Chapter 3 Decision Support Model (IUWS-DSM) - Tubdok

Chapter 3 Decision Support Model (IUWS-DSM) - Tubdok

Chapter 3 Decision Support Model (IUWS-DSM) - Tubdok

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Chapter</strong> 3 · <strong>Decision</strong> <strong>Support</strong> <strong>Model</strong> (<strong>IUWS</strong>-<strong>DSM</strong>) 77<br />

based only on pipe diameter and length. Thereby, the <strong>IUWS</strong>-<strong>DSM</strong> excludes the factor of<br />

population density, too.<br />

Pump stations are the essential parts of the conveying system, so the empirical cost<br />

functions are developed in general. Other ancillary works such as storages, valves and<br />

hydrants, etc., are often estimated approximately as the percentage of the pipe costs.<br />

Certainly, the costs of those ancillary works can be estimated by empirical cost function, as<br />

well (e.g. USEPA 1999 and Burnside 2005).<br />

The same methods are used to estimating O&M costs of conveying system, i.e. with cost<br />

functions or as percentage of construction cost. Oron (1996) states that annually O&M costs<br />

of distribution system are usually up to 3,0% of the overall capital investment over the lifetime<br />

of the asset, and Tang et al. (2006) calculated O&M costs of the water reuse system in Hong<br />

Kong to be 1,03% of the capital cost. The general O&M cost is thereby suggested as 2,0% of<br />

the capital cost (Chugg 2007).<br />

3.4.3 Energy assessment<br />

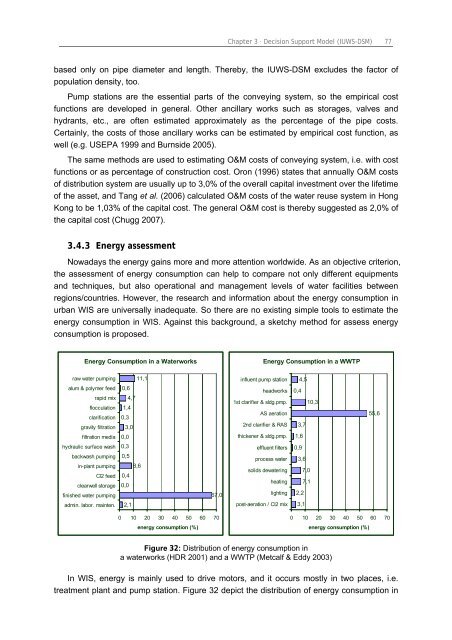

Nowadays the energy gains more and more attention worldwide. As an objective criterion,<br />

the assessment of energy consumption can help to compare not only different equipments<br />

and techniques, but also operational and management levels of water facilities between<br />

regions/countries. However, the research and information about the energy consumption in<br />

urban WIS are universally inadequate. So there are no existing simple tools to estimate the<br />

energy consumption in WIS. Against this background, a sketchy method for assess energy<br />

consumption is proposed.<br />

Energy Consumption in a Waterworks<br />

raw water pumping<br />

alum & polymer feed<br />

rapid mix<br />

flocculation<br />

clarification<br />

gravity filtration<br />

filtration media<br />

hydraulic surface wash<br />

backwash pumping<br />

in-plant pumping<br />

Cl2 feed<br />

clearwell storage<br />

finished water pumping<br />

admin. labor. mainten.<br />

0,6<br />

1,4<br />

0,3<br />

0,0<br />

0,3<br />

0,5<br />

0,4<br />

0,0<br />

4,7<br />

3,0<br />

2,1<br />

11,1<br />

8,6<br />

67,0<br />

0 10 20 30 40 50 60 70<br />

energy consumption (%)<br />

Energy Consumption in a WWTP<br />

influent pump station<br />

headworks<br />

1st clarifier & sldg.pmp.<br />

AS aeration<br />

2nd clarifier & RAS<br />

thickener & sldg.pmp.<br />

effluent filters<br />

process water<br />

solids dewatering<br />

heating<br />

lighting<br />

post-aeration / Cl2 mix<br />

0,4<br />

3,7<br />

1,6<br />

0,9<br />

4,5<br />

3,6<br />

2,2<br />

3,1<br />

7,0<br />

7,1<br />

10,3<br />

Figure 32: Distribution of energy consumption in<br />

a waterworks (HDR 2001) and a WWTP (Metcalf & Eddy 2003)<br />

55,6<br />

0 10 20 30 40 50 60 70<br />

energy consumption (%)<br />

In WIS, energy is mainly used to drive motors, and it occurs mostly in two places, i.e.<br />

treatment plant and pump station. Figure 32 depict the distribution of energy consumption in