĉetak i kraj rada BTO

- Page 204 and 205:

Slika 2. Konture rasprostiranja pod

- Page 206 and 207:

557,00 554,00 547,00 544,00 537,00

- Page 208 and 209:

Linija fronta ugljene etaţe stiţe

- Page 210 and 211:

znaĉajnijih aktivnosti. Dalje akti

- Page 212 and 213:

- gustine - temperature - brzine ve

- Page 214 and 215:

Slika 9. Model stepena doziranja te

- Page 216 and 217:

sistematskih istraţivanja u 1960.

- Page 218 and 219:

srednjezrn do sitnozrn bela G O R N

- Page 220 and 221:

Slika br. 1 Geološki stub dela le

- Page 222 and 223:

oblikovanja formirane su i naborne

- Page 224 and 225:

POVRATAK NA STARU LOKACIJU ODLAGALI

- Page 226 and 227:

1957 1958 1959 1960 1961 1962 1963

- Page 228 and 229:

225 Otkrivka iz prve faze odlaţe s

- Page 230 and 231:

?.5 1.5 ?.2 2.5 O-V ? .5 M6 ?.18 ?.

- Page 232 and 233:

ZATVARANJE RUDNIKA LIGNITA „BUKIN

- Page 234 and 235:

5. OBRAZLOŢENJE POTREBE ZATVARANJA

- Page 236 and 237:

a) Likvidacija otkopnog polja Otkop

- Page 238 and 239:

e) Prenamjena rudniĉkog ambijenta

- Page 240 and 241:

na neku konstantnu vrednost. To nij

- Page 242 and 243:

- Vaţnije rasede, pukotine, ponore

- Page 244 and 245:

trţište grejanja. U nemaĉkom rud

- Page 246 and 247:

Slika 5: Poloţaj Nordhausen-a u Ne

- Page 248 and 249:

Troškovi i vremenski rokovi koji s

- Page 250 and 251:

Osnovni nivo Osnovni nivo Slika 6:

- Page 252 and 253:

Tabela 2: Troškovi bušenja na jed

- Page 254 and 255:

UOPŠTENO O DUBLJENJU OKNA ZA HIDRO

- Page 256 and 257:

IZRADA POMOĆNOG OKNA USKOPNOM PLAT

- Page 258 and 259:

Slika 8: Fotografija radilišta na

- Page 260 and 261:

Slika 9: Poprečni presek prilaznog

- Page 262 and 263:

LITERATURA 1. Rudarski projekt za i

- Page 264 and 265:

N slika1. Pregledna geografska kart

- Page 266 and 267:

4.0. TEHNOLOGIJA OTKOPAVANJA OTKRIV

- Page 268 and 269:

Odlaganje kvartarnih glina Tabela b

- Page 270 and 271:

TEHNIĈKE KARAKTERISTIKE ODLAGAĈA

- Page 272 and 273:

Kamenolom ''Nepri~ava'' (kre~njak)

- Page 274 and 275:

ALUGA 114.0 1 0 98.8 1 0 693 2 730

- Page 276 and 277:

c) Izdan u peskovima gornjeg ponta.

- Page 278 and 279:

REKA KOLUBARA F AZA P.S 107.5 105 9

- Page 280 and 281:

KORELACONE VEZE MEĐU POJAVAMA KOLI

- Page 282 and 283:

2,100 1,900 1,700 1,500 1,300 rasip

- Page 284 and 285:

Za 1,095 (kolona 8): (1,095 - 1,447

- Page 286 and 287:

X Y X 2 Y 2 x x y y 2 x x y

- Page 288 and 289:

10. Zakljuĉak Na osnovu ispitivanj

- Page 290 and 291:

flore i faune na mestu odlaganja, b

- Page 292 and 293:

Slika 1. Geomorfološka mapa kostol

- Page 294 and 295:

Klaster 1 (n=3) Klaster 2 (n=6) Kla

- Page 296 and 297:

najkvalitetnijih sojeva za komercij

- Page 298 and 299:

FITOREMEDIJACIJA TEŠKIH METALA IZ

- Page 300 and 301:

Današnja tehnologija osnivanja zas

- Page 302 and 303:

POLJOPRIVREDNA PROIZVODNJA NA DEPOS

- Page 304 and 305:

Slika 2. Prirodno zemljište je pot

- Page 306 and 307:

hemijskih analiza treba istaći ned

- Page 308 and 309:

Slika 7 Što se tiĉe "Voćarske" p

- Page 310 and 311:

Figure 1: Ground plan of set up mon

- Page 312 and 313:

procedure takes into account the co

- Page 314 and 315:

The denominator in equation (17) is

- Page 316 and 317:

Accuracy comparison of the observat

- Page 318 and 319:

Number of valid observations [%] Š

- Page 320 and 321:

ANALIZA PRIRODNO-GEOLOŠKIH USLOVA

- Page 322 and 323:

Za pripremne rudarske prostorije, k

- Page 324 and 325:

Tabela 2. Overene rezerve uglja u n

- Page 326 and 327:

ANALIZA PROMENE HIDROGEOLOŠKIH USL

- Page 328 and 329:

NO 2 manje od 0,01 pH 7,35 Ukupna m

- Page 330 and 331:

Slika 3: Situacioni deo OP-1 i OP-4

- Page 332 and 333:

METODOLOGIJA UVOĐENJA NOVIH METODA

- Page 334 and 335:

Zbog toga je za otkopavanje ove gru

- Page 336 and 337:

Rez ult ati/ Me sec: R. Av br. gus

- Page 338 and 339:

R. br . 1. Tabela br.2: Potrošnja

- Page 340 and 341:

PREGLED POSTOJEĆEG STANJA 1.1. Teh

- Page 342 and 343:

PREDLOG METODOLOGIJE ODREĐIVANJA C

- Page 344 and 345:

NAĈIN OTVARANJA, RAZRADE I EKSPLOA

- Page 346 and 347:

• Padni ugao ugljenog sloja se me

- Page 348 and 349:

Slika 3. Karakteristiĉni profil ug

- Page 350 and 351:

dela leţista, sa usmerenjem prema

- Page 352 and 353:

Generalno gledano otkopavanje uglje

- Page 354 and 355:

UTICAJ NA ŢIVOTNU SREDINU ZVUĈNIH

- Page 356 and 357:

Za vazdušni udrani talas karakteri

- Page 358 and 359:

4.1. Seizmiĉko dejstvo Na bazi eks

- Page 360 and 361:

Slika 6. Trenutna miniranja: Funkci

- Page 362 and 363:

Na slici 8. prikazani su segmenti e

- Page 364 and 365:

PRAĆENJE UTICAJA RUDARSKIH RADOVA

- Page 366 and 367:

c) Površinski (površine radnih i

- Page 368 and 369:

4) Dostupnost elektriĉne energije

- Page 370 and 371:

GEODETSKE TEHNOLOGIJE I MERENJA U R

- Page 372 and 373:

koja se moţe postići u statiĉkom

- Page 374 and 375:

- Kontrola geometrije rudarske opre

- Page 376 and 377:

GEORADARSKI INSTRUMENT pulseEKKO PR

- Page 378 and 379:

PROBLEMATIKA I REZULTATI PRIMJENE M

- Page 380 and 381:

Geoelektriĉnim snimanjem dodatno s

- Page 382 and 383:

Slika br. 12. - Detaljna georadarsk

- Page 384 and 385:

Mestimiĉno rekristališe u bornit.

- Page 386 and 387:

Zeta potencijal ; mV Iskorišćenje

- Page 388 and 389:

IMPLEMENTACIJA PROCESA STABILIZACIJ

- Page 390 and 391:

odreĊena jednostavnom metodom mere

- Page 392 and 393:

4. Rezultati 4.1. Karakterizacija o

- Page 394 and 395:

RUDNIĈKE VODE IZ RUDNIKA RTB BOR -

- Page 396 and 397:

Tabela 1 Rudniĉke vode rudnika RBB

- Page 398 and 399:

nepovratno gubi. Jama Bor će posto

- Page 400 and 401:

korita reke Mali Pek u duţini 850

- Page 402 and 403:

Slika 2. Prikaz trase puta i daleko

- Page 404 and 405:

IZMENJENA TEHNOLOGIJA OTKOPAVANJA

- Page 406 and 407:

Za izvoĊenje rudarskih radova na o

- Page 408 and 409:

ISLUSTVA SA STABILIZACIJOM I SOLIDI

- Page 410 and 411:

sabijanja u veoma prihvatljivom obl

- Page 412 and 413:

Uzorkovanje se vršilo toko ĉitavo

- Page 414 and 415:

Slika 1. Prva izlivena anoda od maj

- Page 416 and 417:

Slika 5. Površinski kop Severni re

- Page 418 and 419:

Lokacije mernih profila deponovanog

- Page 420 and 421:

IZVOD IZBOR KVALITETA GUMENE TRAKE

- Page 422 and 423:

Slika br.3: Izgled trakastog dodava

- Page 424 and 425:

Slika br.7: Izgled oblika korita po

- Page 426 and 427:

EKOGEOHEMIJSKA ISPITIVANA ZA POTREB

- Page 428 and 429:

otpada pomoću TCLP metode. Pored g

- Page 430 and 431:

Tabela 2: Sadrţaji teških metala

- Page 432 and 433:

TRETMAN OTPADNIH VODA IZ KOPOVA “

- Page 434 and 435:

3. REZULTATI I DISKUSIJA Nastavak e

- Page 436 and 437:

gornje jure, muskovitskih škriljac

- Page 438 and 439:

ZNAĈAJ INFORMATIĈKE OBRADE GEOLO

- Page 440 and 441:

stepeni.Iz tih razloga razumljivo j

- Page 442 and 443:

500 400 300 200 100 0 -100 -200 0 2

- Page 444 and 445:

ISPITIVANJE UNAPREĐENIH ELEKTROKIN

- Page 446 and 447:

emedijacije se zasniva na tome da s

- Page 448 and 449:

Slika 2. Distribucija metala u sedi

- Page 450 and 451:

PRIMENA KOMPJUTERSKOG PROGRAMA GIS

- Page 452 and 453:

