19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.6.4 - Make the necessary connections for the outgoing<br />

control signals<br />

Connect the auxiliary equipment, the chilled water pumps and<br />

the condenser water pumps, as well as the additional alarms, as<br />

indicated in the job wiring diagrams.<br />

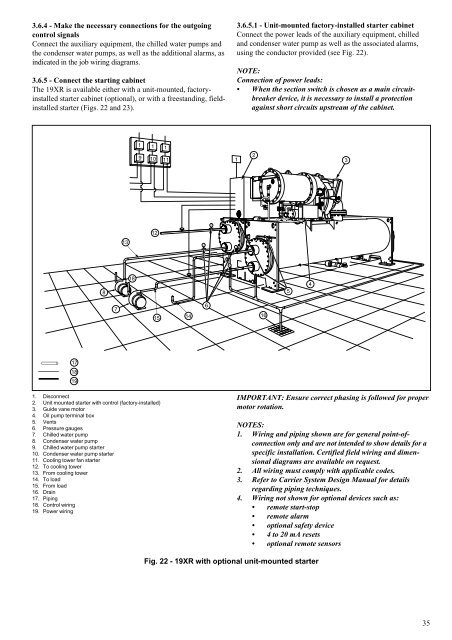

3.6.5 - Connect the starting cabinet<br />

The <strong>19XR</strong> is available either with a unit-mounted, factoryinstalled<br />

starter cabinet (optional), or with a freestanding, fieldinstalled<br />

starter (Figs. 22 and 23).<br />

17<br />

18<br />

19<br />

1. Disconnect<br />

2. Unit mounted starter with control (factory-installed)<br />

3. Guide vane motor<br />

4. Oil pump terminal box<br />

5. Vents<br />

6. Pressure gauges<br />

7. Chilled water pump<br />

8. Condenser water pump<br />

9. Chilled water pump starter<br />

10. Condenser water pump starter<br />

11. Cooling tower fan starter<br />

12. To cooling tower<br />

13. From cooling tower<br />

14. To load<br />

15. From load<br />

16. Drain<br />

17. Piping<br />

18. Control wiring<br />

19. Power wiring<br />

8<br />

7<br />

13<br />

18<br />

12<br />

15<br />

14<br />

Fig. 22 - <strong>19XR</strong> with optional unit-mounted starter<br />

3.6.5.1 - Unit-mounted factory-installed starter cabinet<br />

Connect the power leads of the auxiliary equipment, chilled<br />

and condenser water pump as well as the associated alarms,<br />

using the conductor provided (see Fig. 22).<br />

NOTE:<br />

Connection of power leads:<br />

When the section switch is chosen as a main circuitbreaker<br />

device, it is necessary to install a protection<br />

against short circuits upstream of the cabinet.<br />

16<br />

IMPORTANT: Ensure correct phasing is followed for proper<br />

motor rotation.<br />

NOTES:<br />

1. Wiring and piping shown are for general point-ofconnection<br />

only and are not intended to show details for a<br />

specific installation. Certified field wiring and dimensional<br />

diagrams are available on request.<br />

2. All wiring must comply with applicable codes.<br />

3. Refer to <strong>Carrier</strong> System Design Manual for details<br />

regarding piping techniques.<br />

4. Wiring not shown for optional devices such as:<br />

remote start-stop<br />

remote alarm<br />

optional safety device<br />

4 to 20 mA resets<br />

optional remote sensors<br />

3<br />

35