HC950 • HC950 SSP HC970 • HC970 SSP - Wagner

HC950 • HC950 SSP HC970 • HC970 SSP - Wagner

HC950 • HC950 SSP HC970 • HC970 SSP - Wagner

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

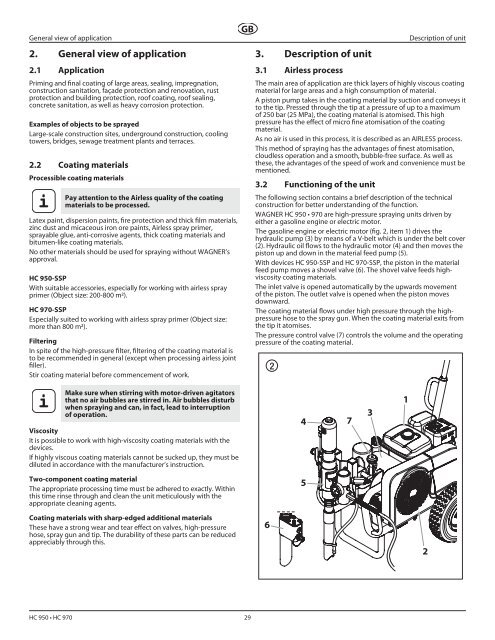

General view of application2. General view of application2.1 ApplicationPriming and final coating of large areas, sealing, impregnation,construction sanitation, façade protection and renovation, rustprotection and building protection, roof coating, roof sealing,concrete sanitation, as well as heavy corrosion protection.Examples of objects to be sprayedLarge-scale construction sites, underground construction, coolingtowers, bridges, sewage treatment plants and terraces.2.2 Coating materialsProcessible coating materialsiPay attention to the Airless quality of the coatingmaterials to be processed.Latex paint, dispersion paints, fire protection and thick film materials,zinc dust and micaceous iron ore paints, Airless spray primer,sprayable glue, anti-corrosive agents, thick coating materials andbitumen-like coating materials.No other materials should be used for spraying without WAGNER’sapproval.HC 950-<strong>SSP</strong>With suitable accessories, especially for working with airless sprayprimer (Object size: 200-800 m2).HC 970-<strong>SSP</strong>Especially suited to working with airless spray primer (Object size:more than 800 m2).FilteringIn spite of the high-pressure filter, filtering of the coating material isto be recommended in general (except when processing airless jointfiller).Stir coating material before commencement of work.GB3. Description of unitDescription of unit3.1 Airless processThe main area of application are thick layers of highly viscous coatingmaterial for large areas and a high consumption of material.A piston pump takes in the coating material by suction and conveys itto the tip. Pressed through the tip at a pressure of up to a maximumof 250 bar (25 MPa), the coating material is atomised. This highpressure has the effect of micro fine atomisation of the coatingmaterial.As no air is used in this process, it is described as an AIRLESS process.This method of spraying has the advantages of finest atomisation,cloudless operation and a smooth, bubble-free surface. As well asthese, the advantages of the speed of work and convenience must bementioned.3.2 Functioning of the unitThe following section contains a brief description of the technicalconstruction for better understanding of the function.WAGNER HC 950 <strong>•</strong> 970 are high-pressure spraying units driven byeither a gasoline engine or electric motor.The gasoline engine or electric motor (fig. 2, item 1) drives thehydraulic pump (3) by means of a V-belt which is under the belt cover(2). Hydraulic oil flows to the hydraulic motor (4) and then moves thepiston up and down in the material feed pump (5).With devices HC 950-<strong>SSP</strong> and HC 970-<strong>SSP</strong>, the piston in the materialfeed pump moves a shovel valve (6). The shovel valve feeds highviscositycoating materials.The inlet valve is opened automatically by the upwards movementof the piston. The outlet valve is opened when the piston movesdownward.The coating material flows under high pressure through the highpressurehose to the spray gun. When the coating material exits fromthe tip it atomises.The pressure control valve (7) controls the volume and the operatingpressure of the coating material.iMake sure when stirring with motor-driven agitatorsthat no air bubbles are stirred in. Air bubbles disturbwhen spraying and can, in fact, lead to interruptionof operation.ViscosityIt is possible to work with high-viscosity coating materials with thedevices.If highly viscous coating materials cannot be sucked up, they must bediluted in accordance with the manufacturer’s instruction.4731Two-component coating materialThe appropriate processing time must be adhered to exactly. Withinthis time rinse through and clean the unit meticulously with theappropriate cleaning agents.5Coating materials with sharp-edged additional materialsThese have a strong wear and tear effect on valves, high-pressurehose, spray gun and tip. The durability of these parts can be reducedappreciably through this.62HC 950 <strong>•</strong> HC 970 29