- Page 1: ISSN-L=1454-7376 (Print)-ISSN 1454-

- Page 4 and 5: 13. CIORNEA 1 Elena, TUTU Elena, CO

- Page 6 and 7: 38. 39. 40. 41. 42. 43. 44. 45. 46.

- Page 8 and 9: 64. FILIMON V.R., NICULAUA M., MIHA

- Page 10 and 11: 91. NEGREA Roxana, ZLATI Cristina -

- Page 12 and 13: 12. BEJAN 1 Carmen, VIŞOIU Emilia

- Page 14 and 15: 38. 39. 40. 41. 42. 43. 44. 45. 46.

- Page 16 and 17: 64. 65. 66. 67. 68. 69. 70. 71. 72.

- Page 18 and 19: compoziţii vegetale pentru amenaj

- Page 20 and 21: INTRODUCTION Due to the increased f

- Page 22 and 23: Salicylates provided an increased y

- Page 24 and 25: total mass. However, it is required

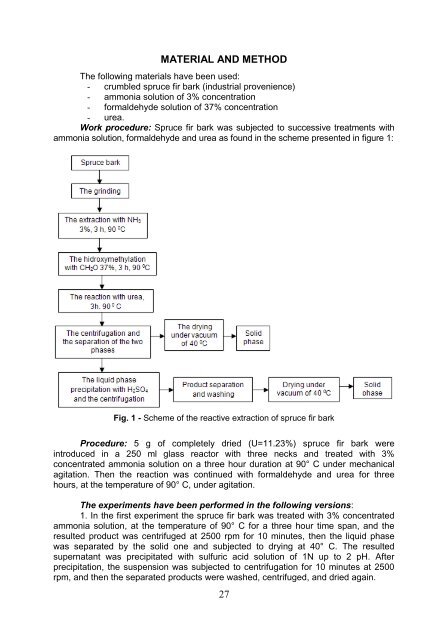

- Page 28 and 29: 2. In the second experiment the spr

- Page 30 and 31: CONCLUSIONS 1. The extraction of sp

- Page 32 and 33: INTRODUCTION Lately, one may notice

- Page 34 and 35: ions leads to a retention rate grow

- Page 36 and 37: CONCLUSIONS 1. The stability of tre

- Page 38 and 39: fundamental process in coupled dyna

- Page 40 and 41: x� 1 � x 2 x� 2 � x� 3

- Page 42 and 43: Fig. 7 - (2y1(t) -, x1(t) -, for p=

- Page 44 and 45: showed that the existence of fracta

- Page 46 and 47: Fig. 3 - The fractal dimension for

- Page 48 and 49: From figure 6 we can see that the e

- Page 50 and 51: INTRODUCTION Nichel as ultramicroel

- Page 52 and 53: Table 2 POD activity (conventional

- Page 54 and 55: REFERENCES 1. Brown P.H., Welch R.M

- Page 56 and 57: Actually, SSR markers are considere

- Page 58 and 59: Table 1 (continuation) Inherintance

- Page 60 and 61: Drofa Rf genotype was positioned in

- Page 62 and 63: Center for Biotechnology Informatio

- Page 64 and 65: Fig. 2 - RRM_1- RNA recognition mot

- Page 66 and 67: 4. Mackenzie S.A., McIntosh L., 199

- Page 68 and 69: MATERIAL AND METHOD Six fertility r

- Page 70 and 71: Fig. 1 - Densitometry analysis of O

- Page 72 and 73: CONCLUSIONS 1. Screening of three O

- Page 74 and 75: The first flow cytometers quantifie

- Page 76 and 77:

Our data confirm the previous resul

- Page 78 and 79:

7. Dydak M., Kolano B., Nowak T., S

- Page 80 and 81:

prezenţa şi tipul aberaţiilor cr

- Page 82 and 83:

The value of the mitotic index was

- Page 84 and 85:

CONCLUSIONS 1. The value of the mit

- Page 86 and 87:

INTRODUCTION Like the other plants,

- Page 88 and 89:

Fig. 3 - Histogram representing the

- Page 90 and 91:

Among the tested control plants, th

- Page 92 and 93:

their control techniques. The main

- Page 94 and 95:

figure 2, and, in their analysis it

- Page 96 and 97:

CONCLUSIONS The analysis of experim

- Page 98 and 99:

metabolism can be easily detected b

- Page 100 and 101:

PAL activity (∆E/mg prot.) PAL ac

- Page 102 and 103:

Academiei de Ştiinţe a Moldovei.

