EntrEntr evista/evista/ InterInter viewview

EntrEntr evista/evista/ InterInter viewview

EntrEntr evista/evista/ InterInter viewview

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CENTRALES NUCLEARES/NUCLEAR POWER PLANTS<br />

FI<br />

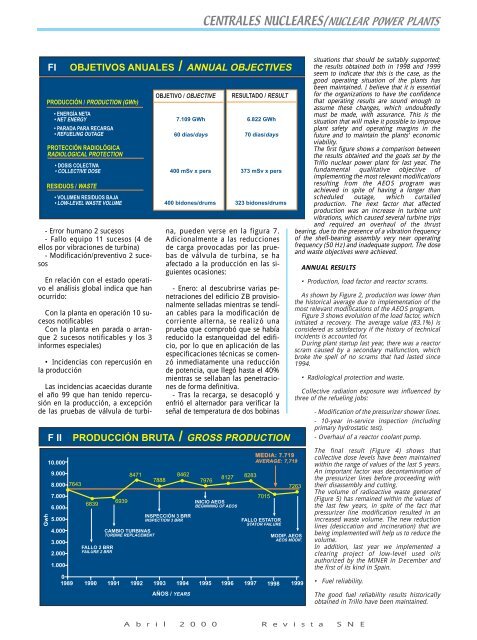

OBJETIVOS ANUALES / ANNUAL OBJECTIVES<br />

PRODUCCIÓN / PRODUCTION (GWh)<br />

• ENERGÍA NETA<br />

• NET ENERGY<br />

• PARADA PARA RECARGA<br />

• REFUELING OUTAGE<br />

- Error humano 2 sucesos<br />

- Fallo equipo 11 sucesos (4 de<br />

ellos por vibraciones de turbina)<br />

- Modificación/preventivo 2 sucesos<br />

En relación con el estado operativo<br />

el análisis global indica que han<br />

ocurrido:<br />

Con la planta en operación 10 sucesos<br />

notificables<br />

Con la planta en parada o arranque<br />

2 sucesos notificables y los 3<br />

informes especiales)<br />

• Incidencias con repercusión en<br />

la producción<br />

Gwh<br />

PROTECCIÓN RADIOLÓGICA<br />

RADIOLOGICAL PROTECTION<br />

• DOSIS COLECTIVA<br />

• COLLECTIVE DOSE<br />

RESIDUOS / WASTE<br />

• VOLUMEN RESIDUOS BAJA<br />

• LOW-LEVEL WASTE VOLUME<br />

F II<br />

10.000<br />

9.000<br />

OBJETIVO / OBJECTIVE RESULTADO / RESULT<br />

7.109 GWh<br />

60 días/days<br />

400 mSv x pers<br />

6.822 GWh<br />

70 días/days<br />

373 mSv x pers<br />

400 bidones/drums 323 bidones/drums<br />

Las incidencias acaecidas durante<br />

el año 99 que han tenido repercusión<br />

en la producción, a excepción<br />

de las pruebas de válvula de turbina,<br />

pueden verse en la figura 7.<br />

Adicionalmente a las reducciones<br />

de carga provocadas por las pruebas<br />

de válvula de turbina, se ha<br />

afectado a la producción en las siguientes<br />

ocasiones:<br />

- Enero: al descubrirse varias penetraciones<br />

del edificio ZB provisionalmente<br />

selladas mientras se tendían<br />

cables para la modificación de<br />

corriente alterna, se realizó una<br />

prueba que comprobó que se había<br />

reducido la estanqueidad del edificio,<br />

por lo que en aplicación de las<br />

especificaciones técnicas se comenzó<br />

inmediatamente una reducción<br />

de potencia, que llegó hasta el 40%<br />

mientras se sellaban las penetraciones<br />

de forma definitiva.<br />

- Tras la recarga, se desacopló y<br />

enfrió el alternador para verificar la<br />

señal de temperatura de dos bobinas<br />

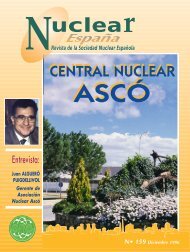

PRODUCCIÓN BRUTA / GROSS PRODUCTION<br />

8.000 7643<br />

7.000<br />

6839<br />

6.000<br />

5.000<br />

4.000<br />

3.000<br />

2.000<br />

1.000<br />

FALLO 2 BRR<br />

FAILURE 2 BRR<br />

6939<br />

8471<br />

CAMBIO TURBINAS<br />

TURBINE REPLACEMENT<br />

7888<br />

8462<br />

7976<br />

8127 8283<br />

INICIO AEOS<br />

BEGINNING OF AEOS<br />

INSPECCIÓN 3 BRR<br />

INSPECTION 3 BRR<br />

0<br />

1989 1990 1991 1992 1993 1994 1995 1996 1997<br />

AÑOS / YEARS<br />

MEDIA: 7.719<br />

AVERAGE: 7,719<br />

7015<br />

FALLO ESTATOR<br />

STATOR FAILURE<br />

1998<br />

situations that should be suitably supported;<br />

the results obtained both in 1998 and 1999<br />

seem to indicate that this is the case, as the<br />

