environment

environment

environment

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Vol. 11 No. 1 2004<br />

ENVIRONMENT<br />

BioSealing: how micro-organisms become our little<br />

allies in repairing leaks<br />

John Lambert, Vasco Veenbergen, Eline van der Hoek & Sonja Karstens (GeoDelft), For more information:<br />

J.W.M.Lambert@geodelft.nl<br />

This article presents a new method for leak repair in underground constructions like sheet piles and contamination<br />

retaining barriers, being developed at GeoDelft in close cooperation with Delft University of Technology and Visser and<br />

Smit Bouw and funded by the Ministry of Economic Affairs. The method is called BioSealing and makes use of natural<br />

processes in the soil and the groundwater. BioSealing can be used to prevent water leaking through geotechnical<br />

constructions as well as to prevent migration of contaminants in contaminant retaining constructions. In this article the<br />

method of BioSealing is described and illustrated by results from laboratory experiments and the first results of current<br />

field experiments.<br />

1. Introduction<br />

In civil engineering and in <strong>environment</strong>al geotechnics<br />

underground water retaining barriers are frequently<br />

applied. In a lot of parts of the Netherlands a shallow<br />

ground water table is present. During civil engineering<br />

projects water barriers such as sheet piles need to be<br />

able to work under dry conditions. Underground water<br />

retaining constructions are designed to be impermeable.<br />

Although a general agreement exists that prevention of<br />

leaks has a high priority this appears not always to be<br />

possible. Unfortunately, in practice a lot of these (temporary)<br />

water barriers in underground constructions<br />

appear to be more permeable than they are designed<br />

for. Occasional leaks lead to the need for excessive<br />

groundwater extraction (involving higher costs and<br />

potential problems with drainage permissions), damage<br />

in the surroundings by settlement and therefore large<br />

delays in the construction time. For <strong>environment</strong>al<br />

purposes water retaining barriers are designed to prevent<br />

migration of contaminants. Examples are underground<br />

barriers underneath waste disposal sites, chemical<br />

industry plants and gasoline stations. These barriers<br />

may have an extremely low permeability when they are<br />

constructed but have to stay in place for a long time or<br />

even “forever”. During that lifetime the barrier might be<br />

damaged and therefore not prevent the contaminants<br />

from migrating through the groundwater anymore. This<br />

contaminant migration may lead to <strong>environment</strong>al risks<br />

and/ or higher amounts of groundwater to be extracted<br />

with cleaning and disposal costs.<br />

Not all leaks need to be restored. Whether or not a leak<br />

needs to be repaired depends on the risks involved, the<br />

costs and the fall-back scenarios. After it is decided<br />

that the leak needs to be repaired a number of methods<br />

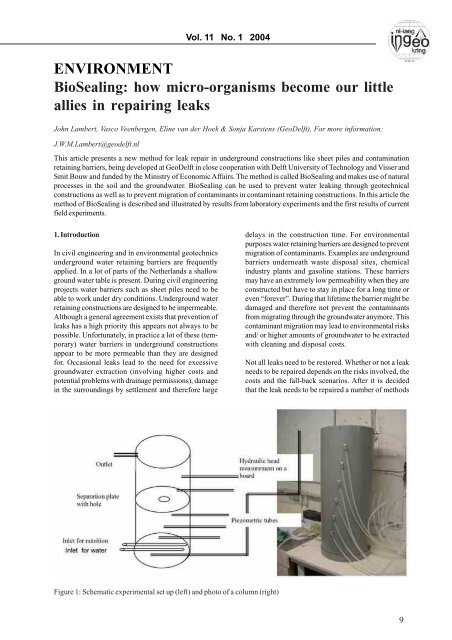

Figure 1: Schematic experimental set up (left) and photo of a column (right)<br />

9