- Page 104 and 105:

efectuate investigaţii biochimice

- Page 106 and 107:

UI compared to 31,53 UI, the value

- Page 108 and 109:

3. The evolution of superoxide dism

- Page 110 and 111:

the pyridazine derivatives in growt

- Page 112 and 113:

Pyridazine derivatives tested did n

- Page 114 and 115:

8. Drochioiu G., Maftei M., Mangala

- Page 116 and 117:

according to the classification to

- Page 118 and 119:

formazan/g, a mixture of micronutri

- Page 120 and 121:

4. At 7 days after inoculation of t

- Page 122 and 123:

the root types of vascular bundles

- Page 124 and 125:

cells disposed more compacted at su

- Page 126 and 127:

CONCLUSIONS 1. The general structur

- Page 128 and 129:

INTRODUCTION Never in the history o

- Page 130 and 131:

Attracting social partners in the e

- Page 132 and 133:

CONCLUSIONS 1. Evaluator and tutors

- Page 134 and 135:

firms seek resources and new ways t

- Page 136 and 137:

companies in the wine sector. Indic

- Page 138 and 139:

From the analysis of figure 1 can b

- Page 140 and 141:

warning about the practice of copyi

- Page 142 and 143:

success to an extent far greater th

- Page 144 and 145:

CONCLUSIONS 1. At regional level th

- Page 146 and 147:

team that he leads, establishing re

- Page 148 and 149:

Nr. crt. NAME OF CROPS Areas cultiv

- Page 150 and 151:

management skills necessary to admi

- Page 152 and 153:

personalities. The education by mea

- Page 154 and 155:

The final part of the activities wa

- Page 156 and 157:

CONCLUSIONS The activities carried

- Page 158 and 159:

din punct de vedere al creşterii v

- Page 160 and 161:

percentage of + 58 %. The productio

- Page 162 and 163:

The second component reflects the l

- Page 164 and 165:

It should be noted that the net inc

- Page 166 and 167:

CONCLUSIONS 1. Studies have shown t

- Page 168 and 169:

variety were given mineral fertiliz

- Page 170 and 171:

40.7 g compared to the control. In

- Page 172 and 173:

In super intensive orchards of spec

- Page 174 and 175:

3 years of fruiting, 72.9 t/ha. The

- Page 176 and 177:

Replacing the old varieties, that h

- Page 178 and 179:

Golden Reinders varieties on the br

- Page 180 and 181:

varieties introduced in the country

- Page 182 and 183:

and H. Gilbert (1843), at the Rotha

- Page 184 and 185:

Nr. crt. Table 1 Distances and dens

- Page 186 and 187:

CONCLUSIONS 1. Technological factor

- Page 188 and 189:

Knowledge of the main agrobiologica

- Page 190 and 191:

The following graph, the diameter g

- Page 192 and 193:

CONCLUSIONS 1. The analysis main mo

- Page 194 and 195:

Vegetable production is marked by a

- Page 196 and 197:

vegetable sprouts. Optimum growing

- Page 198 and 199:

Ecological and physiological charac

- Page 200 and 201:

MATERIAL AND METHOD The carrying ou

- Page 202 and 203:

Question: “Would you buy ecologic

- Page 204 and 205:

Thus, 12.9% out of the persons inte

- Page 206 and 207:

MATERIAL AND METHOD The biological

- Page 208 and 209:

