analysis of a pilot-scale anaerobic baffled reactor treating domestic ...

analysis of a pilot-scale anaerobic baffled reactor treating domestic ...

analysis of a pilot-scale anaerobic baffled reactor treating domestic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The original objective to develop a dynamic mathematical model <strong>of</strong> biochemical processes for the<br />

purposes <strong>of</strong> designing ABR systems was over-optimistic, given the quality <strong>of</strong> the experimental data<br />

available. These data were mined for design information about process limitations (upflow velocity in<br />

this case) and for CH4 and sludge production estimates. More sophisticated design tools can only be<br />

developed with the assistance <strong>of</strong> additional experimental data describing the relationships between<br />

observed sludge accumulation or retention and applied upflow velocity, alkalinity and organic loading<br />

rate.<br />

Nevertheless, a model was developed using the WEST 1 platform to identify what further information<br />

would be required to build a biochemical model for design purposes.<br />

6.5.1 Model construction<br />

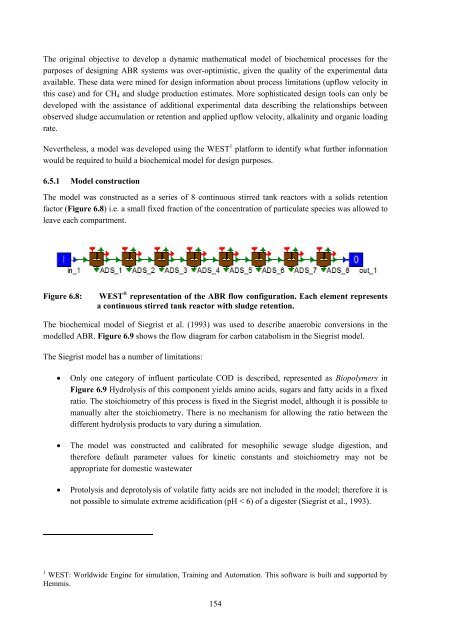

The model was constructed as a series <strong>of</strong> 8 continuous stirred tank <strong>reactor</strong>s with a solids retention<br />

factor (Figure 6.8) i.e. a small fixed fraction <strong>of</strong> the concentration <strong>of</strong> particulate species was allowed to<br />

leave each compartment.<br />

Figure 6.8: WEST ® representation <strong>of</strong> the ABR flow configuration. Each element represents<br />

a continuous stirred tank <strong>reactor</strong> with sludge retention.<br />

The biochemical model <strong>of</strong> Siegrist et al. (1993) was used to describe <strong>anaerobic</strong> conversions in the<br />

modelled ABR. Figure 6.9 shows the flow diagram for carbon catabolism in the Siegrist model.<br />

The Siegrist model has a number <strong>of</strong> limitations:<br />

• Only one category <strong>of</strong> influent particulate COD is described, represented as Biopolymers in<br />

Figure 6.9 Hydrolysis <strong>of</strong> this component yields amino acids, sugars and fatty acids in a fixed<br />

ratio. The stoichiometry <strong>of</strong> this process is fixed in the Siegrist model, although it is possible to<br />

manually alter the stoichiometry. There is no mechanism for allowing the ratio between the<br />

different hydrolysis products to vary during a simulation.<br />

• The model was constructed and calibrated for mesophilic sewage sludge digestion, and<br />

therefore default parameter values for kinetic constants and stoichiometry may not be<br />

appropriate for <strong>domestic</strong> wastewater<br />

• Protolysis and deprotolysis <strong>of</strong> volatile fatty acids are not included in the model; therefore it is<br />

not possible to simulate extreme acidification (pH < 6) <strong>of</strong> a digester (Siegrist et al., 1993).<br />

1<br />

WEST: Worldwide Engine for simulation, Training and Automation. This s<strong>of</strong>tware is built and supported by<br />

Hemmis.<br />

154