Vol 21 No. 1

Vol 21 No. 1

Vol 21 No. 1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

J Bagh College Dentistry <strong>Vol</strong>.<strong>21</strong>(1), 2009 Assessment of consistency …<br />

Compressive strength test: Specimens of the<br />

base materials with or with out CO 2 laser<br />

treatment were prepared as cylinders of 4mm in<br />

diameter and 6mm in length which prepared by<br />

using a stainless steel mold and kept in water bath<br />

at 37±1 0 C and 90-100% relative humidity at two<br />

intervals: 24 hours and 1 week (7days) after<br />

mixing .The compressive strength were<br />

determined by using compressive strength testing<br />

machine at speed of 1 mm/minutes, the load was<br />

applied on the long axis of the specimens .The<br />

compressive strength were measured for each<br />

specimen by detecting the force that caused early<br />

sign of fracture of the specimen.<br />

RESULTS<br />

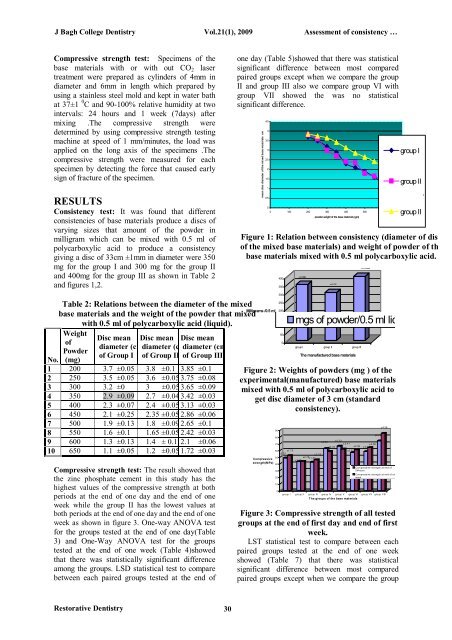

Consistency test: It was found that different<br />

consistencies of base materials produce a discs of<br />

varying sizes that amount of the powder in<br />

milligram which can be mixed with 0.5 ml of<br />

polycarboxylic acid to produce a consistency<br />

giving a disc of 33cm ±1mm in diameter were 350<br />

mg for the group I and 300 mg for the group II<br />

and 400mg for the group III as shown in Table 2<br />

and figures 1,2.<br />

one day (Table 5)showed that there was statistical<br />

significant difference between most compared<br />

paired groups except when we compare the group<br />

II and group III also we compare group VI with<br />

group VII showed the was no statistical<br />

significant difference.<br />

mean disc diameter of the mixed base materials cm<br />

4.5<br />

4<br />

3.5<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

0 100 200 300 400 500 600 700<br />

powder weight of the base materials (gm)<br />

group I<br />

group II<br />

group II<br />

Figure 1: Relation between consistency (diameter of disc<br />

of the mixed base materials) and weight of powder of the<br />

base materials mixed with 0.5 ml polycarboxylic acid.<br />

400<br />

350<br />

±0.087<br />

±0.05<br />

±0.0289<br />

I<br />

250<br />

Table 2: Relations between the diameter of the mixed<br />

Milligrams /0.5 ml 200<br />

base materials and the weight of the powder that mixed<br />

150<br />

with 0.5 ml of polycarboxylic acid (liquid).<br />

100<br />

Weight<br />

50<br />

Disc mean Disc mean Disc mean<br />

of<br />

0<br />

diameter (cm) diameter (cm) diameter (cm)<br />

group I group II group III<br />

Powder<br />

of Group I of Group II of Group III<br />

The manufactured base materials<br />

<strong>No</strong>. (mg)<br />

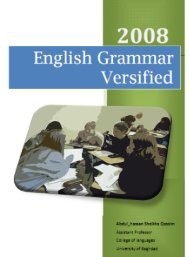

1 200 3.7 ±0.05 3.8 ±0.1 3.85 ±0.1 Figure 2: Weights of powders (mg ) of the<br />

2 250 3.5 ±0.05 3.6 ±0.05 3.75 ±0.08 experimental(manufactured) base materials<br />

3 300 3.2 ±0 3 ±0.05 3.65 ±0.09 mixed with 0.5 ml of polycarboxylic acid to<br />

4 350 2.9 ±0.09 2.7 ±0.04 3.42 ±0.03 get disc diameter of 3 cm (standard<br />

5 400 2.3 ±0.07 2.4 ±0.05 3.13 ±0.03<br />

consistency).<br />

6 450 2.1 ±0.25 2.35 ±0.05 2.86 ±0.06<br />

7 500 1.9 ±0.13 1.8 ±0.09 2.65 ±0.1<br />

±4.36<br />

90<br />

8 550 1.6 ±0.1 1.65 ±0.05 2.42 ±0.03<br />

±4.03<br />

80<br />

±2.33<br />

±2.52<br />

9 600 1.3 ±0.13 1.4 ± 0.172.1 ±0.06<br />

70<br />

±2.41<br />

±3.59<br />

±2.34<br />

± 2.09 ±3.8<br />

60 ±1.75<br />

±2.57<br />

10 650 1.1 ±0.05 1.2 ±0.05 1.72 ±0.03<br />

±2.07<br />

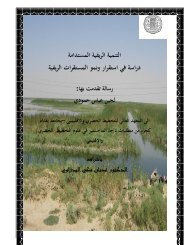

Compressive strength test: The result showed that<br />

the zinc phosphate cement in this study has the<br />

highest values of the compressive strength at both<br />

periods at the end of one day and the end of one<br />

week while the group II has the lowest values at<br />

both periods at the end of one day and the end of one<br />

week as shown in figure 3. One-way ANOVA test<br />

for the groups tested at the end of one day(Table<br />

3) and One-Way ANOVA test for the groups<br />

tested at the end of one week (Table 4)showed<br />

that there was statistically significant difference<br />

among the groups. LSD statistical test to compare<br />

between each paired groups tested at the end of<br />

Compressive<br />

strength(MPa)<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

300<br />

mgs of powder/0.5 ml liquid<br />

±2.35<br />

±2.78 ±1.84<br />

±2.32<br />

group I group II group III group IV group V group VI group VII group VIII<br />

The groups of the base materials<br />

Compressive strength at end of<br />

24hours<br />

Compressive strength at end of one<br />

week<br />

Figure 3: Compressive strength of all tested<br />

groups at the end of first day and end of first<br />

week.<br />

LST statistical test to compare between each<br />

paired groups tested at the end of one week<br />

showed (Table 7) that there was statistical<br />

significant difference between most compared<br />

paired groups except when we compare the group<br />

Restorative Dentistry<br />

30