Contents

Construction Management Plan - Baton Rouge Department of Public ...

Construction Management Plan - Baton Rouge Department of Public ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

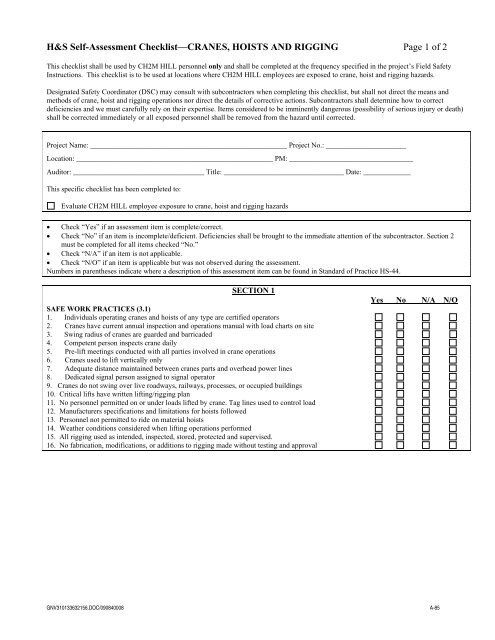

H&S Self-Assessment Checklist—CRANES, HOISTS AND RIGGING Page 1 of 2<br />

This checklist shall be used by CH2M HILL personnel only and shall be completed at the frequency specified in the project’s Field Safety<br />

Instructions. This checklist is to be used at locations where CH2M HILL employees are exposed to crane, hoist and rigging hazards.<br />

Designated Safety Coordinator (DSC) may consult with subcontractors when completing this checklist, but shall not direct the means and<br />

methods of crane, hoist and rigging operations nor direct the details of corrective actions. Subcontractors shall determine how to correct<br />

deficiencies and we must carefully rely on their expertise. Items considered to be imminently dangerous (possibility of serious injury or death)<br />

shall be corrected immediately or all exposed personnel shall be removed from the hazard until corrected.<br />

Project Name: ______________________________________________________ Project No.: ______________________<br />

Location: ______________________________________________________ PM: __________________________________<br />

Auditor: ____________________________________ Title: _________________________________ Date: _____________<br />

This specific checklist has been completed to:<br />

Evaluate CH2M HILL employee exposure to crane, hoist and rigging hazards<br />

• Check “Yes” if an assessment item is complete/correct.<br />

• Check “No” if an item is incomplete/deficient. Deficiencies shall be brought to the immediate attention of the subcontractor. Section 2<br />

must be completed for all items checked “No.”<br />

• Check “N/A” if an item is not applicable.<br />

• Check “N/O” if an item is applicable but was not observed during the assessment.<br />

Numbers in parentheses indicate where a description of this assessment item can be found in Standard of Practice HS-44.<br />

SECTION 1<br />

SAFE WORK PRACTICES (3.1)<br />

1. Individuals operating cranes and hoists of any type are certified operators<br />

2. Cranes have current annual inspection and operations manual with load charts on site<br />

3. Swing radius of cranes are guarded and barricaded<br />

4. Competent person inspects crane daily<br />

5. Pre-lift meetings conducted with all parties involved in crane operations<br />

6. Cranes used to lift vertically only<br />

7. Adequate distance maintained between cranes parts and overhead power lines<br />

8. Dedicated signal person assigned to signal operator<br />

9. Cranes do not swing over live roadways, railways, processes, or occupied buildings<br />

10. Critical lifts have written lifting/rigging plan<br />

11. No personnel permitted on or under loads lifted by crane. Tag lines used to control load<br />

12. Manufacturers specifications and limitations for hoists followed<br />

13. Personnel not permitted to ride on material hoists<br />

14. Weather conditions considered when lifting operations performed<br />

15. All rigging used as intended, inspected, stored, protected and supervised.<br />

16. No fabrication, modifications, or additions to rigging made without testing and approval<br />

Yes No N/A N/O<br />

GNV310133632156.DOC/090840008 A-85