Summary of Rubber Modified Asphalt Product Specifications around ...

Summary of Rubber Modified Asphalt Product Specifications around ...

Summary of Rubber Modified Asphalt Product Specifications around ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

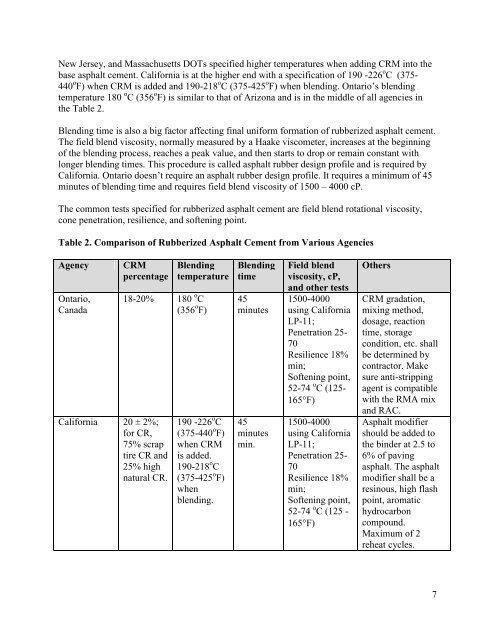

New Jersey, and Massachusetts DOTs specified higher temperatures when adding CRM into the<br />

base asphalt cement. California is at the higher end with a specification <strong>of</strong> 190 -226 o C (375-<br />

440 o F) when CRM is added and 190-218 o C (375-425 o F) when blending. Ontario’s blending<br />

temperature 180 o C (356 o F) is similar to that <strong>of</strong> Arizona and is in the middle <strong>of</strong> all agencies in<br />

the Table 2.<br />

Blending time is also a big factor affecting final uniform formation <strong>of</strong> rubberized asphalt cement.<br />

The field blend viscosity, normally measured by a Haake viscometer, increases at the beginning<br />

<strong>of</strong> the blending process, reaches a peak value, and then starts to drop or remain constant with<br />

longer blending times. This procedure is called asphalt rubber design pr<strong>of</strong>ile and is required by<br />

California. Ontario doesn’t require an asphalt rubber design pr<strong>of</strong>ile. It requires a minimum <strong>of</strong> 45<br />

minutes <strong>of</strong> blending time and requires field blend viscosity <strong>of</strong> 1500 – 4000 cP.<br />

The common tests specified for rubberized asphalt cement are field blend rotational viscosity,<br />

cone penetration, resilience, and s<strong>of</strong>tening point.<br />

Table 2. Comparison <strong>of</strong> <strong>Rubber</strong>ized <strong>Asphalt</strong> Cement from Various Agencies<br />

Agency CRM<br />

percentage<br />

Ontario,<br />

Canada<br />

Blending<br />

temperature<br />

18-20% 180 o C<br />

(356 o F)<br />

California 20 ± 2%;<br />

for CR,<br />

75% scrap<br />

tire CR and<br />

25% high<br />

natural CR.<br />

190 -226 o C<br />

(375-440 o F)<br />

when CRM<br />

is added.<br />

190-218 o C<br />

(375-425 o F)<br />

when<br />

blending.<br />

Blending<br />

time<br />

45<br />

minutes<br />

45<br />

minutes<br />

min.<br />

Field blend<br />

viscosity, cP,<br />

and other tests<br />

1500-4000<br />

using California<br />

LP-11;<br />

Penetration 25-<br />

70<br />

Resilience 18%<br />

min;<br />

S<strong>of</strong>tening point,<br />

52-74 o C (125-<br />

165F)<br />

1500-4000<br />

using California<br />

LP-11;<br />

Penetration 25-<br />

70<br />

Resilience 18%<br />

min;<br />

S<strong>of</strong>tening point,<br />

52-74 o C (125 -<br />

165F)<br />

Others<br />

CRM gradation,<br />

mixing method,<br />

dosage, reaction<br />

time, storage<br />

condition, etc. shall<br />

be determined by<br />

contractor. Make<br />

sure anti-stripping<br />

agent is compatible<br />

with the RMA mix<br />

and RAC.<br />

<strong>Asphalt</strong> modifier<br />

should be added to<br />

the binder at 2.5 to<br />

6% <strong>of</strong> paving<br />

asphalt. The asphalt<br />

modifier shall be a<br />

resinous, high flash<br />

point, aromatic<br />

hydrocarbon<br />

compound.<br />

Maximum <strong>of</strong> 2<br />

reheat cycles.<br />

7