analysis of a pilot-scale anaerobic baffled reactor treating domestic ...

analysis of a pilot-scale anaerobic baffled reactor treating domestic ...

analysis of a pilot-scale anaerobic baffled reactor treating domestic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

introduction to characterisation <strong>of</strong> <strong>reactor</strong> hydrodynamics and how <strong>reactor</strong> hydrodynamics impact on<br />

<strong>anaerobic</strong> digestion processes.<br />

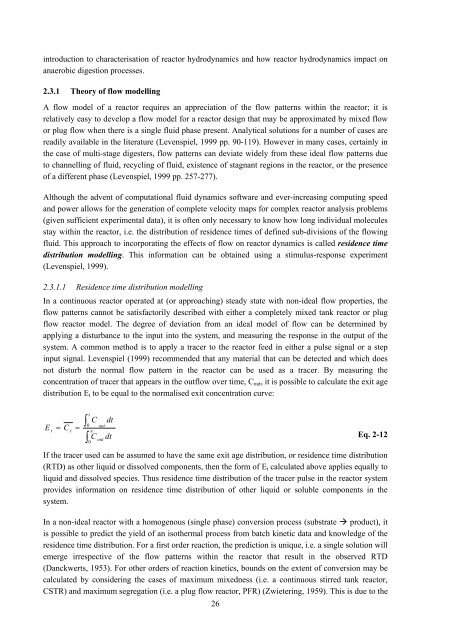

2.3.1 Theory <strong>of</strong> flow modelling<br />

A flow model <strong>of</strong> a <strong>reactor</strong> requires an appreciation <strong>of</strong> the flow patterns within the <strong>reactor</strong>; it is<br />

relatively easy to develop a flow model for a <strong>reactor</strong> design that may be approximated by mixed flow<br />

or plug flow when there is a single fluid phase present. Analytical solutions for a number <strong>of</strong> cases are<br />

readily available in the literature (Levenspiel, 1999 pp. 90-119). However in many cases, certainly in<br />

the case <strong>of</strong> multi-stage digesters, flow patterns can deviate widely from these ideal flow patterns due<br />

to channelling <strong>of</strong> fluid, recycling <strong>of</strong> fluid, existence <strong>of</strong> stagnant regions in the <strong>reactor</strong>, or the presence<br />

<strong>of</strong> a different phase (Levenspiel, 1999 pp. 257-277).<br />

Although the advent <strong>of</strong> computational fluid dynamics s<strong>of</strong>tware and ever-increasing computing speed<br />

and power allows for the generation <strong>of</strong> complete velocity maps for complex <strong>reactor</strong> <strong>analysis</strong> problems<br />

(given sufficient experimental data), it is <strong>of</strong>ten only necessary to know how long individual molecules<br />

stay within the <strong>reactor</strong>, i.e. the distribution <strong>of</strong> residence times <strong>of</strong> defined sub-divisions <strong>of</strong> the flowing<br />

fluid. This approach to incorporating the effects <strong>of</strong> flow on <strong>reactor</strong> dynamics is called residence time<br />

distribution modelling. This information can be obtained using a stimulus-response experiment<br />

(Levenspiel, 1999).<br />

2.3.1.1 Residence time distribution modelling<br />

In a continuous <strong>reactor</strong> operated at (or approaching) steady state with non-ideal flow properties, the<br />

flow patterns cannot be satisfactorily described with either a completely mixed tank <strong>reactor</strong> or plug<br />

flow <strong>reactor</strong> model. The degree <strong>of</strong> deviation from an ideal model <strong>of</strong> flow can be determined by<br />

applying a disturbance to the input into the system, and measuring the response in the output <strong>of</strong> the<br />

system. A common method is to apply a tracer to the <strong>reactor</strong> feed in either a pulse signal or a step<br />

input signal. Levenspiel (1999) recommended that any material that can be detected and which does<br />

not disturb the normal flow pattern in the <strong>reactor</strong> can be used as a tracer. By measuring the<br />

concentration <strong>of</strong> tracer that appears in the outflow over time, Cout, it is possible to calculate the exit age<br />

distribution Et to be equal to the normalised exit concentration curve:<br />

E<br />

t<br />

= C<br />

t<br />

=<br />

t<br />

∫0 ∞<br />

∫<br />

0<br />

C<br />

C<br />

out<br />

out<br />

dt<br />

dt<br />

26<br />

Eq. 2-12<br />

If the tracer used can be assumed to have the same exit age distribution, or residence time distribution<br />

(RTD) as other liquid or dissolved components, then the form <strong>of</strong> Et calculated above applies equally to<br />

liquid and dissolved species. Thus residence time distribution <strong>of</strong> the tracer pulse in the <strong>reactor</strong> system<br />

provides information on residence time distribution <strong>of</strong> other liquid or soluble components in the<br />

system.<br />

In a non-ideal <strong>reactor</strong> with a homogenous (single phase) conversion process (substrate product), it<br />

is possible to predict the yield <strong>of</strong> an isothermal process from batch kinetic data and knowledge <strong>of</strong> the<br />

residence time distribution. For a first order reaction, the prediction is unique, i.e. a single solution will<br />

emerge irrespective <strong>of</strong> the flow patterns within the <strong>reactor</strong> that result in the observed RTD<br />

(Danckwerts, 1953). For other orders <strong>of</strong> reaction kinetics, bounds on the extent <strong>of</strong> conversion may be<br />

calculated by considering the cases <strong>of</strong> maximum mixedness (i.e. a continuous stirred tank <strong>reactor</strong>,<br />

CSTR) and maximum segregation (i.e. a plug flow <strong>reactor</strong>, PFR) (Zwietering, 1959). This is due to the