No crt. 1 Results regarding the fre

- Page 210 and 211:

CONCLUSIONS 1. The meteorological-p

- Page 212 and 213:

MATERIAL AND METHOD The research wa

- Page 214 and 215:

In the stationary microfarm Maxim o

- Page 216 and 217:

Tomato Granadero F1 row Tomato Gran

- Page 218 and 219:

MATERIAL AND METHOD The breeding wo

- Page 220 and 221:

No. Followed character The main cha

- Page 222 and 223:

L9 L10 Mt Fig. 1 - The selection of

- Page 224 and 225:

INTRODUCTION Increasing demand for

- Page 226 and 227:

REFERENCES 1. Gozob T., Micu Chiria

- Page 228 and 229:

of reduced energy consumption, have

- Page 230 and 231:

The results obtained for apples pro

- Page 232 and 233:

Pruning influence on apple producti

- Page 234 and 235:

mahaleb succeeds in the NE of Roman

- Page 236 and 237:

in the maturation stadium, have cra

- Page 238 and 239:

its acidity covers an intermediary

- Page 240 and 241:

eacts with the basic solution, the

- Page 242 and 243:

and mildew vulnerability, obtained

- Page 244 and 245:

Analyzing data on the amount of bio

- Page 246 and 247:

INTRODUCTION Numerous scientists ar

- Page 248 and 249:

- Arthemisia annua, cultivated in c

- Page 250 and 251:

much more decorative, framing very

- Page 252 and 253:

potential, were realised both on na

- Page 254 and 255:

flowers grouped in umbelliform infl

- Page 256 and 257:

3. Function of ornamental features

- Page 258 and 259:

and have species with different eco

- Page 260 and 261:

It is cultivated as ornamental gras

- Page 262 and 263:

„Silberfeder Miscanthus sinensis

- Page 264 and 265:

INTRODUCTION Located in the SE of R

- Page 266 and 267:

3. Sedum urvillei DC. (sin. Sedum s

- Page 268 and 269:

CONCLUSIONS 1. The spontaneous flor

- Page 270 and 271:

1. - the bush shape; 2. - the vigou

- Page 272 and 273:

Table 4 The quality evaluation shee

- Page 274 and 275:

value of roses. Through this we can

- Page 276 and 277:

three meters between rows and one m

- Page 278 and 279:

Table 3 Fruit production of apple c

- Page 280 and 281:

CONCLUSIONS The production of apple

- Page 282 and 283:

INTRODUCTION Researches whose resul

- Page 284 and 285:

The spatial distribution of suitabi

- Page 286 and 287:

3. The most favorable for the wine

- Page 288 and 289:

MATERIAL AND METHOD The ecological

- Page 290 and 291:

CONCLUSIONS The ecological index ca

- Page 292 and 293:

of rose wines differing according t

- Page 294 and 295:

The changes of color components are

- Page 296 and 297:

Blending means - beyond the combina

- Page 298 and 299:

The V[p,s] property values for the

- Page 300 and 301:

No major changes of the hierarchy a

- Page 302 and 303:

another essential condition: the ca

- Page 304 and 305:

having a fish tradition, for a cons

- Page 306 and 307:

The environment conditions may favo

- Page 308 and 309:

Fig. 1 - Chemical formula of vitami

- Page 310 and 311:

substances with a protective role d

- Page 312 and 313:

~ Is allergic activities (www.trata

- Page 314 and 315:

and Grădinariu G, 2000), cherry pr

- Page 316 and 317:

Fruits moisture ranged between 79.6

- Page 318 and 319:

5. The data obtained, are within th

- Page 320 and 321:

Plums contain large quantities of s

- Page 322 and 323:

Regarding the fact that all cultiva

- Page 324 and 325:

other compounds, while at the Dâmb

- Page 326 and 327:

statistic-mathematical multi-variat

- Page 328 and 329:

In order to ensure more fidelity in

- Page 330 and 331:

INTRODUCTION Climate change has an

- Page 332 and 333:

