Special Issue; Products for Industrial Machinery - NTN

Special Issue; Products for Industrial Machinery - NTN

Special Issue; Products for Industrial Machinery - NTN

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Ultra-Clean Bearing <strong>for</strong> Clean Environments<br />

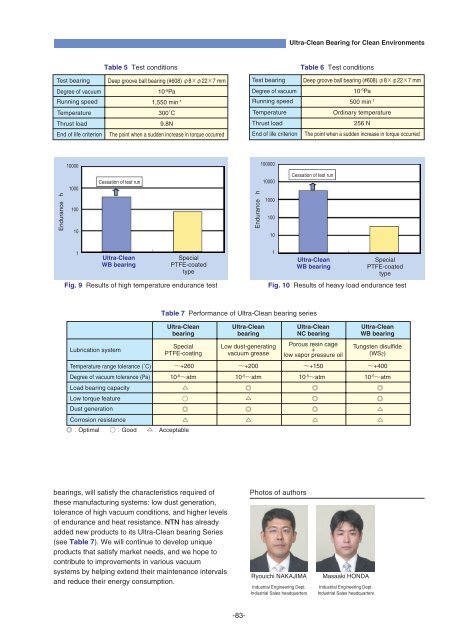

Table 5 Test conditions<br />

Table 6 Test conditions<br />

Test bearing<br />

Deep groove ball bearing (#608) 8227 mm<br />

Test bearing<br />

Deep groove ball bearing (#608) 8227 mm<br />

Degree of vacuum<br />

Running speed<br />

10 -5 Pa<br />

1,550 min -1<br />

Degree of vacuum<br />

Running speed<br />

10 -5 Pa<br />

500 min -1<br />

Temperature<br />

300˚C<br />

Temperature<br />

Ordinary temperature<br />

Thrust load<br />

9.8N<br />

Thrust load<br />

256 N<br />

End of life criterion<br />

The point when a sudden increase in torque occurred<br />

End of life criterion<br />

The point when a sudden increase in torque occurred<br />

10000<br />

100000<br />

Endurance h<br />

1000<br />

100<br />

10<br />

Cessation of test run<br />

Endurance h<br />

10000<br />

1000<br />

100<br />

10<br />

Cessation of test run<br />

1<br />

Ultra-Clean<br />

WB bearing<br />

<strong>Special</strong><br />

PTFE-coated<br />

type<br />

Fig. 9 Results of high temperature endurance test<br />

1<br />

Ultra-Clean<br />

WB bearing<br />

<strong>Special</strong><br />

PTFE-coated<br />

type<br />

Fig. 10 Results of heavy load endurance test<br />

Lubrication system<br />

Temperature range tolerance (˚C)<br />

Degree of vacuum tolerance (Pa)<br />

Load bearing capacity<br />

Low torque feature<br />

Dust generation<br />

Corrosion resistance<br />

<br />

Table 7 Per<strong>for</strong>mance of Ultra-Clean bearing series<br />

Ultra-Clean<br />

bearing<br />

<strong>Special</strong><br />

PTFE-coating<br />

Optimal Good Acceptable<br />

Ultra-Clean<br />

bearing<br />

Low dust-generating<br />

vacuum grease<br />

Ultra-Clean<br />

NC bearing<br />

Porous resin cage<br />

+<br />

low vapor pressure oil<br />

Ultra-Clean<br />

WB bearing<br />

Tungsten disulfide<br />

(WS2)<br />

+260 +200 +150 +400<br />

10 -6 atm 10 -5 atm 10 -5 atm 10 -5 atm<br />

<br />

<br />

<br />

<br />

bearings, will satisfy the characteristics required of<br />

these manufacturing systems: low dust generation,<br />

tolerance of high vacuum conditions, and higher levels<br />

of endurance and heat resistance. <strong>NTN</strong> has already<br />

added new products to its Ultra-Clean bearing Series<br />

(see Table 7). We will continue to develop unique<br />

products that satisfy market needs, and we hope to<br />

contribute to improvements in various vacuum<br />

systems by helping extend their maintenance intervals<br />

and reduce their energy consumption.<br />

Photos of authors<br />

Ryouichi NAKAJIMA<br />

<strong>Industrial</strong> Engineering Dept.<br />

<strong>Industrial</strong> Sales headquarters<br />

Masaaki HONDA<br />

<strong>Industrial</strong> Engineering Dept.<br />

<strong>Industrial</strong> Sales headquarters<br />

-83-

![[New Product] Unit Products for Office Equipment - NTN](https://img.yumpu.com/27154451/1/184x260/new-product-unit-products-for-office-equipment-ntn.jpg?quality=85)

![[New Product] Development of Oil-impregnated Sintered ... - NTN](https://img.yumpu.com/27154427/1/184x260/new-product-development-of-oil-impregnated-sintered-ntn.jpg?quality=85)