Special Issue; Products for Industrial Machinery - NTN

Special Issue; Products for Industrial Machinery - NTN

Special Issue; Products for Industrial Machinery - NTN

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>NTN</strong> TECHNICAL REVIEW No.742006<br />

CCO22COBoudouard reaction<br />

a c <br />

K 1 P CO2<br />

K exp<br />

P CO<br />

2<br />

<br />

G<br />

<br />

T<br />

RT<br />

G T 172500175.6T<br />

where ac = carbon activity; K1 = equilibrium<br />

constant; R = gas constant (8.31441 J/(mol-K)); T =<br />

absolute temperature (˚K); G** = standard free<br />

energy of <strong>for</strong>mation; 5) PCO = CO partial pressure and<br />

PCO2 = CO2 partial pressure (atm).<br />

Because of the definition of carbon activity, ac1 is<br />

not possible. However, as shown by expression (1), a<br />

calculated value of ac can be greater than 1 in certain<br />

situations, and a carbonitriding process can take<br />

place. 6) To investigate the effect of such an<br />

atmosphere, expression (1) was redefined as (1’), and<br />

this expression was used as a parameter <strong>for</strong> the<br />

experiment.<br />

P CO<br />

2<br />

1<br />

2<br />

3<br />

a c 1'<br />

K 1 P CO2<br />

where, when ac*1, ac* = ac (carbon activity), and<br />

when ac*1, ac* is a variant expressed by expression<br />

(1’).<br />

2.4 Experimental Parameters<br />

2.4.1 Effects of partial pressure of<br />

undecomposed NH3 and carbon activity<br />

on carbonitriding processes<br />

Within every set of parameters in these experiments,<br />

temperature was maintained at 850˚C and furnace<br />

pressure was held at 1.03 atm (1 atm = 1.013 x 10 5<br />

Pa). At the same time, the total surface area of the<br />

test pieces was the same. Four types of test<br />

parameters were varied: the carbon activity ac*,<br />

carbonitriding process duration, base gas flow rates<br />

and partial pressure of undecomposed NH3. The ac*<br />

was held at one of six levels ranging between 0.78<br />

and 1.08 and the carbonitriding process duration<br />

varied from 1,800 to 18,000 seconds. The base gas<br />

flow rate ranged from 6 to 20 L/min and the<br />

undecomposed NH3 varied from 0.36 to 3.4 x 10 -3 atm.<br />

Incidentally, the base gas feeder shown in Fig. 2 was<br />

not used <strong>for</strong> these experiments. Instead, the base gas<br />

used was an ordinary endothermic modified gas<br />

derived from propane.<br />

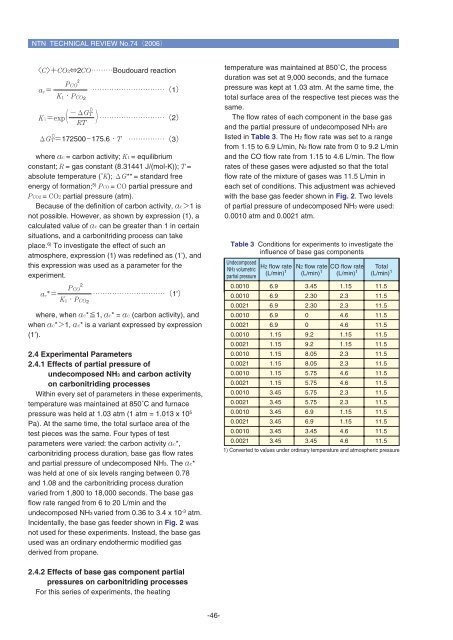

temperature was maintained at 850˚C, the process<br />

duration was set at 9,000 seconds, and the furnace<br />

pressure was kept at 1.03 atm. At the same time, the<br />

total surface area of the respective test pieces was the<br />

same.<br />

The flow rates of each component in the base gas<br />

and the partial pressure of undecomposed NH3 are<br />

listed in Table 3. The H2 flow rate was set to a range<br />

from 1.15 to 6.9 L/min, N2 flow rate from 0 to 9.2 L/min<br />

and the CO flow rate from 1.15 to 4.6 L/min. The flow<br />

rates of these gases were adjusted so that the total<br />

flow rate of the mixture of gases was 11.5 L/min in<br />

each set of conditions. This adjustment was achieved<br />

with the base gas feeder shown in Fig. 2. Two levels<br />

of partial pressure of undecomposed NH3 were used:<br />

0.0010 atm and 0.0021 atm.<br />

Table 3 Conditions <strong>for</strong> experiments to investigate the<br />

influence of base gas components<br />

Undecomposed<br />

NH3 volumetric<br />

partial pressure<br />

H2 flow rate<br />

(L/min) 1<br />

N2 flow rate<br />

(L/min) 1<br />

CO flow rate<br />

(L/min) 1<br />

Total<br />

(L/min) 1<br />

0.0010 6.9 3.45 1.15 11.5<br />

0.0010 6.9 2.30 2.3 11.5<br />

0.0021 6.9 2.30 2.3 11.5<br />

0.0010 6.9 0 4.6 11.5<br />

0.0021 6.9 0 4.6 11.5<br />

0.0010 1.15 9.2 1.15 11.5<br />

0.0021 1.15 9.2 1.15 11.5<br />

0.0010 1.15 8.05 2.3 11.5<br />

0.0021 1.15 8.05 2.3 11.5<br />

0.0010 1.15 5.75 4.6 11.5<br />

0.0021 1.15 5.75 4.6 11.5<br />

0.0010 3.45 5.75 2.3 11.5<br />

0.0021 3.45 5.75 2.3 11.5<br />

0.0010 3.45 6.9 1.15 11.5<br />

0.0021 3.45 6.9 1.15 11.5<br />

0.0010 3.45 3.45 4.6 11.5<br />

0.0021 3.45 3.45 4.6 11.5<br />

1) Converted to values under ordinary temperature and atmospheric pressure<br />

2.4.2 Effects of base gas component partial<br />

pressures on carbonitriding processes<br />

For this series of experiments, the heating<br />

-46-

![[New Product] Unit Products for Office Equipment - NTN](https://img.yumpu.com/27154451/1/184x260/new-product-unit-products-for-office-equipment-ntn.jpg?quality=85)

![[New Product] Development of Oil-impregnated Sintered ... - NTN](https://img.yumpu.com/27154427/1/184x260/new-product-development-of-oil-impregnated-sintered-ntn.jpg?quality=85)