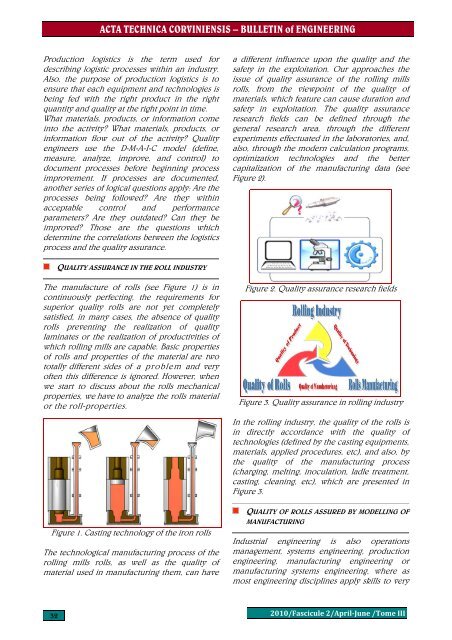

<strong>ACTA</strong> <strong>TECHNICA</strong> <strong>CORVINIENSIS</strong> – BULLETIN <strong>of</strong> ENGINEERINGProduction logistics is the term used fordescribing logistic processes within an industry.Also, the purpose <strong>of</strong> production logistics is toensure that each equipment and technologies isbeing fed with the right product in the rightquantity and quality at the right point in time.What materials, products, or information comeinto the activity? What materials, products, orinformation flow out <strong>of</strong> the activity? Qualityengineers use the D-M-A-I-C model (define,measure, analyze, improve, and control) todocument processes before beginning processimprovement. If processes are documented,another series <strong>of</strong> logical questions apply: Are theprocesses being followed? Are they withinacceptable control and performanceparameters? Are they outdated? Can they beimproved? Those are the questions whichdetermine the correlations between the logisticsprocess and the quality assurance.a different influence upon the quality and thesafety in the exploitation. Our approaches theissue <strong>of</strong> quality assurance <strong>of</strong> the rolling millsrolls, from the viewpoint <strong>of</strong> the quality <strong>of</strong>materials, which feature can cause duration andsafety in exploitation. The quality assuranceresearch fields can be defined through thegeneral research area, through the differentexperiments effectuated in the laboratories, and,also, through the modern calculation programs,optimization technologies and the bettercapitalization <strong>of</strong> the manufacturing data (seeFigure 2).QUALITY ASSURANCE IN THE ROLL INDUSTRYThe manufacture <strong>of</strong> rolls (see Figure 1) is incontinuously perfecting, the requirements forsuperior quality rolls are not yet completelysatisfied, in many cases, the absence <strong>of</strong> qualityrolls preventing the realization <strong>of</strong> qualitylaminates or the realization <strong>of</strong> productivities <strong>of</strong>which rolling mills are capable. Basic properties<strong>of</strong> rolls and properties <strong>of</strong> the material are twototally different sides <strong>of</strong> a problem and very<strong>of</strong>ten this difference is ignored. However, whenwe start to discuss about the rolls mechanicalproperties, we have to analyze the rolls materialor the roll-properties.Figure 2. Quality assurance research fieldsFigure 3. Quality assurance in rolling industryIn the rolling industry, the quality <strong>of</strong> the rolls isin directly accordance with the quality <strong>of</strong>technologies (defined by the casting equipments,materials, applied procedures, etc), and also, bythe quality <strong>of</strong> the manufacturing process(charging, melting, inoculation, ladle treatment,casting, cleaning, etc), which are presented inFigure 3.Figure 1. Casting technology <strong>of</strong> the iron rollsThe technological manufacturing process <strong>of</strong> therolling mills rolls, as well as the quality <strong>of</strong>material used in manufacturing them, can haveQUALITY OF ROLLS ASSURED BY MODELLING OFMANUFACTURINGIndustrial engineering is also operationsmanagement, systems engineering, productionengineering, manufacturing engineering ormanufacturing systems engineering, where asmost engineering disciplines apply skills to very322010/Fascicule 2/AprilJune /Tome III

<strong>ACTA</strong> <strong>TECHNICA</strong> <strong>CORVINIENSIS</strong> – BULLETIN <strong>of</strong> ENGINEERINGspecific areas, industrial engineering is appliedin every industry. Industrial engineers typicallyuse computer simulation, especially discreteevent simulation, for system analysis andevaluation. The computer is used to generate anumerical model <strong>of</strong> reality for the purposes <strong>of</strong>describing complex interaction amongcomponents <strong>of</strong> a system.Starting from the principle <strong>of</strong> modeling process,used as necessary basic instrument, both inphase <strong>of</strong> conception, as well as in the industrialtechnologies analysis, is determined theoptimum regimes <strong>of</strong> the cast rolls, from the viewfrom chemical composition, as one as the mostimportant parameters <strong>of</strong> disturbance <strong>of</strong> themanufacturing process. The enunciation <strong>of</strong>some mathematically modeling results,described through a number <strong>of</strong> multicomponentequations determined for the spaces with 3 theand 4 dimensions, as well as the generation <strong>of</strong>some regression surfaces, <strong>of</strong> some curves <strong>of</strong>levels, <strong>of</strong> the volumes <strong>of</strong> variation, <strong>of</strong> the lines <strong>of</strong>outlines <strong>of</strong> the volumes <strong>of</strong> variation <strong>of</strong> surfacesand the areas <strong>of</strong> variation <strong>of</strong> these, can berepresented and interpreted by technologistsand can be considerate diagrams <strong>of</strong> correlationbetween the analyzed variables. From this point<strong>of</strong> view the project is inscribes in context <strong>of</strong>scientific capitalization <strong>of</strong> the process and theindustrial technologies optimizations, on theway <strong>of</strong> the analysis and the mathematicalexperiment. The quality assurance through themodeling phenomenon is presented in Figure 4.Figure 4. Quality assurance through themodeling phenomenonThe character <strong>of</strong> the metallurgical processesoptimization is influenced by the complexpeculiarities <strong>of</strong> these, which take place into agreat number <strong>of</strong> variables (parameters) thatoperates independently or cumulate.For this reason, to analyze the metallurgicalprocesses is used, mainly, the statisticalfundamental methods that permit to drawnconclusions, from the observed values, about therepartition <strong>of</strong> the frequencies <strong>of</strong> variousparameters, about their interaction, aboutverification validity <strong>of</strong> certain premises, andabout the research <strong>of</strong> the dependencies amongdifferent parameters. However, the statisticalmethods <strong>of</strong> the metallurgical process analysesdo not solve a series <strong>of</strong> aspects regarding themode <strong>of</strong> establish the decisions for themanagement <strong>of</strong> the process. There<strong>of</strong>, parallelwith the statistical methods it was developedoptimization methods.The optimization <strong>of</strong> any technological processhas, as a base, a mathematical model. Thesearch for the best solution, for the truth,requests either to find, on the way <strong>of</strong> a study,definitive truths, or <strong>of</strong> relative valid truths, validonly in certain conditions, and which, in relationwith the definitive truths, include implicationsand errors.QUALITY OF ROLLS ASSURED BY THE LABORATORYEXPERIMENTSThe researches <strong>of</strong> durability in the exploitation<strong>of</strong> cast from cast-iron rolls, constitute ascientifically novelty, and experimentally definean important chapter from the thermal fatigue <strong>of</strong>the organs <strong>of</strong> machines in the movement <strong>of</strong>rotation, in variable temperature mediums. Hotrolling mills rolls work the in the variablecompound solicitations, due to laminationprocess and which repeated to regular intervals<strong>of</strong> time.All these phenomena, which are more or lessemphases depending on the type and typical <strong>of</strong>rolling mills, are not taking into consideration inthe classic calculus <strong>of</strong> rolls. If the study <strong>of</strong> therolls resistance is extended upon their durability,we must consider the whole complex <strong>of</strong> tensionswith mechanic-thermal influences.The research on durability in exploitation <strong>of</strong> hotrolling mills rolls assures relevant conditions forthe appropriation <strong>of</strong> the research methods <strong>of</strong> thethermal regimes that are submitted the rolls or2010/Fascicule 2/AprilJune /Tome III 33