- Page 1 and 2: " "! %&''( )*

- Page 4 and 5: ! " # $ % &

- Page 6 and 7: $* +%#, The author wish to express

- Page 8 and 9: 2.3 Effect of alloying elements on

- Page 10 and 11: 4 C H A P T E R 4 73 # $%&' 4.1 In

- Page 12 and 13: 6.2.3.2 Open circuit potential vs.

- Page 14 and 15: eprocessing can be recovered, and c

- Page 16 and 17: The ex-situ study of passive film w

- Page 18 and 19: Fig.3.10: Schematic of electrical e

- Page 20 and 21: Fig.6.11: Polarization study of unc

- Page 22 and 23: AISI: American Institute of Steel I

- Page 24 and 25: Chapter 1 C H A P T E R 1 Spent Nuc

- Page 26 and 27: Chapter 1 1.3 Challenges in spent n

- Page 28 and 29: Chapter 1 corrosion resistance. The

- Page 30 and 31: Chapter 1 choice of zirconium is du

- Page 32 and 33: C H A P T E R2

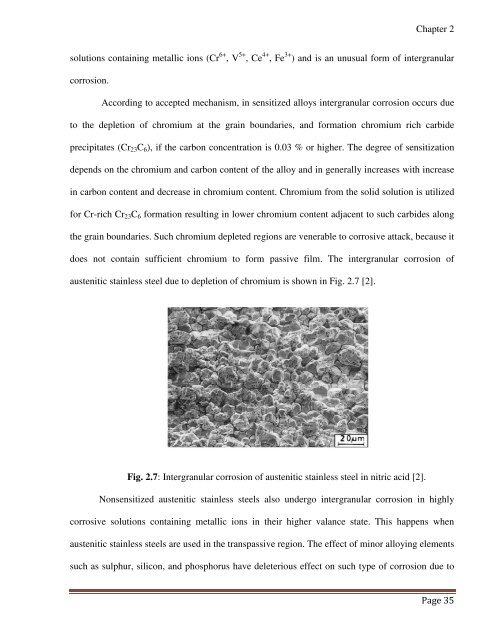

- Page 34 and 35: Chapter 2 temperature, (c) higher i

- Page 36 and 37: Chapter 2 Chromium in excess of 12

- Page 38 and 39: Chapter 2 2. 3 Effect of alloying e

- Page 40 and 41: Chapter 2 The twins are identified

- Page 42 and 43: Chapter 2 and at temperature around

- Page 44 and 45: Chapter 2 of adsorption of oxygen o

- Page 46 and 47: Chapter 2 transpassive dissolution

- Page 50 and 51: Chapter 2 their segregation to the

- Page 52 and 53: Chapter 2 is intimately related to

- Page 54 and 55: Chapter 2 in nature because the dis

- Page 56 and 57: C H A P T E R3

- Page 58 and 59: Chapter 3 3.1.1.2 Specimen preparat

- Page 60 and 61: Chapter 3 ionized. However, differe

- Page 62 and 63: Chapter 3 various industrial applic

- Page 64 and 65: Chapter 3 In the present investigat

- Page 66 and 67: Chapter 3 3.1.3.2 Atomic force micr

- Page 68 and 69: Chapter 3 present on the surface fo

- Page 70 and 71: Chapter 3 necessary condition is th

- Page 72 and 73: Chapter 3 Y m is the sputter yield.

- Page 74 and 75: Chapter 3 Fig. 3.7: Schematic of X-

- Page 76 and 77: Chapter 3 rate of 10Å/min using 5

- Page 78 and 79: Chapter 3 different doses of nitrog

- Page 80 and 81: Chapter 3 The modulus of electroche

- Page 82 and 83: Chapter 3 equivalent circuit as sho

- Page 84 and 85: Chapter 3 reference electrode with

- Page 86 and 87: Chapter 3 for understanding the pas

- Page 88 and 89: C H A P T E R4

- Page 90 and 91: Chapter 4 encountered by all materi

- Page 92 and 93: Chapter 4 pitting, and intergranula

- Page 94 and 95: Chapter 4 The ridged structure, and

- Page 96 and 97: Chapter 4 nitric acid is that the b

- Page 98 and 99:

