environment

environment

environment

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Vol. 11 No. 1 2004<br />

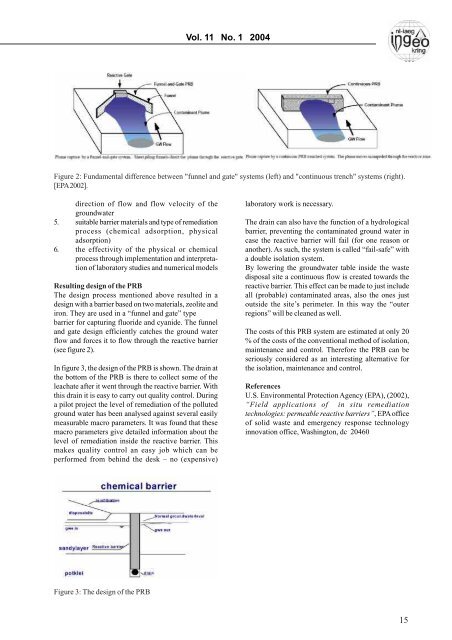

Figure 2: Fundamental difference between "funnel and gate" systems (left) and "continuous trench" systems (right).<br />

[EPA 2002].<br />

direction of flow and flow velocity of the<br />

groundwater<br />

5. suitable barrier materials and type of remediation<br />

process (chemical adsorption, physical<br />

adsorption)<br />

6. the effectivity of the physical or chemical<br />

process through implementation and interpretation<br />

of laboratory studies and numerical models<br />

Resulting design of the PRB<br />

The design process mentioned above resulted in a<br />

design with a barrier based on two materials, zeolite and<br />

iron. They are used in a “funnel and gate” type<br />

barrier for capturing fluoride and cyanide. The funnel<br />

and gate design efficiently catches the ground water<br />

flow and forces it to flow through the reactive barrier<br />

(see figure 2).<br />

In figure 3, the design of the PRB is shown. The drain at<br />

the bottom of the PRB is there to collect some of the<br />

leachate after it went through the reactive barrier. With<br />

this drain it is easy to carry out quality control. During<br />

a pilot project the level of remediation of the polluted<br />

ground water has been analysed against several easily<br />

measurable macro parameters. It was found that these<br />

macro parameters give detailed information about the<br />

level of remediation inside the reactive barrier. This<br />

makes quality control an easy job which can be<br />

performed from behind the desk – no (expensive)<br />

laboratory work is necessary.<br />

The drain can also have the function of a hydrological<br />

barrier, preventing the contaminated ground water in<br />

case the reactive barrier will fail (for one reason or<br />

another). As such, the system is called “fail-safe” with<br />

a double isolation system.<br />

By lowering the groundwater table inside the waste<br />

disposal site a continuous flow is created towards the<br />

reactive barrier. This effect can be made to just include<br />

all (probable) contaminated areas, also the ones just<br />

outside the site’s perimeter. In this way the “outer<br />

regions” will be cleaned as well.<br />

The costs of this PRB system are estimated at only 20<br />

% of the costs of the conventional method of isolation,<br />

maintenance and control. Therefore the PRB can be<br />

seriously considered as an interesting alternative for<br />

the isolation, maintenance and control.<br />

References<br />

U.S. Environmental Protection Agency (EPA), (2002),<br />

“Field applications of in situ remediation<br />

technologies: permeable reactive barriers”, EPA office<br />

of solid waste and emergency response technology<br />

innovation office, Washington, dc 20460<br />

Figure 3: The design of the PRB<br />

15