19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

19XR (PIC II) Hermetic Centrifugal Liquid Chillers 50 Hz - Carrier

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

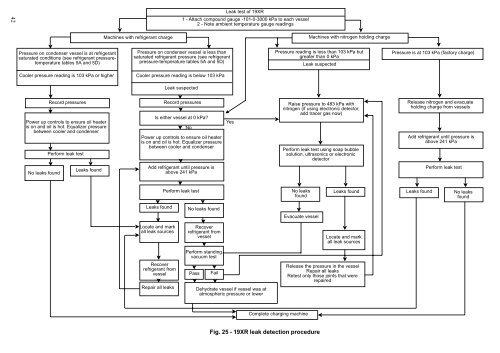

42<br />

Pressure on condenser vessel is at refrigerant<br />

saturated conditions (see refrigerant pressuretemperature<br />

tables 5A and 5D)<br />

Cooler pressure reading is 103 kPa or higher<br />

Record pressures<br />

Power up controls to ensure oil heater<br />

is on and oil is hot. Equalizer pressure<br />

between cooler and condenser<br />

No leaks found<br />

Perform leak test<br />

Leaks found<br />

Machines with refrigerant charge<br />

Leak test of <strong>19XR</strong><br />

1 - Attach compound gauge -101-0-3000 kPa to each vessel<br />

2 - Note ambient temperature gauge readings<br />

Pressure on condenser vessel is less than<br />

saturated refrigerant pressure (see refrigerant<br />

pressure-temperature tables 5A and 5D)<br />

Cooler pressure reading is below 103 kPa<br />

Leak suspected<br />

Record pressures<br />

Is either vessel at 0 kPa?<br />

Power up controls to ensure oil heater<br />

is on and oil is hot. Equalizer pressure<br />

between cooler and condenser<br />

Add refrigerant until pressure is<br />

above 241 kPa<br />

Leaks found<br />

Locate and mark<br />

all leak sources<br />

Recover<br />

refrigerant from<br />

vessel<br />

Repair all leaks<br />

No<br />

Perform leak test<br />

No leaks found<br />

Recover<br />

refrigerant from<br />

vessel<br />

Perform standing<br />

vacuum test<br />

Pass<br />

Fail<br />

Yes<br />

Dehydrate vessel if vessel was at<br />

atmospheric pressure or lower<br />

Fig. 25 - <strong>19XR</strong> leak detection procedure<br />

Machines with nitrogen holding charge<br />

Pressure reading is less than 103 kPa but<br />

greater than 0 kPa<br />

Leak suspected<br />

Raise pressure to 483 kPa with<br />

nitrogen (if using electronic detector,<br />

add tracer gas now)<br />

Perform leak test using soap bubble<br />

solution, ultrasonics or electronic<br />

detector<br />

No leaks<br />

found<br />

Evacuate vessel<br />

Complete charging machine<br />

Leaks found<br />

Locate and mark<br />

all leak sources<br />

Release the pressure in the vessel<br />

Repair all leaks<br />

Retest only those joints that were<br />

repaired<br />

Pressure is at 103 kPa (factory charge)<br />

Release nitrogen and evacuate<br />

holding charge from vessels<br />

Add refrigerant until pressure is<br />

above 241 kPa<br />

Perform leak test<br />

Leaks found No leaks<br />

found