Special Issue; Products for Industrial Machinery - NTN

Special Issue; Products for Industrial Machinery - NTN

Special Issue; Products for Industrial Machinery - NTN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>NTN</strong> TECHNICAL REVIEW No.742006<br />

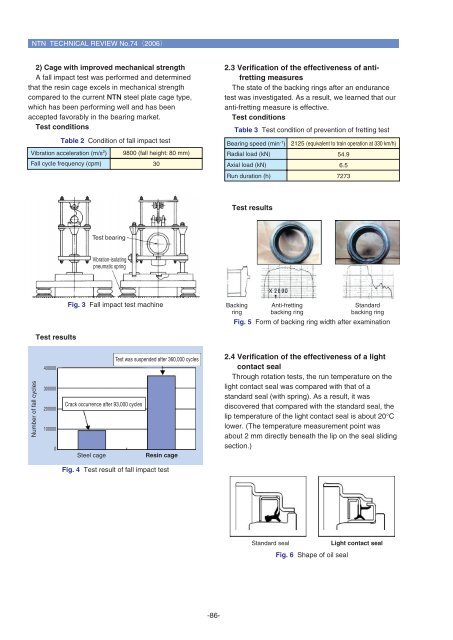

2) Cage with improved mechanical strength<br />

A fall impact test was per<strong>for</strong>med and determined<br />

that the resin cage excels in mechanical strength<br />

compared to the current <strong>NTN</strong> steel plate cage type,<br />

which has been per<strong>for</strong>ming well and has been<br />

accepted favorably in the bearing market.<br />

Test conditions<br />

Table 2 Condition of fall impact test<br />

Vibration acceleration (m/s 2 )<br />

Fall cycle frequency (cpm)<br />

9800 (fall height: 80 mm)<br />

30<br />

2.3 Verification of the effectiveness of antifretting<br />

measures<br />

The state of the backing rings after an endurance<br />

test was investigated. As a result, we learned that our<br />

anti-fretting measure is effective.<br />

Test conditions<br />

Table 3 Test condition of prevention of fretting test<br />

Bearing speed (min -1 )<br />

Radial load (kN)<br />

Axial load (kN)<br />

Run duration (h)<br />

2125 (equivalent to train operation at 330 km/h)<br />

54.9<br />

6.5<br />

7273<br />

Test results<br />

Test bearing<br />

Vibration-isolating<br />

pneumatic spring<br />

Fig. 3 Fall impact test machine<br />

Backing<br />

ring<br />

Anti-fretting<br />

backing ring<br />

Standard<br />

backing ring<br />

Fig. 5 Form of backing ring width after examination<br />

Test results<br />

Number of fall cycles<br />

400000<br />

300000<br />

200000<br />

100000<br />

0<br />

Test was suspended after 360,000 cycles<br />

Crack occurrence after 93,000 cycles<br />

Steel cage<br />

Resin cage<br />

2.4 Verification of the effectiveness of a light<br />

contact seal<br />

Through rotation tests, the run temperature on the<br />

light contact seal was compared with that of a<br />

standard seal (with spring). As a result, it was<br />

discovered that compared with the standard seal, the<br />

lip temperature of the light contact seal is about 20°C<br />

lower. (The temperature measurement point was<br />

about 2 mm directly beneath the lip on the seal sliding<br />

section.)<br />

Fig. 4 Test result of fall impact test<br />

Standard seal<br />

Light contact seal<br />

Fig. 6 Shape of oil seal<br />

-86-

![[New Product] Unit Products for Office Equipment - NTN](https://img.yumpu.com/27154451/1/184x260/new-product-unit-products-for-office-equipment-ntn.jpg?quality=85)

![[New Product] Development of Oil-impregnated Sintered ... - NTN](https://img.yumpu.com/27154427/1/184x260/new-product-development-of-oil-impregnated-sintered-ntn.jpg?quality=85)