Project Green District Energy Feasibility Study - Partners in Project ...

Project Green District Energy Feasibility Study - Partners in Project ...

Project Green District Energy Feasibility Study - Partners in Project ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TRCA Pearson Eco-Bus<strong>in</strong>ess Zone <strong>District</strong> <strong>Energy</strong> <strong>Feasibility</strong> <strong>Study</strong> 10 April 2012<br />

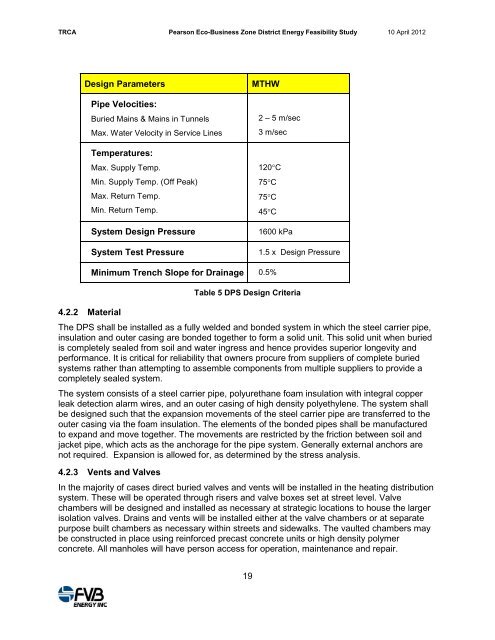

Design Parameters MTHW<br />

Pipe Velocities:<br />

Buried Ma<strong>in</strong>s & Ma<strong>in</strong>s <strong>in</strong> Tunnels<br />

Max. Water Velocity <strong>in</strong> Service L<strong>in</strong>es<br />

Temperatures:<br />

Max. Supply Temp.<br />

M<strong>in</strong>. Supply Temp. (Off Peak)<br />

Max. Return Temp.<br />

M<strong>in</strong>. Return Temp.<br />

19<br />

2 – 5 m/sec<br />

3 m/sec<br />

120°C<br />

75°C<br />

75°C<br />

45°C<br />

System Design Pressure 1600 kPa<br />

System Test Pressure 1.5 x Design Pressure<br />

M<strong>in</strong>imum Trench Slope for Dra<strong>in</strong>age 0.5%<br />

Table 5 DPS Design Criteria<br />

4.2.2 Material<br />

The DPS shall be <strong>in</strong>stalled as a fully welded and bonded system <strong>in</strong> which the steel carrier pipe,<br />

<strong>in</strong>sulation and outer cas<strong>in</strong>g are bonded together to form a solid unit. This solid unit when buried<br />

is completely sealed from soil and water <strong>in</strong>gress and hence provides superior longevity and<br />

performance. It is critical for reliability that owners procure from suppliers of complete buried<br />

systems rather than attempt<strong>in</strong>g to assemble components from multiple suppliers to provide a<br />

completely sealed system.<br />

The system consists of a steel carrier pipe, polyurethane foam <strong>in</strong>sulation with <strong>in</strong>tegral copper<br />

leak detection alarm wires, and an outer cas<strong>in</strong>g of high density polyethylene. The system shall<br />

be designed such that the expansion movements of the steel carrier pipe are transferred to the<br />

outer cas<strong>in</strong>g via the foam <strong>in</strong>sulation. The elements of the bonded pipes shall be manufactured<br />

to expand and move together. The movements are restricted by the friction between soil and<br />

jacket pipe, which acts as the anchorage for the pipe system. Generally external anchors are<br />

not required. Expansion is allowed for, as determ<strong>in</strong>ed by the stress analysis.<br />

4.2.3 Vents and Valves<br />

In the majority of cases direct buried valves and vents will be <strong>in</strong>stalled <strong>in</strong> the heat<strong>in</strong>g distribution<br />

system. These will be operated through risers and valve boxes set at street level. Valve<br />

chambers will be designed and <strong>in</strong>stalled as necessary at strategic locations to house the larger<br />

isolation valves. Dra<strong>in</strong>s and vents will be <strong>in</strong>stalled either at the valve chambers or at separate<br />

purpose built chambers as necessary with<strong>in</strong> streets and sidewalks. The vaulted chambers may<br />

be constructed <strong>in</strong> place us<strong>in</strong>g re<strong>in</strong>forced precast concrete units or high density polymer<br />

concrete. All manholes will have person access for operation, ma<strong>in</strong>tenance and repair.