19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The valve is opened counter-clockwise, and closed clockwise.<br />

4.14 - <strong>19XR</strong> chiller equalization with pumpout unit<br />

The following procedure describes how to equalize refrigerant<br />

pressure on an isolated <strong>19XR</strong> chiller using the pumpout unit:<br />

1. Access the TERMINATE LOCKOUT mode in the<br />

Control Test.<br />

2. Turn on the chilled water and condenser water pumps to<br />

prevent possible freezing.<br />

3. Open valve 4 on the pumpout unit and open valves 1a and<br />

1b on the chiller cooler and condenser, Fig. 18 and 19.<br />

Slowly open valve 2 on the pumpout unit to equalize the<br />

pressure. This process will take approximately 15 minutes.<br />

4. Once the pressures have equalized, the discharge isolation<br />

valve, cooler isolation valve, optional hot gas bypass isolation<br />

valve, and the refrigerant isolation valve can be opened.<br />

Close valves 1a and 1b, and all pumpout unit valves.<br />

The full refrigerant charge on the <strong>19XR</strong> will vary with chiller<br />

components and design conditions, indicated on the job data<br />

specifications. An approximate charge may be found by adding<br />

the condenser charge to the cooler charge listed in Table 7.<br />

Always operate the condenser and chilled water pumps during<br />

charging operations to prevent freeze-ups. Use the Control Test<br />

Terminate Lockout to monitor conditions and start the pumps.<br />

If the chiller has been shipped with a holding charge, the<br />

refrigerant will be added through the refrigerant charging valve<br />

(Fig. 18 and 19, valve 7) or to the pumpout charging connection.<br />

First evacuate the nitrogen holding charge from the chiller<br />

vessels. Charge the refrigerant as a gas until the system pressure<br />

exceeds 141 kPa for HFC-134a. After the chiller is beyond this<br />

pressure the refrigerant should be charged as a liquid until all<br />

the recommended refrigerant charge has been added.<br />

4.15 Trimming refrigerant charge<br />

The <strong>19XR</strong> is shipped with the correct charge for the design duty<br />

of the chiller. Trimming the charge can best be accomplished<br />

when design load is available. To trim, check the temperature<br />

difference between leaving chilled water temperature and<br />

cooler refrigerant temperature at full load design conditions. If<br />

necessary, add or remove refrigerant to bring the temperature<br />

difference to design conditions or minimum differential. If the<br />

unit incorporates a sight glass (option) and has a full charge,<br />

bubbling must take place in the upper level of the vessel.<br />

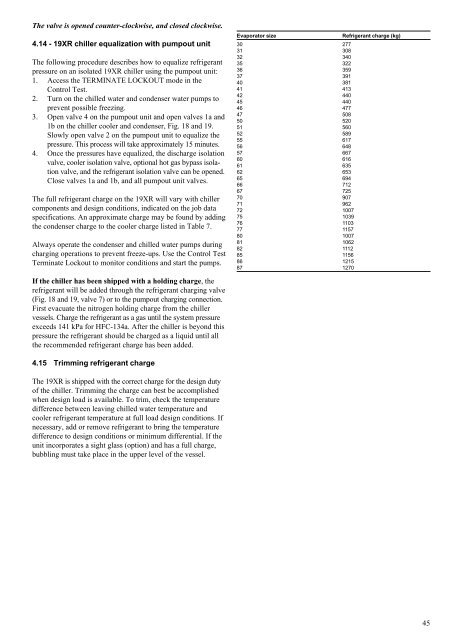

Evaporator size Refrigerant charge (kg)<br />

30 277<br />

31 308<br />

32 340<br />

35 322<br />

36 359<br />

37 391<br />

40 381<br />

41 413<br />

42 440<br />

45 440<br />

46 477<br />

47 <strong>50</strong>8<br />

<strong>50</strong> 520<br />

51 560<br />

52 589<br />

55 617<br />

56 648<br />

57 667<br />

60 616<br />

61 635<br />

62 653<br />

65 694<br />

66 712<br />

67 725<br />

70 907<br />

71 962<br />

72 1007<br />

75 1039<br />

76 1103<br />

77 1157<br />

80 1007<br />

81 1062<br />

82 1112<br />

85 1156<br />

86 1215<br />

87 1270<br />

45