19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5 - INITIAL START-UP<br />

5.1 - Preparation<br />

Before starting the chiller, check that the:<br />

1. Power is on to the main starter, oil pump relay, tower fan<br />

starter, oil heater relay, and the chiller control centre.<br />

2. Cooling tower water is at proper level and at or below<br />

design entering temperature.<br />

3. Chiller is charged with refrigerant and all refrigerant and<br />

oil valves are in their proper operating position.<br />

4. Oil is at the proper level in the reservoir sight glasses.<br />

5. Oil reservoir temperature is above 60°C or refrigerant<br />

temperature plus 28°C.<br />

6. Valves in the evaporator and condenser water circuits are<br />

open. NOTE: If pumps are not automatic, make sure water<br />

is circulating properly.<br />

NOTE: If the pumps are not automatic, check that the water<br />

is circulating correctly.<br />

WARNING: Do not permit water or brine that is warmer than<br />

52°C to flow through the cooler or condenser. Refrigerant<br />

overpressure may discharge through the relief devices and<br />

result in the loss of refrigerant charge.<br />

7. 'Control test' screen access<br />

At the control screen press the scroll keys to access the<br />

start-up menu option (Terminate lockout option).<br />

46<br />

Press the selection that permits chiller start-up and answer<br />

'YES' to restart it in operating mode. The unit is locked at<br />

the factory to prevent accidental start-up.<br />

5.2 - Dry Run to Test Start-Up Sequence<br />

1. Disengage the main motor disconnect (QF101 for the<br />

factory-mounted starter) on the starter front panel. This<br />

should only disconnect the motor power. Power to the<br />

controls, oil pump, and starter control circuit should still<br />

be energized.<br />

2. Look at the default screen on the local interface: the Status<br />

message in the upper left-hand corner will read, “Manually<br />

Stopped’’. Press CCN or Local to start. If the chiller controls<br />

do not go into a start mode, go to the Schedule screen and<br />

override the schedule or change the occupied time. Press the<br />

LOCAL softkey to begin the start-up sequences.<br />

3. Check that chilled water and condenser water pumps<br />

energize.<br />

4. Check that the oil pump starts and pressurizes the lubrication<br />

system. After the oil pump has run about 45 seconds,<br />

the starter will be energized and go through its start-up<br />

sequence.<br />

5. Check the main contactor for proper operation.<br />

6. The <strong>PIC</strong> <strong>II</strong> will eventually show an alarm for motor amps<br />

not sensed. Reset this alarm and continue with the initial<br />

start-up.<br />

5.3 - Check Rotation<br />

1. Engage the main motor disconnect on the front of the<br />

starter panel. The motor is now ready for rotation check.<br />

2. After the default screen Status message states “Ready for<br />

Start’’ press the LOCAL softkey; start-up checks will be<br />

made by the control.<br />

3. When the starter is energized and the motor begins to<br />

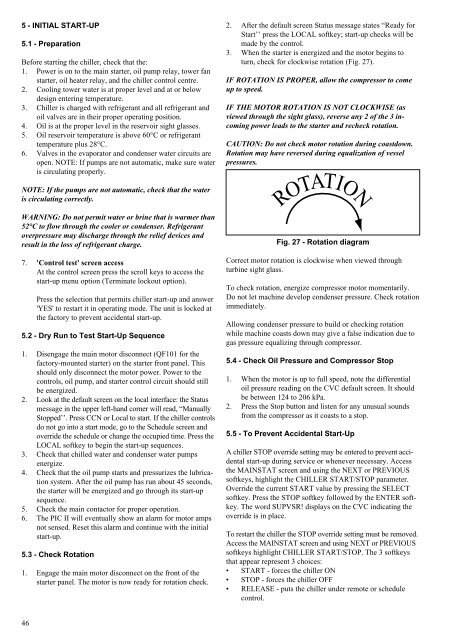

turn, check for clockwise rotation (Fig. 27).<br />

IF ROTATION IS PROPER, allow the compressor to come<br />

up to speed.<br />

IF THE MOTOR ROTATION IS NOT CLOCKWISE (as<br />

viewed through the sight glass), reverse any 2 of the 3 incoming<br />

power leads to the starter and recheck rotation.<br />

CAUTION: Do not check motor rotation during coastdown.<br />

Rotation may have reversed during equalization of vessel<br />

pressures.<br />

ROTATION<br />

Fig. 27 - Rotation diagram<br />

Correct motor rotation is clockwise when viewed through<br />

turbine sight glass.<br />

To check rotation, energize compressor motor momentarily.<br />

Do not let machine develop condenser pressure. Check rotation<br />

immediately.<br />

Allowing condenser pressure to build or checking rotation<br />

while machine coasts down may give a false indication due to<br />

gas pressure equalizing through compressor.<br />

5.4 - Check Oil Pressure and Compressor Stop<br />

1. When the motor is up to full speed, note the differential<br />

oil pressure reading on the CVC default screen. It should<br />

be between 124 to 206 kPa.<br />

2. Press the Stop button and listen for any unusual sounds<br />

from the compressor as it coasts to a stop.<br />

5.5 - To Prevent Accidental Start-Up<br />

A chiller STOP override setting may be entered to prevent accidental<br />

start-up during service or whenever necessary. Access<br />

the MAINSTAT screen and using the NEXT or PREVIOUS<br />

softkeys, highlight the CHILLER START/STOP parameter.<br />

Override the current START value by pressing the SELECT<br />

softkey. Press the STOP softkey followed by the ENTER softkey.<br />

The word SUPVSR! displays on the CVC indicating the<br />

override is in place.<br />

To restart the chiller the STOP override setting must be removed.<br />

Access the MAINSTAT screen and using NEXT or PREVIOUS<br />

softkeys highlight CHILLER START/STOP. The 3 softkeys<br />

that appear represent 3 choices:<br />

START - forces the chiller ON<br />

STOP - forces the chiller OFF<br />

RELEASE - puts the chiller under remote or schedule<br />

control.