good operating situation of the plants has<br />

been maintained. I believe that it is essential<br />

for the organizations to have the confidence<br />

that operating results are sound enough to<br />

assume these changes, which undoubtedly<br />

must be made, with assurance. This is the<br />

situation that will make it possible to improve<br />

plant safety and operating margins in the<br />

future and to maintain the plants’ economic<br />

viability.<br />

The first figure shows a comparison between<br />

the results obtained and the goals set by the<br />

Trillo nuclear power plant for last year. The<br />

fundamental qualitative objective of<br />

implementing the most relevant modifications<br />

resulting from the AEOS program was<br />

achieved in spite of having a longer than<br />

scheduled outage, which curtailed<br />

production. The next factor that affected<br />

production was an increase in turbine unit<br />

vibrations, which caused several turbine trips<br />

and required an overhaul of the thrust<br />

bearing, due to the presence of a vibration frequency<br />

of the shell-bearing assembly very near operating<br />

frequency (50 Hz) and inadequate support. The dose<br />

and waste objectives were achieved.<br />

ANNUAL RESULTS<br />

• Production, load factor and reactor scrams.<br />

As shown by Figure 2, production was lower than<br />

the historical average due to implementation of the<br />

most relevant modifications of the AEOS program.<br />

Figure 3 shows evolution of the load factor, which<br />

initiated a recovery. The average value (83.1%) is<br />

considered as satisfactory if the history of technical<br />

incidents is accounted for.<br />

During plant startup last year, there was a reactor<br />

scram caused by a secondary malfunction, which<br />

broke the spell of no scrams that had lasted since<br />

1994.<br />

• Radiological protection and waste.<br />

Collective radiation exposure was influenced by<br />

three of the refueling jobs:<br />

7263<br />

MODIF. AEOS<br />

AEOS MODIF.<br />

1999<br />

- Modification of the pressurizer shower lines.<br />

- 10-year in-service inspection (including<br />

primary hydrostatic test).<br />

- Overhaul of a reactor coolant pump.<br />

The final result (Figure 4) shows that<br />

collective dose levels have been maintained<br />

within the range of values of the last 5 years.<br />

An important factor was decontamination of<br />

the pressurizer lines before proceeding with<br />

their disassembly and cutting.<br />

The volume of radioactive waste generated<br />

(Figure 5) has remained within the values of<br />

the last few years, in spite of the fact that<br />

pressurizer line modification resulted in an<br />

increased waste volume. The new reduction<br />

lines (desiccation and incineration) that are<br />

being implemented will help us to reduce the<br />

volume.<br />

In addition, last year we implemented a<br />

clearing project of low-level used oils<br />

authorized by the MINER in December and<br />

the first of its kind in Spain.<br />

• Fuel reliability.<br />

The good fuel reliability results historically<br />

obtained in Trillo have been maintained.<br />

A b r i l 2 0 0 0<br />

R e v i s t a S N E