SAP Production Planning Table

SAP Production Planning Table

SAP Production Planning Table

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

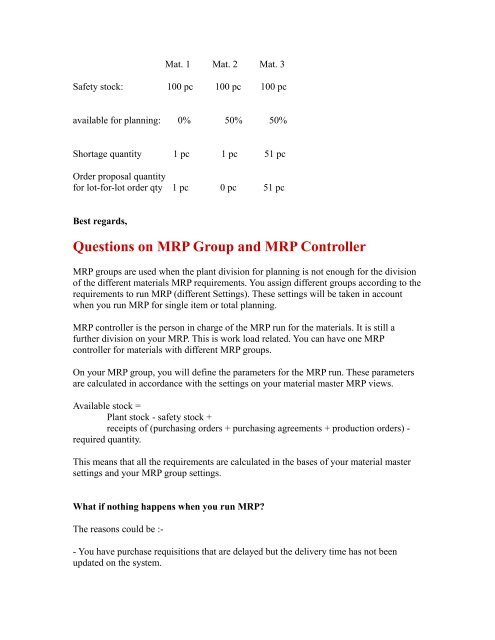

Mat. 1 Mat. 2 Mat. 3<br />

Safety stock: 100 pc 100 pc 100 pc<br />

available for planning: 0% 50% 50%<br />

Shortage quantity 1 pc 1 pc 51 pc<br />

Order proposal quantity<br />

for lot-for-lot order qty 1 pc 0 pc 51 pc<br />

Best regards,<br />

Questions on MRP Group and MRP Controller<br />

MRP groups are used when the plant division for planning is not enough for the division<br />

of the different materials MRP requirements. You assign different groups according to the<br />

requirements to run MRP (different Settings). These settings will be taken in account<br />

when you run MRP for single item or total planning.<br />

MRP controller is the person in charge of the MRP run for the materials. It is still a<br />

further division on your MRP. This is work load related. You can have one MRP<br />

controller for materials with different MRP groups.<br />

On your MRP group, you will define the parameters for the MRP run. These parameters<br />

are calculated in accordance with the settings on your material master MRP views.<br />

Available stock =<br />

Plant stock - safety stock +<br />

receipts of (purchasing orders + purchasing agreements + production orders) -<br />

required quantity.<br />

This means that all the requirements are calculated in the bases of your material master<br />

settings and your MRP group settings.<br />

What if nothing happens when you run MRP?<br />

The reasons could be :-<br />

- You have purchase requisitions that are delayed but the delivery time has not been<br />

updated on the system.