analysis of a pilot-scale anaerobic baffled reactor treating domestic ...

analysis of a pilot-scale anaerobic baffled reactor treating domestic ...

analysis of a pilot-scale anaerobic baffled reactor treating domestic ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2.5 THE ANAEROBIC BAFFLED REACTOR<br />

The <strong>anaerobic</strong> <strong>baffled</strong> <strong>reactor</strong> is a high rate <strong>anaerobic</strong> digester that has been used to pre-treat or codigest<br />

high strength or toxic industrial effluents. Its application in the treatment <strong>of</strong> low-strength<br />

wastewaters has been tested on a laboratory-<strong>scale</strong> and in a number <strong>of</strong> full-<strong>scale</strong> applications for the<br />

primary treatment <strong>of</strong> <strong>domestic</strong> wastewater. A modified ABR forms the central unit <strong>of</strong> the DEWATS<br />

(DEcentralised WAstewater Treatment Systems) plant that has been implemented to provide low cost<br />

<strong>domestic</strong> wastewater treatment in low income communities in South-East Asia, India, China and<br />

Africa (Sasse, 1998; BORDA, 2008).<br />

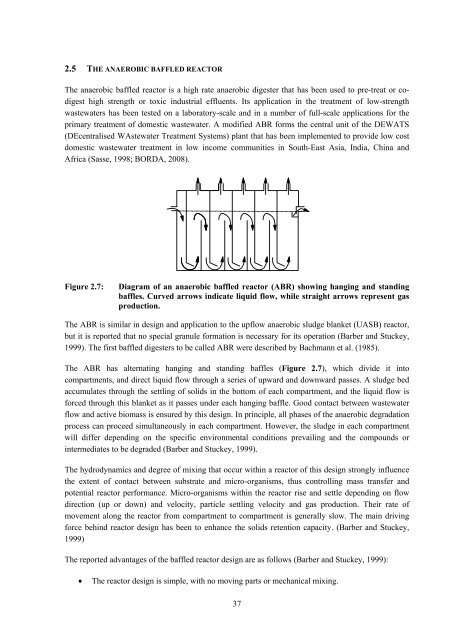

Figure 2.7: Diagram <strong>of</strong> an <strong>anaerobic</strong> <strong>baffled</strong> <strong>reactor</strong> (ABR) showing hanging and standing<br />

baffles. Curved arrows indicate liquid flow, while straight arrows represent gas<br />

production.<br />

The ABR is similar in design and application to the upflow <strong>anaerobic</strong> sludge blanket (UASB) <strong>reactor</strong>,<br />

but it is reported that no special granule formation is necessary for its operation (Barber and Stuckey,<br />

1999). The first <strong>baffled</strong> digesters to be called ABR were described by Bachmann et al. (1985).<br />

The ABR has alternating hanging and standing baffles (Figure 2.7), which divide it into<br />

compartments, and direct liquid flow through a series <strong>of</strong> upward and downward passes. A sludge bed<br />

accumulates through the settling <strong>of</strong> solids in the bottom <strong>of</strong> each compartment, and the liquid flow is<br />

forced through this blanket as it passes under each hanging baffle. Good contact between wastewater<br />

flow and active biomass is ensured by this design. In principle, all phases <strong>of</strong> the <strong>anaerobic</strong> degradation<br />

process can proceed simultaneously in each compartment. However, the sludge in each compartment<br />

will differ depending on the specific environmental conditions prevailing and the compounds or<br />

intermediates to be degraded (Barber and Stuckey, 1999).<br />

The hydrodynamics and degree <strong>of</strong> mixing that occur within a <strong>reactor</strong> <strong>of</strong> this design strongly influence<br />

the extent <strong>of</strong> contact between substrate and micro-organisms, thus controlling mass transfer and<br />

potential <strong>reactor</strong> performance. Micro-organisms within the <strong>reactor</strong> rise and settle depending on flow<br />

direction (up or down) and velocity, particle settling velocity and gas production. Their rate <strong>of</strong><br />

movement along the <strong>reactor</strong> from compartment to compartment is generally slow. The main driving<br />

force behind <strong>reactor</strong> design has been to enhance the solids retention capacity. (Barber and Stuckey,<br />

1999)<br />

The reported advantages <strong>of</strong> the <strong>baffled</strong> <strong>reactor</strong> design are as follows (Barber and Stuckey, 1999):<br />

• The <strong>reactor</strong> design is simple, with no moving parts or mechanical mixing.<br />

37