Fig. 2 - TblClima table structure T

- Page 334 and 335:

and provides information on phenolo

- Page 336 and 337:

INTRODUCTION It is a common knowled

- Page 338 and 339:

A tendency towards enhancement of l

- Page 340 and 341:

At the same time, the results of yi

- Page 342 and 343:

phénolique constitue une donne ind

- Page 344 and 345:

plus petites que pur le Merlot ou l

- Page 346 and 347:

Suite aux dégustations organolépt

- Page 348 and 349:

wines. A fourth variety, Gewürtztr

- Page 350 and 351:

The highest quantities are found in

- Page 352 and 353:

CONCLUSIONS 1. In Tămâioasă rom

- Page 354 and 355:

INTRODUCTION The physical-chemical

- Page 356 and 357:

N o Technologi cal variant Alcoho l

- Page 358 and 359:

REFERENCES 1. Cotea D.V., 1985 - Tr

- Page 360 and 361:

asic wine and the yeasts triggering

- Page 362 and 363:

Fig. 2 - Dynamics of reducing sugar

- Page 364 and 365:

Pressure was determined since the 1

- Page 366 and 367:

character that may be frequently fo

- Page 368 and 369:

To totally eliminate the germs of b

- Page 370 and 371:

Aluminum vessels used for the prepa

- Page 372 and 373:

Influence of technological phases o

- Page 374 and 375:

Table 4 Losses of vitamin C recorde

- Page 376 and 377:

ascorbic, E301 sodium ascorbate, E3

- Page 378 and 379:

anthocyanin pigments, flavonoids, t

- Page 380 and 381:

economically speaking, due to very

- Page 382 and 383:

REFERENCES 1. Adams J. B., 1973 - T

- Page 384 and 385:

with ascorbic acid are major antiox

- Page 386 and 387:

cabbages, which have antioxidant ac

- Page 388 and 389:

5. Correlation between total phenol

- Page 390 and 391:

MATERIAL AND METHOD Experiences wer

- Page 392 and 393:

compared to the control and lowest

- Page 394 and 395:

and development, increased producti

- Page 396 and 397:

Conversely, the cost increases and

- Page 398 and 399:

CONCLUSIONS 1. In the central area

- Page 400 and 401:

INTRODUCTION The physical degradati

- Page 402 and 403:

The laboratory test rig has the fol

- Page 404 and 405:

Acknowledgements. The laboratory te

- Page 406 and 407:

Factor B = NITROGEN (kg N / ha): b1

- Page 408 and 409:

Table 3 Influence of nitrogen and p

- Page 410 and 411:

4. Regarding the influence of incre

- Page 412 and 413:

the two objective and important cha

- Page 414 and 415:

- very hard summer consistency on s

- Page 416 and 417:

weather and antropic factors of the

- Page 418 and 419:

Wander and co., 2002 considers that

- Page 420 and 421:

Ecological climatic factors Average

- Page 422 and 423:

7. Januszek K, 1999 - Actywnosc enz

- Page 424 and 425:

using the most suitable rootstocks

- Page 426 and 427:

Soil porosity. Large pore diverse l

- Page 428 and 429:

low, which does not influence the d

- Page 430 and 431:

2005, 2009 a, 2009 b, Borza I. et a

- Page 432 and 433:

Table 5 The total water consumption

- Page 434 and 435:

CONCLUSIONS 1. At unirrigated potat

- Page 436 and 437:

irrigation systems the paper studie

- Page 438 and 439:

The crop coefficients (Kc) for the

- Page 440 and 441:

for respectively month. The differe

- Page 442 and 443:

MATERIAL AND METHOD In order to per

- Page 444 and 445:

In order to facilitate the access o

- Page 446 and 447:

The water sources absorbed by the b

- Page 448 and 449:

compaction of the cultivated horizo

- Page 450 and 451:

machinery wheals, we can observe a

- Page 452 and 453:

CONCLUSIONS 1. The increase of the

- Page 454 and 455:

