Wüest M. 51 Wykes M. 82 Yamaguchi M. 17 Ybarra G. 129 Yubero F ...

Wüest M. 51 Wykes M. 82 Yamaguchi M. 17 Ybarra G. 129 Yubero F ...

Wüest M. 51 Wykes M. 82 Yamaguchi M. 17 Ybarra G. 129 Yubero F ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

JUNE 28 WEDNESDAY MORNING<br />

JS2-WeM-INV.2 TRIBOLOGICAL CHARACTERIZATION OF METAL CAR-<br />

BIDE/AMORPHOUS CARBON NANOCOMPOSITES: FROM MACRO TO THE MICRO-<br />

SCALE. J.C. Sánchez-López*, D. Martínez-Martínez, C. López-Cartes, A. Fernández. Instituto de<br />

Ciencia de Materiales de Sevilla, CSIC-Universidad de Sevilla, Avda. Américo Vespucio 49, 41092-<br />

Sevilla, Spain. *E-mail: jcslopez@icmse.csic.es<br />

The design of multilayered and nanocomposite coatings structures have allowed to achieve superior<br />

hardness, toughness and excellent wear resistance useful for many industrial applications. The optimization<br />

of the tribological performance of such materials represents a challenge as depends not only<br />

on factors intrinsic to the coatings (chemical composition, microstructure, phase composition, texture…)<br />

but, besides, others related to the application conditions (adhesion to the substrate, nature of<br />

the counterfaces, environment, load, etc.). In this work, we review the results obtained for nanocomposite<br />

coatings made of nanocrystalline metal carbides and amorphous carbon (a-C) prepared by<br />

PVD techniques. Their characterization appears complicated mainly due to the lack of long-range<br />

order and the heterogeneity in chemical compositions at the nanometric scale. The nanocrystalline/amorphous<br />

ratio appears to be a key-parameter to control the tribological properties and its<br />

quantification results always not easy. Focusing mainly in the TiC/a-C system prepared by magnetron<br />

sputtering as example, it is showed how the investigation of chemical and structural features at<br />

the micro-scale help to determine the aspects influencing the tribological performance at the macroscale.<br />

By varying the power applied to each target (titanium or graphite), it was possible to prepare a<br />

wide family of film structures covering from a quasi-polycrystalline TiC to a nanocomposite formed<br />

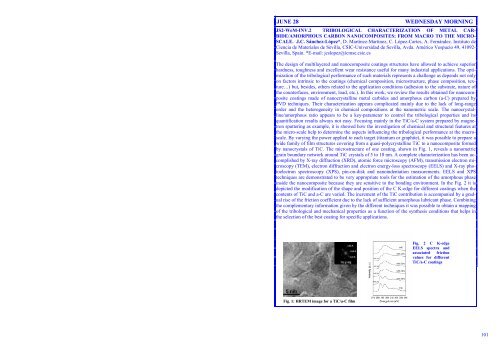

by nanocrystals of TiC. The microstructure of one coating, shown in Fig. 1, reveals a nanometric<br />

grain boundary network around TiC crystals of 5 to 10 nm. A complete characterization has been accomplished<br />

by X-ray diffraction (XRD), atomic force microscopy (AFM), transmission electron microscopy<br />

(TEM), electron diffraction and electron energy-loss spectroscopy (EELS) and X-ray photoelectron<br />

spectroscopy (XPS), pin-on-disk and nanoindentation measurements. EELS and XPS<br />

techniques are demonstrated to be very appropriate tools for the estimation of the amorphous phase<br />

inside the nanocomposite because they are sensitive to the bonding environment. In the Fig. 2 it is<br />

depicted the modification of the shape and position of the C K-edge for different coatings when the<br />

contents of TiC and a-C are varied. The increment of the TiC contribution is accompanied by a gradual<br />

rise of the friction coefficient due to the lack of sufficient amorphous lubricant phase. Combining<br />

the complementary information given by the different techniques it was possible to obtain a mapping<br />

of the tribological and mechanical properties as a function of the synthesis conditions that helps in<br />

the selection of the best coating for specific applications.<br />

Fig. 2 C K-edge<br />

EELS spectra and<br />

associated friction<br />

values for different<br />

TiC/a-C coatings<br />

Fig. 1: HRTEM image for a TiC/a-C film<br />

101