moleskine-ipo-report-04-03-2013-mediobanca

moleskine-ipo-report-04-03-2013-mediobanca

moleskine-ipo-report-04-03-2013-mediobanca

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Moleskine<br />

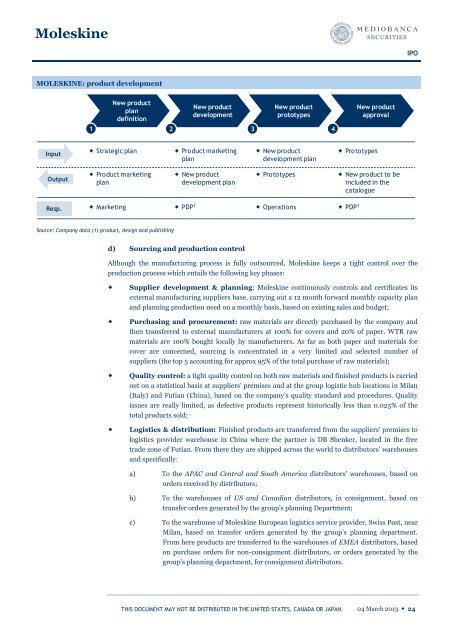

MOLESKINE: product development<br />

Input<br />

Output<br />

New product<br />

plan<br />

definition<br />

Strategic plan<br />

Product marketing<br />

plan<br />

New product<br />

development<br />

Product marketing<br />

plan<br />

New product<br />

development plan<br />

New product<br />

prototypes<br />

1 2 3 4<br />

New product<br />

development plan<br />

Resp. Marketing PDP 1 Operations PDP 1<br />

Source: Company data (1) product, design and publishing<br />

d) Sourcing and production control<br />

THIS DOCUMENT MAY NOT BE DISTRIBUTED IN THE UNITED STATES, CANADA OR JAPAN.<br />

New product<br />

approval<br />

Prototypes<br />

Prototypes New product to be<br />

included in the<br />

catalogue<br />

Although the manufacturing process is fully outsourced, Moleskine keeps a tight control over the<br />

production process which entails the following key phases:<br />

Supplier development & planning: Moleskine continuously controls and certificates its<br />

external manufacturing suppliers base, carrying out a 12 month forward monthly capacity plan<br />

and planning production need on a monthly basis, based on existing sales and budget;<br />

Purchasing and procurement: raw materials are directly purchased by the company and<br />

then transferred to external manufacturers at 100% for covers and 20% of paper. WTR raw<br />

materials are 100% bought locally by manufacturers. As far as both paper and materials for<br />

cover are concerned, sourcing is concentrated in a very limited and selected number of<br />

suppliers (the top 5 accounting for approx 95% of the total purchase of raw materials);<br />

Quality control: a tight quality control on both raw materials and finished products is carried<br />

out on a statistical basis at suppliers’ premises and at the group logistic hub locations in Milan<br />

(Italy) and Futian (China), based on the company’s quality standard and procedures. Quality<br />

issues are really limited, as defective products represent historically less than 0.025% of the<br />

total products sold;<br />

Logistics & distribution: Finished products are transferred from the suppliers’ premises to<br />

logistics provider warehouse in China where the partner is DB Shenker, located in the free<br />

trade zone of Futian. From there they are shipped across the world to distributors’ warehouses<br />

and specifically:<br />

a) To the APAC and Central and South America distributors’ warehouses, based on<br />

orders received by distributors;<br />

b) To the warehouses of US and Canadian distributors, in consignment, based on<br />

transfer orders generated by the group’s planning Department;<br />

c) To the warehouse of Moleskine European logistics service provider, Swiss Post, near<br />

Milan, based on transfer orders generated by the group’s planning department.<br />

From here products are transferred to the warehouses of EMEA distributors, based<br />

on purchase orders for non-consignment distributors, or orders generated by the<br />

group’s planning department, for consignment distributors.<br />

IPO<br />

<strong>04</strong> March <strong>2013</strong> ◆ 24