Pharmaceutical Technology: Controlled Drug Release, Volume 2

Pharmaceutical Technology: Controlled Drug Release, Volume 2

Pharmaceutical Technology: Controlled Drug Release, Volume 2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

62 MATRIX FORMULATIONS [CH. 5<br />

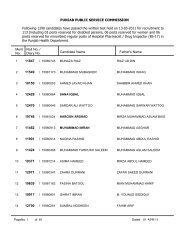

Fig. 1—Flow function and flowability (ic) of the optimized formulations.<br />

The porosimetry measurements<br />

In order to characterize the microstructure of the matrices, the total porosimetry factor, the pore<br />

volume, the pore surface and the mean pore diameter were measured using a mercury porosimeter<br />

(Micrometrics) [3]. The mean of three replicates and their coefficient of variation are indicated in<br />

Table 3.<br />

From the results, it is possible to draw the following conclusions.<br />

(1) In accordance with the Dubinin classification [14], all the matrix tablets exhibited macropores<br />

(mean pore diameter >200Å).<br />

(2) The tablets obtained by direct compression in a single punch machine (Frogerais) and those<br />

obtained by wet granulation had very similar values; only the coefficient of variation<br />

differentiate these two processes.<br />

(3) As expected, as the applied UPF increased, the porosimetry parameters decreased (UPF<br />

values: direct compression and wet granulation, 7 kN; double compression, 12 kN; separate<br />

compaction, 19 kN; compaction of the mixture, 31 kN).<br />

(4) The variability of the porosity parameters may be used to differentiate the processes. It also<br />

explains the variability of the dissolution parameters because of the same order of variation<br />

(CV):<br />

wet granulation (3.0)