specification for subdivision construction of road works and drainage

specification for subdivision construction of road works and drainage

specification for subdivision construction of road works and drainage

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

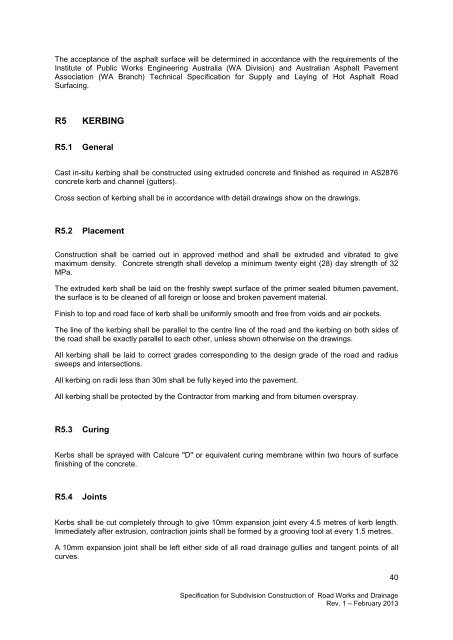

The acceptance <strong>of</strong> the asphalt surface will be determined in accordance with the requirements <strong>of</strong> the<br />

Institute <strong>of</strong> Public Works Engineering Australia (WA Division) <strong>and</strong> Australian Asphalt Pavement<br />

Association (WA Branch) Technical Specification <strong>for</strong> Supply <strong>and</strong> Laying <strong>of</strong> Hot Asphalt Road<br />

Surfacing.<br />

R5<br />

KERBING<br />

R5.1 General<br />

Cast in-situ kerbing shall be constructed using extruded concrete <strong>and</strong> finished as required in AS2876<br />

concrete kerb <strong>and</strong> channel (gutters).<br />

Cross section <strong>of</strong> kerbing shall be in accordance with detail drawings show on the drawings.<br />

R5.2 Placement<br />

Construction shall be carried out in approved method <strong>and</strong> shall be extruded <strong>and</strong> vibrated to give<br />

maximum density. Concrete strength shall develop a minimum twenty eight (28) day strength <strong>of</strong> 32<br />

MPa.<br />

The extruded kerb shall be laid on the freshly swept surface <strong>of</strong> the primer sealed bitumen pavement,<br />

the surface is to be cleaned <strong>of</strong> all <strong>for</strong>eign or loose <strong>and</strong> broken pavement material.<br />

Finish to top <strong>and</strong> <strong>road</strong> face <strong>of</strong> kerb shall be uni<strong>for</strong>mly smooth <strong>and</strong> free from voids <strong>and</strong> air pockets.<br />

The line <strong>of</strong> the kerbing shall be parallel to the centre line <strong>of</strong> the <strong>road</strong> <strong>and</strong> the kerbing on both sides <strong>of</strong><br />

the <strong>road</strong> shall be exactly parallel to each other, unless shown otherwise on the drawings.<br />

All kerbing shall be laid to correct grades corresponding to the design grade <strong>of</strong> the <strong>road</strong> <strong>and</strong> radius<br />

sweeps <strong>and</strong> intersections.<br />

All kerbing on radii less than 30m shall be fully keyed into the pavement.<br />

All kerbing shall be protected by the Contractor from marking <strong>and</strong> from bitumen overspray.<br />

R5.3 Curing<br />

Kerbs shall be sprayed with Calcure "D" or equivalent curing membrane within two hours <strong>of</strong> surface<br />

finishing <strong>of</strong> the concrete.<br />

R5.4 Joints<br />

Kerbs shall be cut completely through to give 10mm expansion joint every 4.5 metres <strong>of</strong> kerb length.<br />

Immediately after extrusion, contraction joints shall be <strong>for</strong>med by a grooving tool at every 1.5 metres.<br />

A 10mm expansion joint shall be left either side <strong>of</strong> all <strong>road</strong> <strong>drainage</strong> gullies <strong>and</strong> tangent points <strong>of</strong> all<br />

curves.<br />

Specification <strong>for</strong> Subdivision Construction <strong>of</strong> Road Works <strong>and</strong> Drainage<br />

Rev. 1 – February 2013<br />

40