English version - Hexagon Composites ASA

English version - Hexagon Composites ASA

English version - Hexagon Composites ASA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

COMROD COMMUNICATION <strong>ASA</strong> – LISTING ON THE OSLO STOCK EXCHANGE<br />

5.8.1 Quality control and testing<br />

The Company is recognized for its high quality products. The Company’s subsidiary Comrod AS, is<br />

ISO 9001-2000 certified for its design, development, manufacturing and marketing processes. The<br />

Company’s French subsidiary, Lerc SA, is in the process of implementing a quality policy equivalent<br />

to ISO 9001. The Company’s insulating products have been certified in accordance with EU standards.<br />

The Company’s products have been designed to withstand extreme conditions and must withstand<br />

extensive tests to ensure that the quality standards are being met.<br />

The products go through extensive testing in the Company’s on site test laboratories in Norway and<br />

France. Testing include chemical, mechanical, electrical and climatic testing.<br />

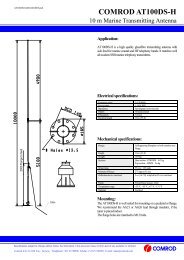

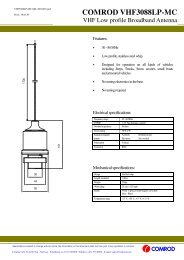

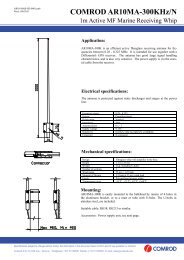

The manufacturing and technical platform is based on substantial development and experience within<br />

composites and antenna and mast manufacturing to ensure the best possible performance of the<br />

Company’s communication masts and antennas. All vital antenna components are completely<br />

protected from the elements. The antenna conductors are encapsulated in polyurethane foam, which<br />

keeps out humidity which again prevents corrosion and ensures that the conductor lies stable in the<br />

antenna sheath. The foam prevents fractures due to vibrations from engines and also enhances<br />

mechanical stability. The Howald production method 3 using fibreglass reinforced epoxy, provides the<br />

unique strength and flexibility. To achieve the optimal quality on the antenna surface, all tubes go<br />

through a grinding process before a strong two component, elastic polyurethane coating is applied. As<br />

a result salt and dirt cannot adhere, reducing the danger of sparkover and the antenna is effectively<br />

protected against water, ice and damaging UV radiation.<br />

All products are subject to extensive testing. Comrod uses the standards listed below.<br />

- MIL-STD-810F<br />

- MIL-STD-461E<br />

- MIL-STD-464<br />

- MIL-HDBK-454A<br />

- MIL-HDBK-217F<br />

- DEF-STAN 00-35<br />

- IEC 60945<br />

- IEC 60060-2<br />

- IEC 60068-2<br />

- ANSI TIA/EIA-222-F<br />

These are all well known international standards for defence and shipbourne equipment.<br />

5.9 Property, plant and equipment<br />

In Norway the Company owns a manufacturing plant at Tau, 45 minutes’ travel with ferry outside<br />

Stavanger. The plant covers about 2,771 square meters (m 2 ) and have today an approximate book<br />

value of about MNOK 11, and the insurance value is MNOK 39.<br />

The plant has been built and upgraded in the following seven steps:<br />

- 1970: New factory existing of 700m 2 production site and a 230m 2 office building.<br />

- 1972: Extension of the production site with 800m 2 included shelter.<br />

- 1982: New warehouse 201m 2<br />

- 1989: Second level on the office building 230m 2 .<br />

- 1996: Rebuilding the production plant and a new 360m 2 mechanical production compartment.<br />

- 2002: New paint compartment 300m 2 .<br />

3 The Howald production method involves winding/spinning glass fibre onto a mandrill.<br />

43