ACTA TECHNICA CORVINIENSIS - Bulletin of Engineering

ACTA TECHNICA CORVINIENSIS - Bulletin of Engineering

ACTA TECHNICA CORVINIENSIS - Bulletin of Engineering

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

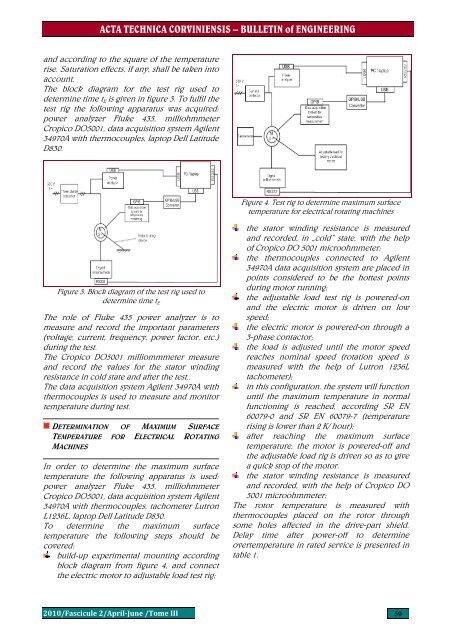

<strong>ACTA</strong> <strong>TECHNICA</strong> <strong>CORVINIENSIS</strong> – BULLETIN <strong>of</strong> ENGINEERINGand according to the square <strong>of</strong> the temperaturerise. Saturation effects, if any, shall be taken intoaccount.The block diagram for the test rig used todetermine time t E is given in figure 3. To fulfil thetest rig the following apparatus was acquired:power analyzer Fluke 435, milliohmmeterCropico DO5001, data acquisition system Agilent34970A with thermocouples, laptop Dell LatitudeD830.Figure 4. Test rig to determine maximum surfacetemperature for electrical rotating machinesFigure 3. Block diagram <strong>of</strong> the test rig used todetermine time t EThe role <strong>of</strong> Fluke 435 power analyzer is tomeasure and record the important parameters(voltage, current, frequency, power factor, etc.)during the test.The Cropico DO5001 milliommmeter measureand record the values for the stator windingresistance in cold state and after the test..The data acquisition system Agilent 34970A withthermocouples is used to measure and monitortemperature during test.DETERMINATION OF MAXIMUM SURFACETEMPERATURE FOR ELECTRICAL ROTATINGMACHINESIn order to determine the maximum surfacetemperature the following apparatus is used:power analyzer Fluke 435, milliohmmeterCropico DO5001, data acquisition system Agilent34970A with thermocouples, tachometer LutronL1236L, laptop Dell Latitude D830.To determine the maximumsurfacetemperature the following steps should becovered:build-up experimental mounting accordingblock diagram from figure 4, and connectthe electric motor to adjustable load test rig;the stator winding resistance is measuredand recorded, in „cold” state, with the help<strong>of</strong> Cropico DO 5001 microohmmeter;the thermocouples connected to Agilent34970A data acquisition system are placed inpoints considered to be the hottest pointsduring motor running;the adjustable load test rig is powered-onand the electric motor is driven on lowspeed;the electric motor is powered-on through a3-phase contactor;the load is adjusted until the motor speedreaches nominal speed (rotation speed ismeasured with the help <strong>of</strong> Lutron 1236Ltachometer);in this configuration, the system will functionuntil the maximum temperature in normalfunctioning is reached, according SR EN60079-0 and SR EN 60079-7 (temperaturerising is lower than 2 K/ hour);after reaching the maximum surfacetemperature, the motor is powered-<strong>of</strong>f andthe adjustable load rig is driven so as to givea quick stop <strong>of</strong> the motor.the stator winding resistance is measuredand recorded, with the help <strong>of</strong> Cropico DO5001 microohmmeter;The rotor temperature is measured withthermocouples placed on the rotor throughsome holes affected in the drive-part shield.Delay time after power-<strong>of</strong>f to determineovertemperature in rated service is presented intable 1.2010/Fascicule 2/AprilJune /Tome III 59