Ergonomics - Atlas Copco

Ergonomics - Atlas Copco

Ergonomics - Atlas Copco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

82<br />

Comments for different<br />

tool types<br />

In this section the different types of tools<br />

are discussed. A tool can be used in an infi-<br />

nite number of different ways and the load<br />

on the operator is unique for each situation.<br />

The discussion below can therefore only be<br />

used as a rough guide, giving an indication<br />

of what to think about when the load on the<br />

operator is estimated.<br />

Normally, more powerful tools require<br />

more force. This can be taken into account<br />

choosing a force within the spread given in<br />

the table.<br />

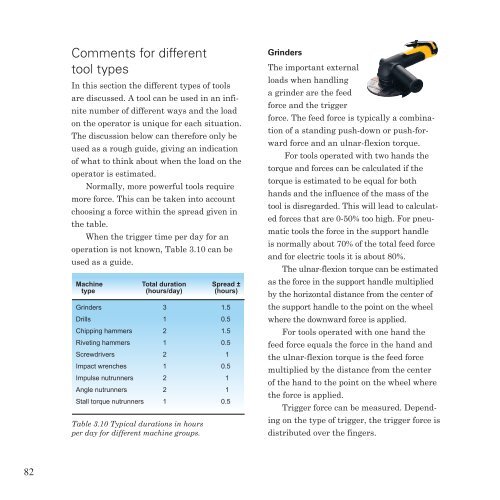

When the trigger time per day for an<br />

operation is not known, Table 3.10 can be<br />

used as a guide.<br />

Machine Total duration Spread ±<br />

type (hours/day) (hours)<br />

Grinders 3 1.5<br />

Drills 1 0.5<br />

Chipping hammers 2 1.5<br />

Riveting hammers 1 0.5<br />

Screwdrivers 2 1<br />

Impact wrenches 1 0.5<br />

Impulse nutrunners 2 1<br />

Angle nutrunners 2 1<br />

Stall torque nutrunners 1 0.5<br />

Table 3.10 Typical durations in hours<br />

per day for different machine groups.<br />

Grinders<br />

The important external<br />

loads when handling<br />

a grinder are the feed<br />

force and the trigger<br />

force. The feed force is typically a combina-<br />

tion of a standing push-down or push-for-<br />

ward force and an ulnar-flexion torque.<br />

For tools operated with two hands the<br />

torque and forces can be calculated if the<br />

torque is estimated to be equal for both<br />

hands and the influence of the mass of the<br />

tool is disregarded. This will lead to calculat-<br />

ed forces that are 0-50% too high. For pneu-<br />

matic tools the force in the support handle<br />

is normally about 70% of the total feed force<br />

and for electric tools it is about 80%.<br />

The ulnar-flexion torque can be estimated<br />

as the force in the support handle multiplied<br />

by the horizontal distance from the center of<br />

the support handle to the point on the wheel<br />

where the downward force is applied.<br />

For tools operated with one hand the<br />

feed force equals the force in the hand and<br />

the ulnar-flexion torque is the feed force<br />

multiplied by the distance from the center<br />

of the hand to the point on the wheel where<br />

the force is applied.<br />

Trigger force can be measured. Depend-<br />

ing on the type of trigger, the trigger force is<br />

distributed over the fingers.