Exceeding Expectations

The Story of Wayne Brothers, Inc.

The Story of Wayne Brothers, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

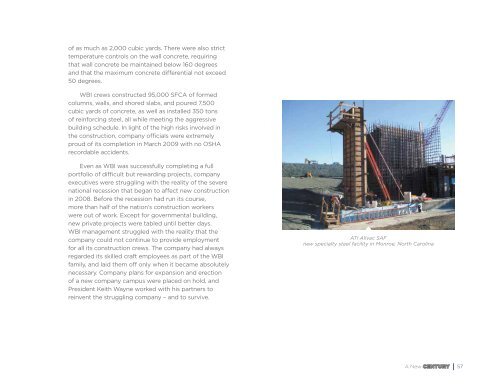

of as much as 2,000 cubic yards. There were also stricttemperature controls on the wall concrete, requiringthat wall concrete be maintained below 160 degreesand that the maximum concrete differential not exceed50 degrees.WBI crews constructed 95,000 SFCA of formedcolumns, walls, and shored slabs, and poured 7,500cubic yards of concrete, as well as installed 350 tonsof reinforcing steel, all while meeting the aggressivebuilding schedule. In light of the high risks involved inthe construction, company officials were extremelyproud of its completion in March 2009 with no OSHArecordable accidents.Even as WBI was successfully completing a fullportfolio of difficult but rewarding projects, companyexecutives were struggling with the reality of the severenational recession that began to affect new constructionin 2008. Before the recession had run its course,more than half of the nation’s construction workerswere out of work. Except for governmental building,new private projects were tabled until better days.WBI management struggled with the reality that thecompany could not continue to provide employmentfor all its construction crews. The company had alwaysregarded its skilled craft employees as part of the WBIfamily, and laid them off only when it became absolutelynecessary. Company plans for expansion and erectionof a new company campus were placed on hold, andPresident Keith Wayne worked with his partners toreinvent the struggling company – and to survive.ATI Allvac SAFnew specialty steel facility in Monroe, North CarolinaA New57