Chapter 4 Potential (V) Vs Ag/AgCl

- Page 100 and 101:

Chapter 4 4.2.3 In-situ electrochem

- Page 102 and 103:

Chapter 4 The surface morphologies

- Page 104 and 105:

Chapter 4 a b c d Opening up of gra

- Page 106 and 107:

Chapter 4 Intensity (Arbitrary unit

- Page 108 and 109:

Chapter 4 The chromium, and oxygen

- Page 110 and 111:

Chapter 4 Intensity (Arbitrary unit

- Page 112 and 113:

C H A P T E R5

- Page 114 and 115:

Chapter 5 elements, and often impar

- Page 116 and 117:

Chapter 5 5.2 Results and discussi

- Page 118 and 119:

Chapter 5 Presence of oxygen is due

- Page 120 and 121:

Chapter 5 was an increase in marten

- Page 122 and 123:

Chapter 5 formation of Cr 2 N was a

- Page 124 and 125:

Chapter 5 electrochemical environme

- Page 126 and 127:

Chapter 5 N + Dose E corr (mV vs. A

- Page 128 and 129:

Chapter 5 layer capacitance (C dl )

- Page 130 and 131:

Chapter 5 correlation between surfa

- Page 132 and 133:

Chapter 5 boundary dissolution was

- Page 134 and 135:

Chapter 6 C H A P T E R 6

- Page 136 and 137:

Chapter 6 193]. As a single phase c

- Page 138 and 139:

Chapter 6 particles range from 8×1

- Page 140 and 141:

Chapter 6 Results revealed that in

- Page 142 and 143:

Chapter 6 The change over from capa

- Page 144 and 145:

Chapter 6 The impedance parameters

- Page 146 and 147:

Chapter 6 Conc. Substrate condition

- Page 148 and 149:

Chapter 6 6.6a-d. The uncoated spec

- Page 150 and 151:

Chapter 6 (55.18°) respectively, w

- Page 152 and 153:

Chapter 6 OCP shifted in noble dire

- Page 154 and 155:

Chapter 6 The high phase angle over

- Page 156 and 157:

Chapter 6 Fig. 6.10d: Log f vs. Log

- Page 158 and 159:

Chapter 6 Fig. 6.11b: Polarization

- Page 160 and 161:

Chapter 6 Covalent aspect of lattic

- Page 162 and 163:

Chapter 6 As compared to uncoated s

- Page 164 and 165:

Chapter 6 6.2.3.2 Open circuit pote

- Page 166 and 167:

Chapter 6 Similarly, the plots for

- Page 168 and 169:

Chapter 6 for the duplex coating, a

- Page 170 and 171:

Chapter 6 Fig.6.16b: Polarization s

- Page 172 and 173:

Chapter 6 6.2.3.5 Morphological exa

- Page 174 and 175:

Chapter 7 C H A P T E R 7 The cha

- Page 176 and 177:

Chapter 7 1. Surface morphology exa

- Page 178 and 179:

Chapter 7 6 Duplex Ti-TiO 2 coated

- Page 180 and 181:

Chapter 7 EC-SPM study on effect

- Page 183 and 184:

[1] Baldev Raj, U. Kamachi Mudali,

- Page 185 and 186:

[37] G. Okamoto, T. Shibata, Corros

- Page 187 and 188:

[79] M. Moens, M. Van Craen, F.C. A

- Page 189 and 190:

[117] R.E.Williford, C.F.Windisch J

- Page 191 and 192:

[157] N. Mottu, M. Vayer, R. Erre,

- Page 193:

[197] M. Metikos Hukovic, M. Ceraj

- Page 196 and 197:

[19] H. H. Uhlig, Corros Sci, 19 (1

- Page 198 and 199:

[57] J. F. Ziegler, J. P. Biersack,

- Page 200 and 201:

[97] I. Betova, M. Bojinov, V. Kara

- Page 202 and 203:

[139] V. Ashworth, R. P. M. Procter

- Page 204 and 205:

[176] G. Frankel, G. Grundmeier, H.

- Page 207 and 208:

List of publications 1. Referred