Shell Exploration & Production Contractor HSE Management - PDO

Shell Exploration & Production Contractor HSE Management - PDO

Shell Exploration & Production Contractor HSE Management - PDO

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

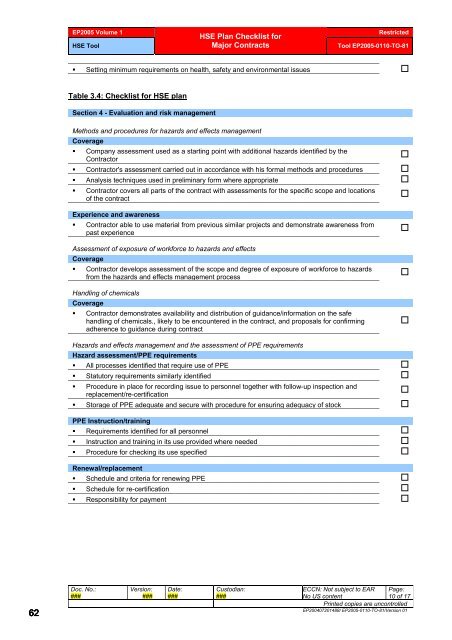

EP2005 Volume 1<strong>HSE</strong> Tool<strong>HSE</strong> Plan Checklist forMajor ContractsRestrictedTool EP2005-0110-TO-81• Setting minimum requirements on health, safety and environmental issuesTable 3.4: Checklist for <strong>HSE</strong> planSection 4 - Evaluation and risk managementMethods and procedures for hazards and effects managementCoverage• Company assessment used as a starting point with additional hazards identified by the<strong>Contractor</strong>• <strong>Contractor</strong>'s assessment carried out in accordance with his formal methods and procedures• Analysis techniques used in preliminary form where appropriate• <strong>Contractor</strong> covers all parts of the contract with assessments for the specific scope and locationsof the contractExperience and awareness• <strong>Contractor</strong> able to use material from previous similar projects and demonstrate awareness frompast experienceAssessment of exposure of workforce to hazards and effectsCoverage• <strong>Contractor</strong> develops assessment of the scope and degree of exposure of workforce to hazardsfrom the hazards and effects management processHandling of chemicalsCoverage• <strong>Contractor</strong> demonstrates availability and distribution of guidance/information on the safehandling of chemicals., likely to be encountered in the contract, and proposals for confirmingadherence to guidance during contractHazards and effects management and the assessment of PPE requirementsHazard assessment/PPE requirements• All processes identified that require use of PPE• Statutory requirements similarly identified• Procedure in place for recording issue to personnel together with follow-up inspection andreplacement/re-certification• Storage of PPE adequate and secure with procedure for ensuring adequacy of stockPPE Instruction/training• Requirements identified for all personnel• Instruction and training in its use provided where needed• Procedure for checking its use specifiedRenewal/replacement• Schedule and criteria for renewing PPE• Schedule for re-certification• Responsibility for paymentDoc. No.:###Version:###Date:###Custodian:###ECCN: Not subject to EAR Page:No US content10 of 17Printed copies are uncontrolledEP200407201488/ EP2005-0110-TO-81/Version 01B6