Exceeding Expectations

The Story of Wayne Brothers, Inc.

The Story of Wayne Brothers, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

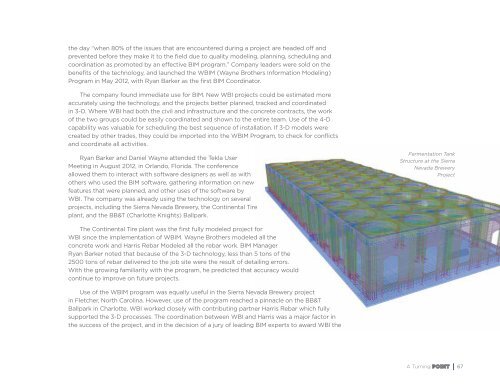

the day “when 80% of the issues that are encountered during a project are headed off andprevented before they make it to the field due to quality modeling, planning, scheduling andcoordination as promoted by an effective BIM program.” Company leaders were sold on thebenefits of the technology, and launched the WBIM (Wayne Brothers Information Modeling)Program in May 2012, with Ryan Barker as the first BIM Coordinator.The company found immediate use for BIM. New WBI projects could be estimated moreaccurately using the technology, and the projects better planned, tracked and coordinatedin 3-D. Where WBI had both the civil and infrastructure and the concrete contracts, the workof the two groups could be easily coordinated and shown to the entire team. Use of the 4-Dcapability was valuable for scheduling the best sequence of installation. If 3-D models werecreated by other trades, they could be imported into the WBIM Program, to check for conflictsand coordinate all activities.Ryan Barker and Daniel Wayne attended the Tekla UserMeeting in August 2012, in Orlando, Florida. The conferenceallowed them to interact with software designers as well as withothers who used the BIM software, gathering information on newfeatures that were planned, and other uses of the software byWBI. The company was already using the technology on severalprojects, including the Sierra Nevada Brewery, the Continental Tireplant, and the BB&T (Charlotte Knights) Ballpark.Fermentation TankStructure at the SierraNevada BreweryProjectThe Continental Tire plant was the first fully modeled project forWBI since the implementation of WBIM. Wayne Brothers modeled all theconcrete work and Harris Rebar Modeled all the rebar work. BIM ManagerRyan Barker noted that because of the 3-D technology, less than 5 tons of the2500 tons of rebar delivered to the job site were the result of detailing errors.With the growing familiarity with the program, he predicted that accuracy wouldcontinue to improve on future projects.Use of the WBIM program was equally useful in the Sierra Nevada Brewery projectin Fletcher, North Carolina. However, use of the program reached a pinnacle on the BB&TBallpark in Charlotte. WBI worked closely with contributing partner Harris Rebar which fullysupported the 3-D processes. The coordination between WBI and Harris was a major factor inthe success of the project, and in the decision of a jury of leading BIM experts to award WBI theA Turning67