You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Ventures<br />

usiness prole<br />

SeQuential Fuels<br />

the Next Generation<br />

Biofuel manufacturer grows with<br />

demand for plant-based power<br />

written by Jennifer Hughes<br />

photos by Aubrie LeGault<br />

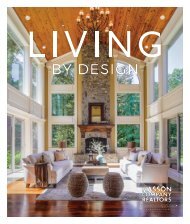

Sequentials COO, Alan Twigg,<br />

and founder, Ian Hill right,<br />

show off the green roof of their<br />

flagship station in Eugene.<br />

IN EUGENE, TWO ROYAL BLUE and<br />

goldenrod yellow SeQuential Biofuels stations<br />

stand out among a sea of Shell, 76 and<br />

Chevron gas stations. The latter group is of<br />

the typical gas-and-go variety with unleaded<br />

outside and trans-fat snacks on the inside.<br />

The other sells biodiesel, yerba mate and organic<br />

produce under a green roof.<br />

SeQuential BioFuels is Eugene’s greenest<br />

fueling station and is ground zero for cutting-edge<br />

alternative fuels while also turning<br />

organic food into roadside convenience<br />

snacks. In the ordinary filling station, the gas<br />

is petroleum based and the fats sit on the<br />

shelves. At SeQuential, the fats and greases<br />

are in the pump and comprise the mostly<br />

soy-based fuel.<br />

Fed up with “Big Oil”, Thomas Endicott, Ian<br />

Hill and Tyson Keever began making biodiesel in Hill’s garage in 2000, using<br />

leftover cooking oil collected from restaurants. Local demand for their<br />

biodiesel grew dramatically, and in 2004, they teamed with Pacific Biodiesel<br />

to open Oregon’s first commercial-scale biodiesel production plant.<br />

SeQuential takes in Oregon-grown canola and waste vegetable oils<br />

from the region, and converts this feedstock into biodiesel through a process<br />

known as “transesterification.” The result is a cleaner burning fuel that<br />

is biodegradable. Its byproduct is carbon dioxide, the same compound<br />

animals exhale. The tailpipe emissions from a petroleum-burning engine,<br />

by contrast, are carbon monoxide; smog’s main component, nitrous oxide<br />

and unburned hydrocarbons.<br />

Today SeQuential has its own oil processing plant and a fleet of thirty<br />

biofueled trucks that collect oils in Western states. The company’s biodiesel<br />

plant in Salem produces 17 million gallons of biodiesel fuel per year.<br />

That fuel is multiples less carbon-intensive than petroleum diesel, making<br />

it one of the lowest carbon fuels commercially available in the United<br />

States. Additionally, SeQuential Pacific Biodiesel is a zero-waste facility,<br />

deploying a proprietary process that produces no waste water, and generates<br />

heat and power from heavy fats and oils that cannot be processed.<br />

Atop it all is a distillation column to capture and re-use methanol released<br />

in the process. This facility provides fuel for a network of nearly<br />

seventy consumer retail stations.<br />

Thousands of plants grow on its flagship rooftop in Eugene. Inside, dozens<br />

of local food products from more than seventy-five local companies<br />

fill the shelves. Fresh sandwiches, organic coffee and pastries from nearby<br />

Sweet Life Patisserie give a fresh twist on convenience food. One filling<br />

station’s sandwich special is made from Applegate ham, local gluten-free<br />

bread and organic produce.<br />

In addition to the living roof, half of SeQuential’s annual electricity<br />

needs are supplanted by its passive solar building design.<br />

Both federal and state tax credits and mandates have played a role in<br />

the creation and viability of alternative fuel companies. In 2007, the State<br />

of Oregon created a business energy tax credit (BETC) to aid in the development<br />

and distribution of alternative energy resources. Under this program,<br />

the state successfully courted solar panel manufacturers, electric<br />

car makers, wind power projects and biofuel manufacturers.<br />

“We have a state level mandate for a renewable fuel standard, which<br />

stipulates five percent biodiesel of all diesel sold in Oregon, and it doesn’t<br />

stipulate where that biodiesel must come from,” Hill says. “We still compete<br />

to fill that demand. Competition is good; it’s not a handout from the<br />

government at all, by any stretch of the imagination.”<br />

As part of a wide-ranging renewable energy portfolio, Oregon law requires<br />

all gasoline retailers to blend their petroleum fuel with 10 percent<br />

ethanol. Oregon also offers residents a state income tax credit up to $200<br />

for documented use of high blends of biodiesel.<br />

While Hill and Keever have witnessed other biodiesel companies shooting<br />

for the moon and failing, their approach is moderate growth. Their focus<br />

is to create high-quality, low-emission fuel products for Oregonians and<br />

the Pacific Northwest—with or without government assistance.<br />

“From the beginning we’ve been very determined to develop a business<br />

that will thrive without any government programs or incentives,<br />

and we feel like we’re certainly on our way to that,” says Hill. “We are<br />

out to create something that is really sustainable, and we want it to be<br />

around for our grandkids.”<br />

60 <strong>1859</strong> oregon's mAgAzine SEPT OCT <strong>2012</strong>