19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3 - INSTALLATION<br />

3.1 - Introduction<br />

The <strong>19XR</strong> machine is factory assembled, wired, leak tested<br />

and electrically tested. Installation (not by <strong>Carrier</strong>) consists<br />

primarily of establishing water and electrical services to the<br />

machine. The rigging, installation, field wiring, field piping,<br />

and insulation of waterbox covers are the responsibilty of the<br />

contractor and/or customer. <strong>Carrier</strong> has no installation<br />

responsibilities for the equipment.<br />

3.2 - Receiving the machine<br />

3.2.1 - Inspect shipment<br />

CAUTION: Do not open any valves or loosen any connections.<br />

The standard <strong>19XR</strong> machine is shipped with a full refrigerant<br />

charge. Some machines may be shipped with a nitrogen holding<br />

charge as an option.<br />

Inspect for shipping damage while machine is still on<br />

shipping conveyance. If machine appears to be damaged or has<br />

been torn loose from its anchorage, have it examined by<br />

transportation inspectors before removal. Forward claim<br />

papers directly to transportation company. Manufacturer is<br />

not responsible for any damage incurred in transit.<br />

Confirm that the unit received is the one ordered. Compare<br />

the name plate data with the order.<br />

The unit name plate must include the following<br />

information:<br />

- Version number<br />

- Model number<br />

- CE marking<br />

- Serial number<br />

- Year of manufacture and test date<br />

- Refrigerant used and refrigerant class<br />

- Refrigerant charge per circuit<br />

- Containment fluid to be used<br />

- PS: Min./max. allowable pressure (high and low<br />

pressure side)<br />

- TS: Min./max. allowable temperature (high and low<br />

pressure side)<br />

- Globe valve cut-out pressure<br />

- Pressure switch cut-out pressure<br />

- Unit leak test pressure<br />

- Voltage, frequency, number of phases<br />

- Maximum current drawn<br />

- Maximum power input<br />

- Unit net weight<br />

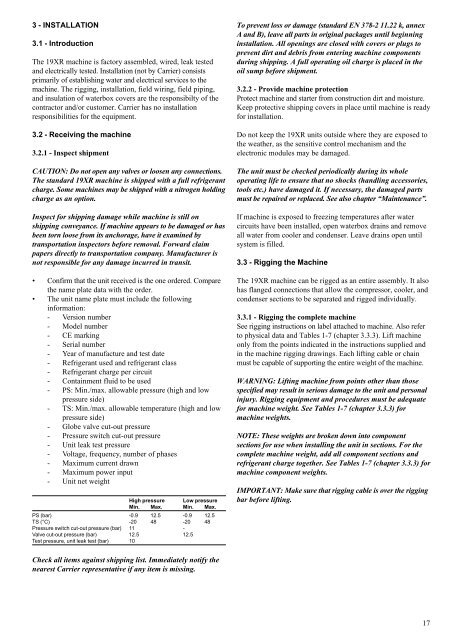

High pressure Low pressure<br />

Min. Max. Min. Max.<br />

PS (bar) -0.9 12.5 -0.9 12.5<br />

TS (°C) -20 48 -20 48<br />

Pressure switch cut-out pressure (bar) 11 -<br />

Valve cut-out pressure (bar) 12.5 12.5<br />

Test pressure, unit leak test (bar) 10<br />

Check all items against shipping list. Immediately notify the<br />

nearest <strong>Carrier</strong> representative if any item is missing.<br />

To prevent loss or damage (standard EN 378-2 11.22 k, annex<br />

A and B), leave all parts in original packages until beginning<br />

installation. All openings are closed with covers or plugs to<br />

prevent dirt and debris from entering machine components<br />

during shipping. A full operating oil charge is placed in the<br />

oil sump before shipment.<br />

3.2.2 - Provide machine protection<br />

Protect machine and starter from construction dirt and moisture.<br />

Keep protective shipping covers in place until machine is ready<br />

for installation.<br />

Do not keep the <strong>19XR</strong> units outside where they are exposed to<br />

the weather, as the sensitive control mechanism and the<br />

electronic modules may be damaged.<br />

The unit must be checked periodically during its whole<br />

operating life to ensure that no shocks (handling accessories,<br />

tools etc.) have damaged it. If necessary, the damaged parts<br />

must be repaired or replaced. See also chapter “Maintenance”.<br />

If machine is exposed to freezing temperatures after water<br />

circuits have been installed, open waterbox drains and remove<br />

all water from cooler and condenser. Leave drains open until<br />

system is filled.<br />

3.3 - Rigging the Machine<br />

The <strong>19XR</strong> machine can be rigged as an entire assembly. It also<br />

has flanged connections that allow the compressor, cooler, and<br />

condenser sections to be separated and rigged individually.<br />

3.3.1 - Rigging the complete machine<br />

See rigging instructions on label attached to machine. Also refer<br />

to physical data and Tables 1-7 (chapter 3.3.3). Lift machine<br />

only from the points indicated in the instructions supplied and<br />

in the machine rigging drawings. Each lifting cable or chain<br />

must be capable of supporting the entire weight of the machine.<br />

WARNING: Lifting machine from points other than those<br />

specified may result in serious damage to the unit and personal<br />

injury. Rigging equipment and procedures must be adequate<br />

for machine weight. See Tables 1-7 (chapter 3.3.3) for<br />

machine weights.<br />

NOTE: These weights are broken down into component<br />

sections for use when installing the unit in sections. For the<br />

complete machine weight, add all component sections and<br />

refrigerant charge together. See Tables 1-7 (chapter 3.3.3) for<br />

machine component weights.<br />

IMPORTANT: Make sure that rigging cable is over the rigging<br />

bar before lifting.<br />

17