Special Issue; Products for Industrial Machinery - NTN

Special Issue; Products for Industrial Machinery - NTN

Special Issue; Products for Industrial Machinery - NTN

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Development of New RCT Bearing <strong>for</strong> Axleboxes and Insulated Bearing with Shields<br />

Test conditions<br />

Table 4 Test condition of light contact seal<br />

Radial load (kN)<br />

Axial load (kN)<br />

Bearing speed (min -1 )<br />

Run pattern<br />

Test results<br />

Standard<br />

seal<br />

Bearing speed (rpm)<br />

Train speed (km/h)<br />

Radial load (kN)<br />

Axial load (kN)<br />

Cooling air speed (m/s)<br />

Run duration (h)<br />

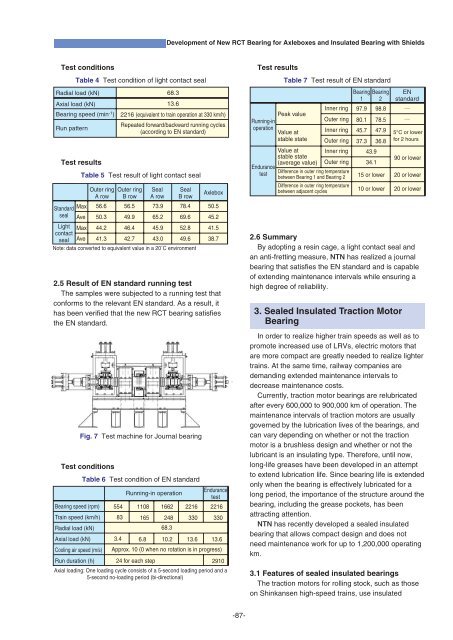

Fig. 7 Test machine <strong>for</strong> Journal bearing<br />

Table 6 Test condition of EN standard<br />

Running-in operation<br />

554 1108<br />

83 165<br />

3.4<br />

68.3<br />

13.6<br />

2216 (equivalent to train operation at 330 km/h)<br />

Repeated <strong>for</strong>ward/backward running cycles<br />

(according to EN standard)<br />

Table 5 Test result of light contact seal<br />

Max<br />

Ave<br />

Outer ring<br />

A row<br />

Light Max 44.2 46.4 45.9 52.8 41.5<br />

contact<br />

seal Ave 41.3 42.7 43.0 49.6 38.7<br />

Note: data converted to equivalent value in a 20˚C environment<br />

2.5 Result of EN standard running test<br />

The samples were subjected to a running test that<br />

con<strong>for</strong>ms to the relevant EN standard. As a result, it<br />

has been verified that the new RCT bearing satisfies<br />

the EN standard.<br />

Test conditions<br />

Outer ring<br />

B row<br />

1662<br />

248<br />

68.3<br />

2216<br />

330<br />

Endurance<br />

test<br />

2216<br />

330<br />

6.8 10.2 13.6 13.6<br />

Approx. 10 (0 when no rotation is in progress)<br />

24 <strong>for</strong> each step<br />

Seal<br />

A row<br />

Seal<br />

B row<br />

Axlebox<br />

56.6 56.5 73.9 78.4 50.5<br />

50.3 49.9 65.2 69.6 45.2<br />

2910<br />

Axial loading: One loading cycle consists of a 5-second loading period and a<br />

5-second no-loading period (bi-directional)<br />

Test results<br />

Running-in<br />

operation<br />

Endurance<br />

test<br />

Table 7 Test result of EN standard<br />

Peak value<br />

Value at<br />

stable state<br />

Value at<br />

stable state<br />

(average value)<br />

Inner ring<br />

Outer ring<br />

Inner ring<br />

Outer ring<br />

Inner ring<br />

Outer ring<br />

Difference in outer ring temperature<br />

between Bearing 1 and Bearing 2<br />

Difference in outer ring temperature<br />

between adjacent cycles<br />

Bearing<br />

1<br />

Bearing<br />

2<br />

EN<br />

standard<br />

97.9 98.8 <br />

80.1 78.5 <br />

45.7 47.9 5°C or lower<br />

37.3 36.8 <strong>for</strong> 2 hours<br />

43.9<br />

34.1<br />

15 or lower<br />

90 or lower<br />

20 or lower<br />

10 or lower<br />

20 or lower<br />

2.6 Summary<br />

By adopting a resin cage, a light contact seal and<br />

an anti-fretting measure, <strong>NTN</strong> has realized a journal<br />

bearing that satisfies the EN standard and is capable<br />

of extending maintenance intervals while ensuring a<br />

high degree of reliability.<br />

3. Sealed Insulated Traction Motor<br />

Bearing<br />

In order to realize higher train speeds as well as to<br />

promote increased use of LRVs, electric motors that<br />

are more compact are greatly needed to realize lighter<br />

trains. At the same time, railway companies are<br />

demanding extended maintenance intervals to<br />

decrease maintenance costs.<br />

Currently, traction motor bearings are relubricated<br />

after every 600,000 to 900,000 km of operation. The<br />

maintenance intervals of traction motors are usually<br />

governed by the lubrication lives of the bearings, and<br />

can vary depending on whether or not the traction<br />

motor is a brushless design and whether or not the<br />

lubricant is an insulating type. There<strong>for</strong>e, until now,<br />

long-life greases have been developed in an attempt<br />

to extend lubrication life. Since bearing life is extended<br />

only when the bearing is effectively lubricated <strong>for</strong> a<br />

long period, the importance of the structure around the<br />

bearing, including the grease pockets, has been<br />

attracting attention.<br />

<strong>NTN</strong> has recently developed a sealed insulated<br />

bearing that allows compact design and does not<br />

need maintenance work <strong>for</strong> up to 1,200,000 operating<br />

km.<br />

3.1 Features of sealed insulated bearings<br />

The traction motors <strong>for</strong> rolling stock, such as those<br />

on Shinkansen high-speed trains, use insulated<br />

-87-

![[New Product] Unit Products for Office Equipment - NTN](https://img.yumpu.com/27154451/1/184x260/new-product-unit-products-for-office-equipment-ntn.jpg?quality=85)

![[New Product] Development of Oil-impregnated Sintered ... - NTN](https://img.yumpu.com/27154427/1/184x260/new-product-development-of-oil-impregnated-sintered-ntn.jpg?quality=85)