Slika 1. Digitalizovana situaciona

- Page 454 and 455:

3. ZAKLJUĈCI Primenom kompjuteriza

- Page 456 and 457:

TEHNIĈKI OPIS SISTEMA VAZDUŠNIH R

- Page 458 and 459:

-Ukoliko se primeti da su ĉašice

- Page 460 and 461:

Usvaja se cev za razvod komprimiran

- Page 462 and 463:

Ci Ce 100 (1) Ci gde je: α - s

- Page 464 and 465:

iz rastvora Cu(NO 3 ) 2 ostvaren za

- Page 466 and 467:

a) b) Slika 2. Desorpcija jona (a)

- Page 468 and 469:

ADSORPCIJA JONA Pb 2+ IZ SINTETIĈK

- Page 470 and 471:

2.3. Metode analize Za odreĊivanje

- Page 472 and 473:

a) Slika 4. a) Adsorpciona izoterma

- Page 474 and 475:

UVOĐENJE KOMERCIJALNOG POSTROJENJA

- Page 476 and 477:

Slika 2. Šemtski prikaz luţenja g

- Page 478 and 479:

MS x +Fe 3+ Hemijski M x+ +Fe 2+

- Page 480 and 481:

Literatura [1] Johnson D.B., Biohyd

- Page 482 and 483:

spaljena a potom ţarena na 815°C.

- Page 484 and 485:

Slika 3. Kinetiĉki model pseudo-dr

- Page 486 and 487:

TEHNIĈKA REKULTIVACIJA DEGRADIRANI

- Page 488 and 489:

Slika 2. Poprečni profili 1 -5 i

- Page 490 and 491:

Tabela 4 - Granulometrijska analiza

- Page 492 and 493:

3. R.Lekovski, M.Mikić, M.Martinov

- Page 494 and 495:

ANDENZITSKI PRST ISTOĈNO ODLAGALI

- Page 496 and 497:

Slika 3. 3D prikaz Istoĉnog odlaga

- Page 498 and 499:

Površine flotacijskog jalovišta

- Page 500 and 501:

HIDROGEOLOŠKE KARAKTERISTIKE LEŢI

- Page 502 and 503:

podzemnih voda. Kada se eksploataci

- Page 504 and 505:

leţišta gde je kreĉnjaĉka stens

- Page 506 and 507:

Slika 10 - Uprošćena geološka ka

- Page 508 and 509:

NEMETALIĈNE MINERALNE SIROVINE - P

- Page 510 and 511:

Kolicina adsorbovanog aresenata, mg

- Page 512 and 513:

Sa Slike 3 se moţe videti da je i

- Page 514 and 515:

Hercegovine. Pomijeranjem masa u kl

- Page 516 and 517:

Slika 4. Velika livada u vršnom di

- Page 518 and 519:

površinskom dijelu, stijene ovog k

- Page 520 and 521:

FORMIRANJE SIROVINSKE DEPONIJE OPTI

- Page 522 and 523:

Sirovinski deo obuhvata les, glinu,

- Page 524 and 525:

14,65 9,1 3,6 7,84 min 19,88 17,2 3

- Page 526 and 527:

sadrţaja CaCO 3 od 13,26% (vrednos

- Page 528 and 529:

REZULTATI HIDROGEOLOŠKIH I INŢENJ

- Page 530 and 531:

deponija je formirana u uvali nasta

- Page 532 and 533:

STRATEGIJA SMANJENJA GLOBALNOG ZAGR

- Page 534 and 535:

3. Kjoto protokol Slika 2. Odstupan

- Page 536 and 537:

Krive graniĉnog troška kontrole M

- Page 538 and 539:

Tabela 1. Terminski ugovor Datum tr

- Page 540 and 541:

METODOLOŠKI OKVIR IDENTIFIKACIJE A

- Page 542 and 543:

2.3. Opis proizvodnog procesa i nje

- Page 544 and 545:

3.2.1. Matriĉni metod procene rizi

- Page 546 and 547:

4.2. Princip vrednovanja stvarnih i

- Page 548 and 549:

5. ZAKLJUĈAK Iz priloţenih istra

- Page 550 and 551:

Sl.1 Geografski poloţaj kamenoloma

- Page 552 and 553:

Srednji koeficijent otkrivke iznosi

- Page 554 and 555:

Prednost projektovanja u 3D okruţe

- Page 556 and 557:

THE POSSIBLE USE OF FLY ASH FROM TH

- Page 558 and 559:

Treći vid primene je u izradi gra

- Page 560 and 561:

G L A V N E S T R U K T U R E D I N

- Page 562 and 563:

Predmetna istraţna polja spadaju u

- Page 564 and 565:

KARAKTERIZACIJA KAOLINSKE GLINE IZ

- Page 566 and 567:

Gubitak mase, % DTA, V Slika 7. Dif

- Page 568 and 569:

TEHNOLOGIJA IZVOĐENJA BUŠAĈKO-MI

- Page 570 and 571:

paralelan autoputu, širine 6m i im

- Page 572 and 573:

„uklanjanja― bouldera sa trase

- Page 574:

obavezan nadzor inspektora policije