These compounds are efficient in co

- Page 456 and 457:

CONCLUSIONS The fight against this

- Page 458 and 459:

INTRODUCTION Timis River, the riche

- Page 460 and 461:

Gavojdia sampling point is located

- Page 462 and 463:

0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0 0.0

- Page 464 and 465:

Recording as changes in the structu

- Page 466 and 467:

The earthworms species collected in

- Page 468 and 469:

MATERIAL AND METHOD The research wa

- Page 470 and 471:

In the Farm Rediu Iasi from table 3

- Page 472 and 473:

36 63 472 82 Vasile Adamachi Rediu

- Page 474 and 475:

gathered from May to July. Gatherin

- Page 476 and 477:

-on first harvest on 26.05 I collec

- Page 478 and 479:

6 06.06 Folicur Actelic 7 13.06 Cla

- Page 480 and 481:

MATERIAL AND METHOD The biological

- Page 482 and 483:

The differences from the three-year

- Page 484 and 485:

The analysis of data recorded in ta

- Page 486 and 487:

MATERIAL AND METHOD The research wa

- Page 488 and 489:

Nr. Phenologic phase 1 White button

- Page 490 and 491:

It has taken this choice, because i

- Page 492 and 493:

et al., 2007) and convert the dange

- Page 494 and 495:

According to data from table 3 the

- Page 496 and 497:

MATERIAL AND METHOD The experiences

- Page 498 and 499:

From the second year of culture, pl

- Page 500 and 501:

During this study it has been found

- Page 502 and 503:

MATERIAL AND METHOD The two farms s

- Page 504 and 505:

The project contains these measures

- Page 506 and 507:

and of downstream dams that, beginn

- Page 508 and 509:

and urban creations, we link this w

- Page 510 and 511:

Also, he is one of the first creato

- Page 512 and 513:

3. In the development of such proje

- Page 514 and 515:

archeological signs with the urbani

- Page 516 and 517:

As long as the towns of medieval Mo

- Page 518 and 519:

in the palace, centrally located, o

- Page 520 and 521:

the job or to other interest points

- Page 522 and 523:

The modernization of these public m

- Page 524 and 525:

CONCLUSIONS The concept represents

- Page 526 and 527:

1975; Enache I., 2002). Research co

- Page 528 and 529:

Fig.3 - Analysis of the model As a

- Page 530 and 531:

made of plastic (for economic model

- Page 532 and 533:

The simplicity of the effect is alw

- Page 534 and 535:

a) Pyrus calleryana b) Pyrus amygda

- Page 536 and 537:

The quantity of colour plays an imp

- Page 538 and 539:

unique, colourful foliage, like the

- Page 540 and 541:

Another decorative specie is Japane

- Page 542 and 543:

foliage greens, but in other colour

- Page 544 and 545:

imagination was regarded as having

- Page 546 and 547:

specific way of interpreting realit

- Page 548 and 549:

MATERIAL AND METHOD The plant mater

- Page 550 and 551:

following varieties in the South of

- Page 552 and 553:

contents of the above compounds is

- Page 554 and 555:

a number of about 40 ample windthro

- Page 556 and 557:

Fig. 2 - EEF index values before wi

- Page 558 and 559:

ecoprotective effectiveness is main

- Page 560 and 561:

independence, too (Adams S. et al.,

- Page 562 and 563:

RESULTS AND DISCUSSIONS Results of

- Page 564 and 565:

2,3°C the specific cost is 16,07

- Page 566 and 567:

INTRODUCTION Dealu Bujorului vineya

- Page 568 and 569:

In August, when the grape vine begi

- Page 570 and 571:

So, the wines made by maceration-fe

- Page 572 and 573:

Forest "Dumbrava Sibiului" in 1900-

- Page 574 and 575:

Family P A P I L I O N I D A E Genu

- Page 576 and 577:

thousands of collection of this dat

- Page 578:

Editorial Consultant: Vasile VÎNTU