Chapter 3 Decision Support Model (IUWS-DSM) - Tubdok

Chapter 3 Decision Support Model (IUWS-DSM) - Tubdok

Chapter 3 Decision Support Model (IUWS-DSM) - Tubdok

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Chapter</strong> 3 · <strong>Decision</strong> <strong>Support</strong> <strong>Model</strong> (<strong>IUWS</strong>-<strong>DSM</strong>) 79<br />

The fourth part is sludge treatment, which can consume significant energy in treatment<br />

plants. Meantime, certain treatment processes can recover the energy, e.g. by anaerobic<br />

sludge digestion. Also, in some regions the sludge treatment is not the essential part in<br />

treatment plants. Thereby, sludge treatment is set up as an independent part.<br />

The fifth part is the auxiliary buildings. It stands as an individual part because of the<br />

building heating, which is related to the local climates. Heating system consumes<br />

significantly higher energy in cold area than in tropic area. It even can become the major<br />

energy consumption in treatment plants. In conveying system, pump stations are taken into<br />

account including booster pump station and lift satation.<br />

Assessment methods of energy consumption fall into two cases (Figure 33). Case 1 is<br />

especially for package plants, as all energy information is acquired from manufacturers.<br />

Case 2 is for rest of facilities. There are three methods to assess the energy consumption, i.e.<br />

1. based on the statistical data, 2. through the actual calculation, and 3. comparing to similar<br />

projects. In the <strong>IUWS</strong>-<strong>DSM</strong>, the unit measuring energy can be KWh/m 3 , KWh/capita, or<br />

KWh/day, whereby the model users choose the proper unit for their situation.<br />

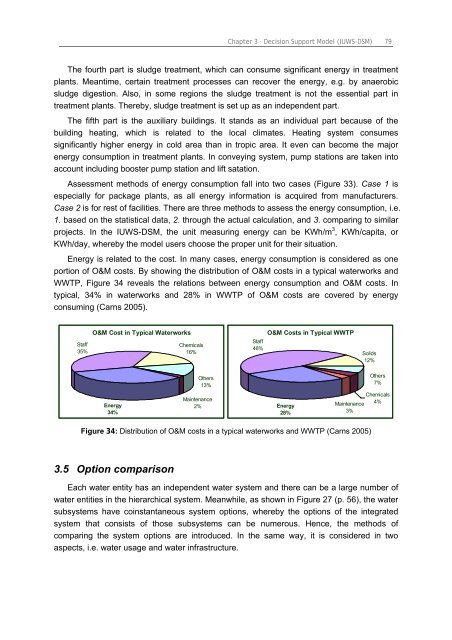

Energy is related to the cost. In many cases, energy consumption is considered as one<br />

portion of O&M costs. By showing the distribution of O&M costs in a typical waterworks and<br />

WWTP, Figure 34 reveals the relations between energy consumption and O&M costs. In<br />

typical, 34% in waterworks and 28% in WWTP of O&M costs are covered by energy<br />

consuming (Carns 2005).<br />

Staff<br />

35%<br />

O&M Cost in Typical Waterworks<br />

Energy<br />

34%<br />

Chemicals<br />

16%<br />

Others<br />

13%<br />

Maintenance<br />

2%<br />

O&M Costs in Typical WWTP<br />

Staff<br />

46%<br />

Energy<br />

28%<br />

Solids<br />

12%<br />

Others<br />

7%<br />

Chemicals<br />

4%<br />

Maintenance<br />

3%<br />

Figure 34: Distribution of O&M costs in a typical waterworks and WWTP (Carns 2005)<br />

3.5 Option comparison<br />

Each water entity has an independent water system and there can be a large number of<br />

water entities in the hierarchical system. Meanwhile, as shown in Figure 27 (p. 56), the water<br />

subsystems have coinstantaneous system options, whereby the options of the integrated<br />

system that consists of those subsystems can be numerous. Hence, the methods of<br />

comparing the system options are introduced. In the same way, it is considered in two<br />

aspects, i.e. water usage and water infrastructure.