19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

To pressurize with dry nitrogen<br />

Another method of leak testing is to pressurize with nitrogen<br />

only and to use a soap bubble solution or an ultrasonic leak<br />

detector to determine if leaks are present. This should only be<br />

done if all refrigerant has been evacuated from the vessel.<br />

1. Connect a copper tube from the pressure regulator on the<br />

cylinder to the refrigerant charging valve.<br />

2. Never apply full cylinder pressure to the pressurizing line.<br />

Follow the listed sequence.<br />

3. Open the charging valve fully.<br />

4. Slowly open the cylinder regulating valve.<br />

5. Observe the pressure gauge on the chiller and close the<br />

regulating valve when the pressure reaches test level. Do<br />

not exceed 965 kPa.<br />

6. Close the charging valve on the chiller. Remove the<br />

copper tube if no longer required.<br />

Repair the leak, retest and apply standing vacuum test<br />

After pressurizing the chiller, test for leaks with an electronic<br />

leak detector, soap bubble solution, or an ultrasonic leak<br />

detector. Bring the chiller back to atmospheric pressure, repair<br />

any leaks found, and retest.<br />

After retesting and finding no leaks, apply a standing vacuum<br />

test, and then dehydrate the chiller. Refer to the Standing<br />

Vacuum Test and Chiller Dehydration in the Before Initial<br />

Start-Up section.<br />

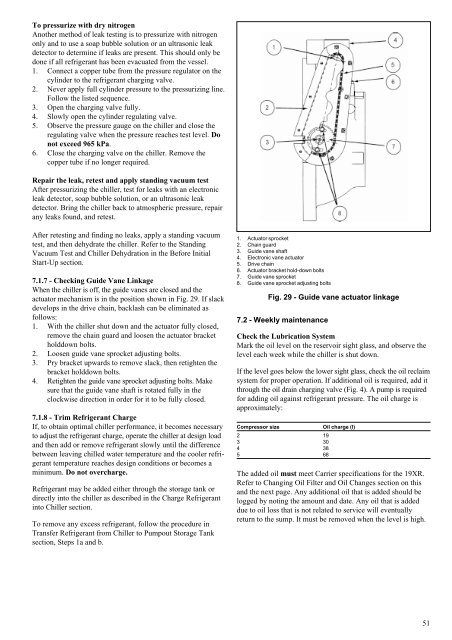

7.1.7 - Checking Guide Vane Linkage<br />

When the chiller is off, the guide vanes are closed and the<br />

actuator mechanism is in the position shown in Fig. 29. If slack<br />

develops in the drive chain, backlash can be eliminated as<br />

follows:<br />

1. With the chiller shut down and the actuator fully closed,<br />

remove the chain guard and loosen the actuator bracket<br />

holddown bolts.<br />

2. Loosen guide vane sprocket adjusting bolts.<br />

3. Pry bracket upwards to remove slack, then retighten the<br />

bracket holddown bolts.<br />

4. Retighten the guide vane sprocket adjusting bolts. Make<br />

sure that the guide vane shaft is rotated fully in the<br />

clockwise direction in order for it to be fully closed.<br />

7.1.8 - Trim Refrigerant Charge<br />

If, to obtain optimal chiller performance, it becomes necessary<br />

to adjust the refrigerant charge, operate the chiller at design load<br />

and then add or remove refrigerant slowly until the difference<br />

between leaving chilled water temperature and the cooler refrigerant<br />

temperature reaches design conditions or becomes a<br />

minimum. Do not overcharge.<br />

Refrigerant may be added either through the storage tank or<br />

directly into the chiller as described in the Charge Refrigerant<br />

into Chiller section.<br />

To remove any excess refrigerant, follow the procedure in<br />

Transfer Refrigerant from Chiller to Pumpout Storage Tank<br />

section, Steps 1a and b.<br />

1. Actuator sprocket<br />

2. Chain guard<br />

3. Guide vane shaft<br />

4. Electronic vane actuator<br />

5. Drive chain<br />

6. Actuator bracket hold-down bolts<br />

7. Guide vane sprocket<br />

8. Guide vane sprocket adjusting bolts<br />

Fig. 29 - Guide vane actuator linkage<br />

7.2 - Weekly maintenance<br />

Check the Lubrication System<br />

Mark the oil level on the reservoir sight glass, and observe the<br />

level each week while the chiller is shut down.<br />

If the level goes below the lower sight glass, check the oil reclaim<br />

system for proper operation. If additional oil is required, add it<br />

through the oil drain charging valve (Fig. 4). A pump is required<br />

for adding oil against refrigerant pressure. The oil charge is<br />

approximately:<br />

Compressor size Oil charge (l)<br />

2 19<br />

3 30<br />

4 38<br />

5 68<br />

The added oil must meet <strong>Carrier</strong> specifications for the <strong>19XR</strong>.<br />

Refer to Changing Oil Filter and Oil Changes section on this<br />

and the next page. Any additional oil that is added should be<br />

logged by noting the amount and date. Any oil that is added<br />

due to oil loss that is not related to service will eventually<br />

return to the sump. It must be removed when the level is high.<br />

51